Preparation method of boron-modified phenolic aerogel

A boron-modified and aerogel technology is applied in the field of preparation of boron-modified phenolic aerogels to achieve the effects of improving ablation resistance, low reaction conditions, low thermal conductivity and density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Preparation of sol: dissolving novolac resin in absolute ethanol solution, stirring at room temperature for 3 hours to prepare a novolac ethanol solution with a mass fraction of 30 wt%. Subsequently, tributyl borate accounting for 20 wt% of the phenolic mass ratio was added to the above-mentioned phenolic ethanol solution and stirred for 1 hour to dissolve. Add 10 wt% of the cross-linking agent hexamethylenetetramine to the above mixed solution, and stir at room temperature for 2 hours to dissolve the hexamethylenetetramine, and the viscosity of the sol system remains unchanged.

[0050] (2) Sol-gel curing: the above clear solution was placed in a closed container, heated in an oven at 120° C., and boron-modified phenolic wet gel was obtained after sol-gel reaction for 12 hours.

[0051] (3) Atmospheric pressure drying: take out the wet gel, let it air naturally for 24 hours, and then dry it at 60 degrees Celsius under normal pressure for 12 hours to obtain an ablat...

Embodiment 2

[0054] (1) Preparation of sol: dissolving novolac resin in absolute ethanol solution, stirring at room temperature for 3 hours to prepare a novolac ethanol solution with a mass fraction of 25 wt%. Subsequently, triisopropyl borate accounting for 20 wt% of the phenolic mass ratio was added to the above-mentioned novolac ethanol solution and stirred for 1 h to dissolve. Add 10wt% crosslinking agent hexamethylenetetramine to the above mixed solution, and stir at room temperature for 2 hours to dissolve the hexamethylenetetramine, and the viscosity of the sol system increases to form a uniform suspension.

[0055] (2) Sol-gel curing: put the above suspension in a closed container, heat in an oven at 120° C., and obtain a boron-modified phenolic wet gel after sol-gel reaction for 12 hours.

[0056] (3) Atmospheric pressure drying: take out the wet gel, let it hang naturally for 24 hours, and then dry it at 60 degrees Celsius under normal pressure for 12 hours to obtain a boron-modi...

Embodiment 3

[0059] (1) Preparation of sol: dissolving novolac resin in absolute ethanol solution, stirring at room temperature for 3 hours to prepare a novolac ethanol solution with a mass fraction of 30 wt%. Then add triphenyl borate accounting for 25% by mass ratio of phenolic formaldehyde and stir and dissolve for 1 h, add 10 wt % cross-linking agent hexamethylenetetramine accounting for phenolic mass ratio to the above mixed solution, stir at room temperature for 2 hours to make hexamethylenetetramine Dissolve to obtain a homogeneous suspension.

[0060] (2) Sol-gel curing: put the above suspension in a closed container, heat in an oven at 120° C., and obtain boron carbide composite boron phenolic wet gel after sol-gel reaction for 12 hours.

[0061] (3) Atmospheric pressure drying: take out the wet gel, let it hang naturally for 24 hours, and then dry it at 60 degrees Celsius under normal pressure for 12 hours to obtain a boron-modified phenolic airgel product.

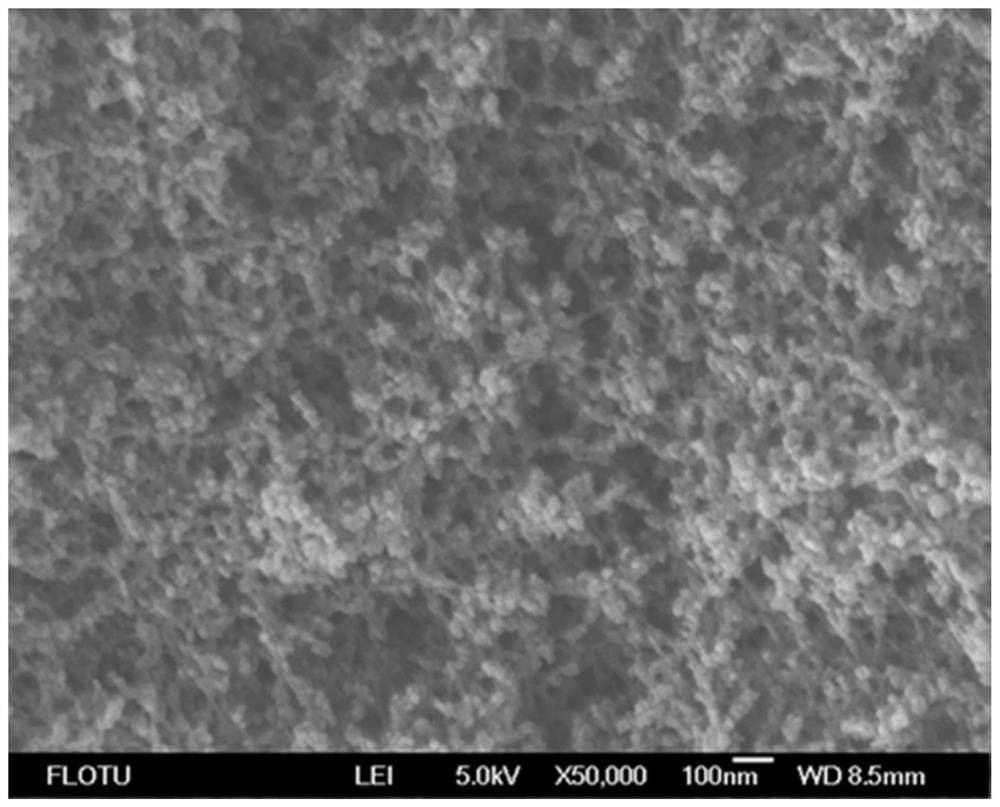

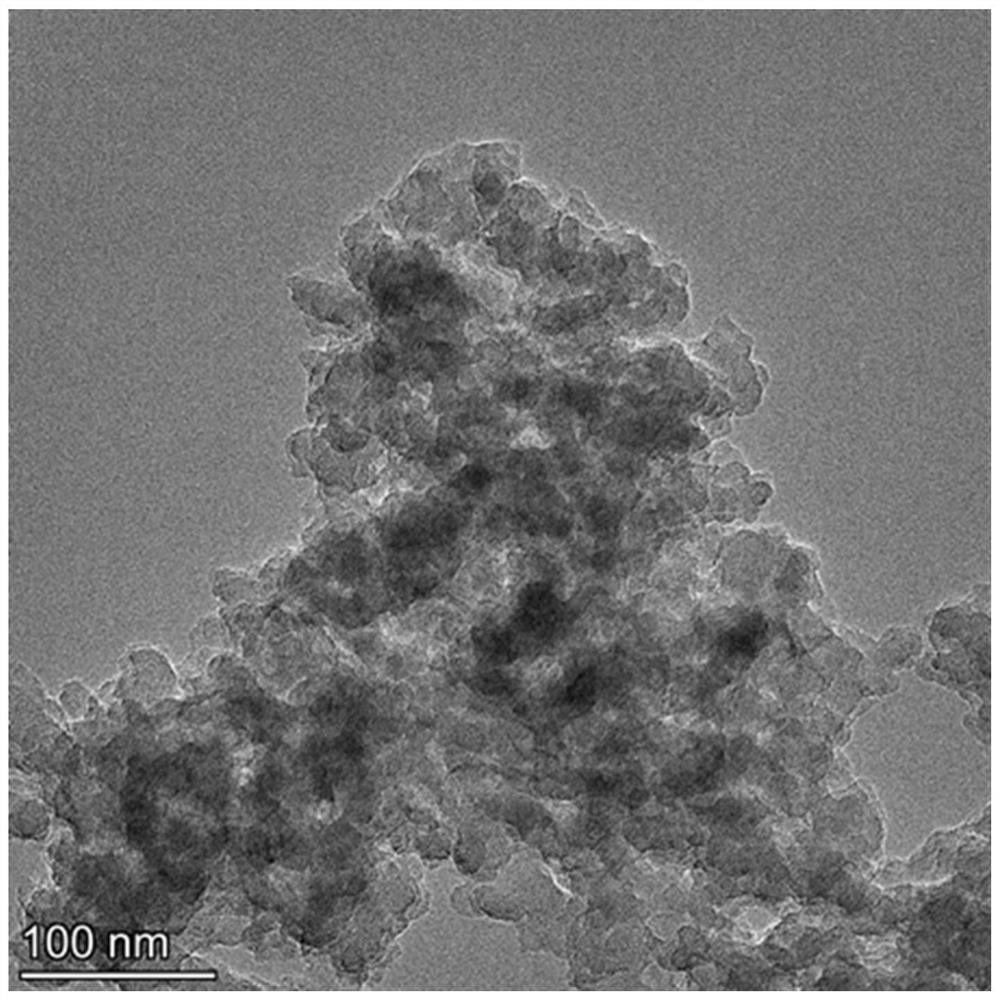

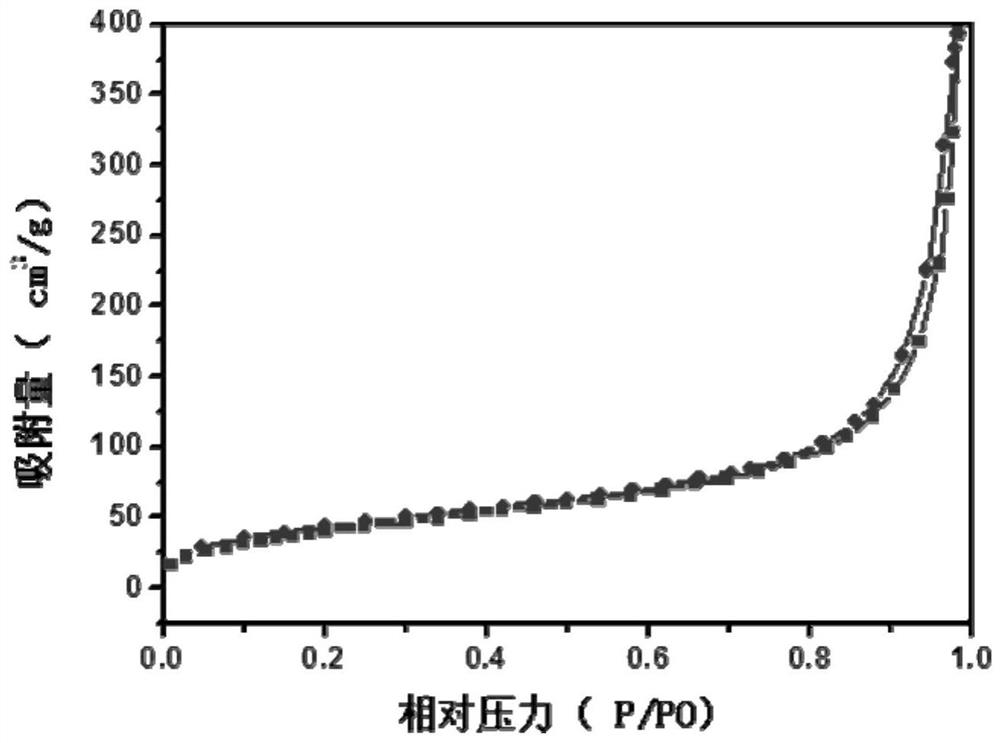

[0062] Scanning ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com