Preparation method and application of complex microbial agent for removing nitrogen-containing pollutants in high-salinity wastewater

A technology of compound bacterial agent and high-salt wastewater, applied in the field of microorganisms, can solve the problems of poor impact load resistance, unstable treatment effect, high operating cost, etc., achieve low cost, overcome toxic effects, and solve the effects of biological nitrogen removal limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Step 1) Acclimatization of strains

[0059] Acclimatization of Rhodococcus crimson C1 (CCTCC NO: M 2019725) with high salt tolerance: take 2 mL of bacterial liquid and inoculate 250 mL of triangular medium containing 100 mL of sterilized CM medium (nitrate nitrogen concentration: 490mg / L) in a bottle, shake well, 30°C, 150 r min -1 Conditioned culture 3d. Under the same conditions as above, increase the concentration of NaCl and carry out continuous subculture for a total of 6 passages. The corresponding NaCl concentrations are 3%, 5%, 7%, 10%, 13%, and 15%.

[0060] High-salt tolerance acclimatization of Zoonococcus lepitoides (CICC 23939): Inoculate 2 mL of bacterial liquid into a 250 mL Erlenmeyer flask containing 100 mL of sterilized CM medium (nitrate nitrogen concentration: 490 mg / L) , shake well, 30°C, 150 r min -1 Conditioned culture 3d. Increase the NaCl concentration (the same as increasing the NaCl concentration of Rhodococcus crimson C1, the same below),...

Embodiment 2

[0079] Example 2: Efficient nitrogen removal experiment of compound bacterial agent in artificial wastewater with a salinity of 12%

[0080] The artificial wastewater formula is: sodium acetate 4g, NaNO 3 3g / L, KH 2 PO 4 0.35g / L, NaHCO 3 0.56g / L, the nitrogen concentration in the obtained artificial wastewater is 490 mg / L.

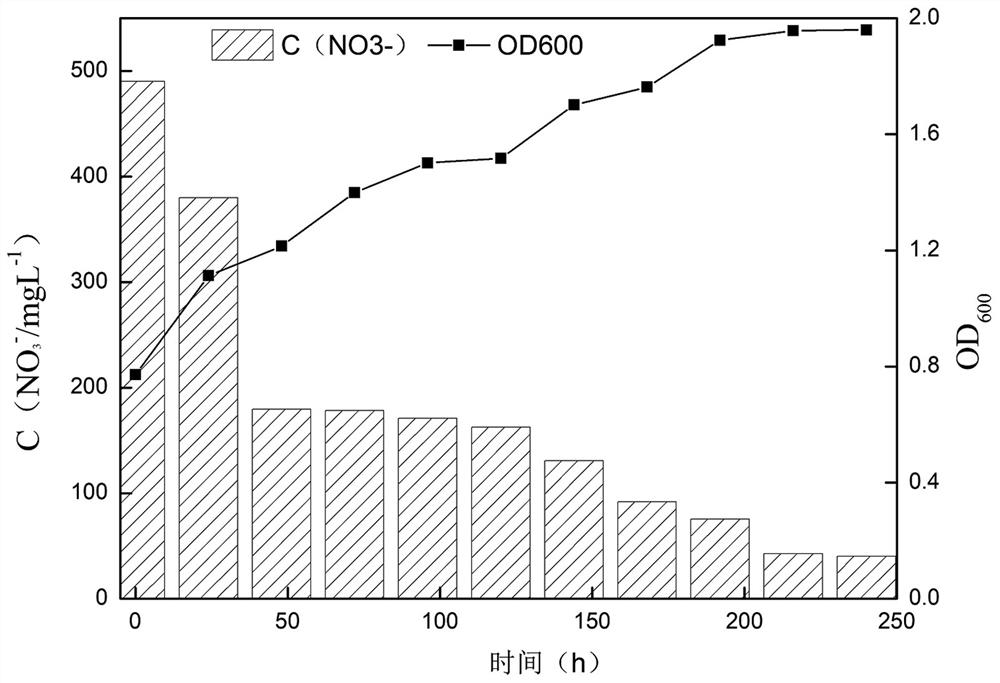

[0081] Take 100 mL of artificial wastewater in a 250 mL Erlenmeyer flask, and add 2 mL of compound bacterial agent solution (OD 600 0.9 to 1.2), sealed with a parafilm, placed in a shaker set at 30°C, 150 r min -1 conditions, and then measure the OD of the bacterial solution every 24 h 600 value to determine the growth of bacteria, and at the same time measure the content of nitrogen (nitrate) in the artificial wastewater to determine the removal effect of nitrogen. Depend on figure 1 It can be seen that the removal rate of nitrogen (nitrate) in artificial wastewater by the compound bacterial agent is as high as 91.2% under the condition of salini...

Embodiment 3

[0082] Example 3: Efficient Nitrogen Removal Experiment of Compound Bacteria at Different Salinity

[0083] The artificial wastewater formula is: sodium acetate 4g, NaNO 3 3g / L, KH 2 PO 4 0.35g / L, NaHCO 3 0.56g / L, the nitrogen concentration in the obtained artificial wastewater is 490 mg / L.

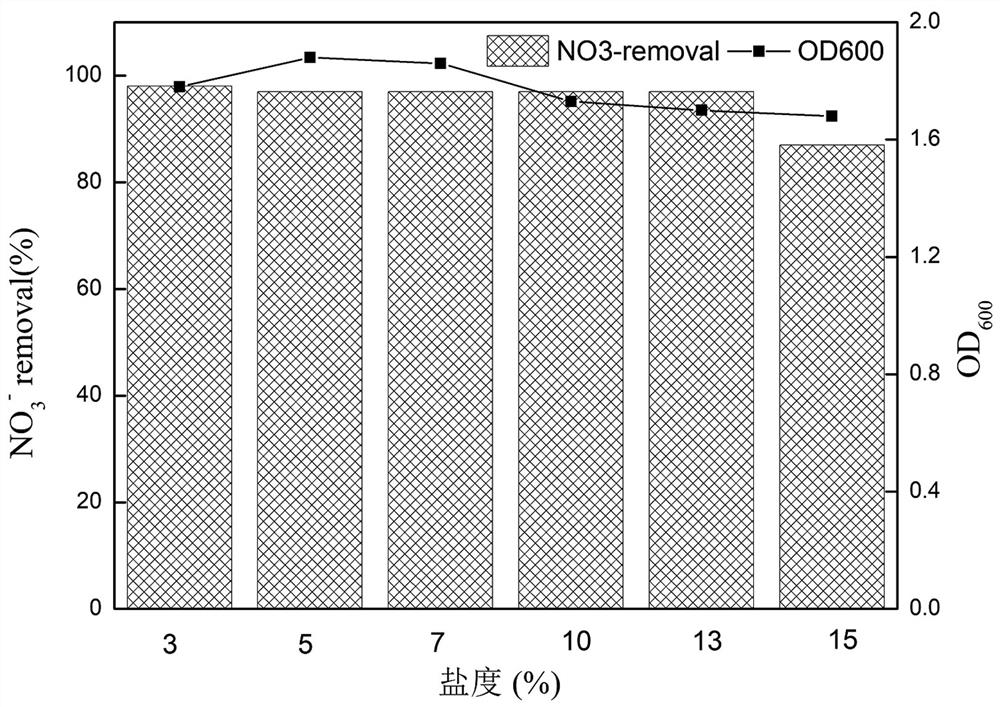

[0084] Take 100 mL of artificial wastewater in a 250 mL Erlenmeyer flask, and add 2 mL of compound bacterial agent solution (OD 600 1-2), sealed with parafilm, set different conical flasks to different salinities (3%, 5%, 7%, 10%, 13%, 15%), put them into the shaker and set at 30°C, 150 rpm -1 Cultivate under conditions, measure the OD of the bacterial solution 600 value to determine the growth of bacteria, and at the same time measure the content of nitrogen (nitrate) in the artificial wastewater to determine the removal effect of nitrogen.

[0085] Depend on figure 2 It can be seen that the composite bacterial agent can efficiently remove nitrogen (nitrate) in artificial waste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com