Baking-free brick and preparation method thereof

A technology of avoiding burning bricks and construction dregs, which is applied in the field of environmental protection building materials, can solve the problems of detachment of quick joints and connecting pipes, and achieve the effects of enhancing strength, preventing internal dry cracks, and accelerating curing and molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

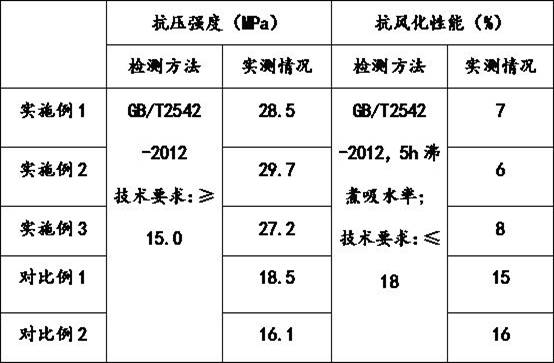

Examples

Embodiment 1

[0034] A non-burning brick is composed of the following raw materials in parts by weight:

[0035] 800 parts of construction dregs;

[0036] 200 parts of rice field straw;

[0037] 80 parts of cement;

[0038] 22 parts of slaked lime;

[0039] 25 parts of gypsum;

[0040] 8 parts of curing agent;

[0041] Active agent 3 parts;

[0042] 1 part anti-weathering agent;

[0043] 100 parts of water.

[0044] Construction dregs are waste dregs from construction sites, and the cement is ordinary Portland cement with a grade label of 42.5 or 52.5; the curing agent is composed of the following components, by weight percentage, 25% magnesium oxide, 25% green alum, and 25% alum , aluminum sulfate 15%, sodium phosphate 10%, each raw material is dried until the surface adsorption water content of each raw material is not more than 1%, put into the crusher and crushed until the particle diameter is not more than 2mm; the active agent is sodium lignosulfonate; The anti-weathering agen...

Embodiment 2

[0054] A non-burning brick is composed of the following raw materials in parts by weight:

[0055] 900 parts of construction dregs;

[0056] 2,500 parts of rice field straw;

[0057] 100 parts of cement;

[0058] 25 parts of slaked lime;

[0059] 30 parts of gypsum;

[0060] 10 parts of curing agent;

[0061] Active agent 4 parts;

[0062] Anti-weathering agent 2 parts;

[0063] 125 parts of water.

[0064] Construction dregs are waste dregs from construction sites, and the cement is ordinary Portland cement with a grade label of 42.5 or 52.5; the curing agent is composed of the following components, by weight percentage, 25% magnesium oxide, 25% green alum, and 25% alum , aluminum sulfate 15%, sodium phosphate 10%, each raw material is dried until the surface adsorption water content of each raw material is not more than 1%, put into the crusher and crushed until the particle diameter is not more than 2mm; the active agent is sodium lignosulfonate; The anti-weathering...

Embodiment 3

[0074] A non-burning brick is composed of the following raw materials in parts by weight:

[0075] 1000 parts of construction dregs;

[0076] 300 parts of rice field straw;

[0077] 120 parts of cement;

[0078] 30 parts of slaked lime;

[0079] 35 parts of gypsum;

[0080] 12 parts of curing agent;

[0081] Active agent 5 parts;

[0082] 3 parts anti-weathering agent;

[0083] 150 parts of water.

[0084] Construction dregs are waste dregs from construction sites, and the cement is ordinary Portland cement with a grade label of 42.5 or 52.5; the curing agent is composed of the following components, by weight percentage, 25% magnesium oxide, 25% green alum, and 25% alum , aluminum sulfate 15%, sodium phosphate 10%, each raw material is dried until the surface adsorption water content of each raw material is not more than 1%, put into the crusher and crushed until the particle diameter is not more than 2mm; the active agent is sodium lignosulfonate; The anti-weathering ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com