Chain oiling device

A chain and equipment technology, applied in the field of chain processing equipment, can solve the problems of not being able to accurately know the oil remaining of the oil drum chain, not setting up monitoring equipment, affecting the use effect, etc., to achieve labor saving, high automation, and uniform oiling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

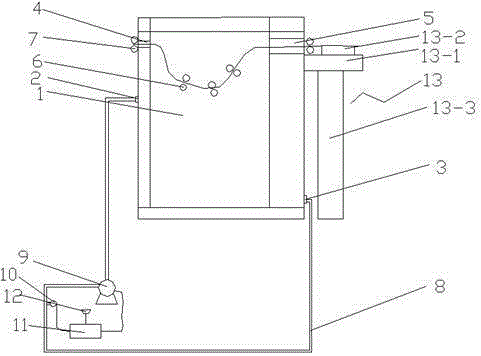

[0016] The present invention is a chain processing equipment, comprising an oil storage box 1 for storing chain oil, the upper part of the oil storage box 1 is provided with an oil inlet 2, and the lower part is provided with an oil outlet 3, and the oil storage box 1 is provided with a chain inlet 4 and the chain outlet 5, the inside of the oil storage tank 1 is provided with multiple groups of oil rollers 6 with different heights, the chain inlet 4 and the chain outlet 5 are respectively provided with guide rollers 7, and the oil outlet 3 of the oil storage tank 1 is connected by a pipeline The circulation pump 9 is connected to the oil inlet 2 on the oil storage tank through the oil return pipe, and a pressure gauge 10 is installed on the pipeline 8, and the low contact point of the pressure gauge 10 is connected to the signal input end of the controller 11, and the controller 11 The signal output terminal of the signal is connected with the motor of circulation pump 9.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com