Preparation method and application of precursor cobalt hydroxide

A technology of cobalt hydroxide and precursors, applied in cobalt oxide/cobalt hydroxide, chemical instruments and methods, cobalt compounds, etc., can solve the problems of single improvement method and limited effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

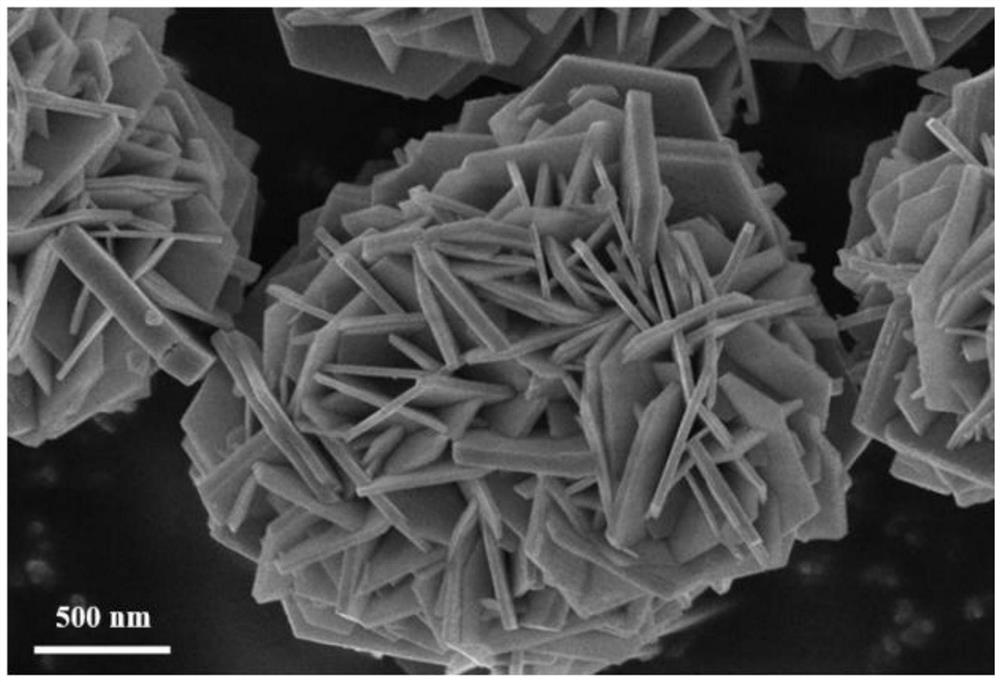

Image

Examples

Embodiment 1

[0033] The invention provides a method for preparing a precursor cobalt hydroxide, comprising the following steps:

[0034] S1, prepare cobalt salt solution, strong alkali solution and ammonia solution respectively; Specifically, this step preparation concentration is the cobalt sulfate solution of 2mol / L; The preparation concentration is the sodium hydroxide solution of 5mol / L; The preparation concentration is 5mol / L Ammonia solution;

[0035] S2. Add 5L of water to the reactor, heat the water in a water bath and keep it stable at 50°C, then add the strong alkali solution and ammonia solution prepared in step S1 into the reactor and keep it at a stable reaction temperature Stir evenly at high temperature to obtain a reaction bottom liquid with a pH (hydrogen ion concentration index) of 11.0 to 11.5 and an ammonia concentration of 0.4 to 0.8 mol / L; specifically, the reaction temperature described in this step is 45-55°C, and the technical solution Preferably it is 50°C; where...

Embodiment 2

[0042] The present invention also provides a method for preparing a positive electrode material for a fast-charging lithium-ion battery, comprising the following steps:

[0043] Mix the lithium salt, the compound containing W element, and the precursor cobalt hydroxide prepared in Example 1, and then raise the calcination temperature to 820°C to 880°C at a heating rate of 2 to 3°C / min, and at 820°C Calcining at ~880° C. for 17 to 20 hours to obtain the positive electrode material of nickel cobalt lithium manganese oxide. Specifically, in this step, the ratio of the amount of the Li element in the lithium salt to the amount of the precursor cobalt hydroxide is 1 to 1.1:1, and the ratio of the amount of the W element to the amount of the precursor cobalt hydroxide in the compound containing the W element The ratio is 0.00075~0.00085:1. The lithium salt is preferably lithium carbonate. The compound containing W element is nano-tungsten trioxide, ammonium metatungstate or ammoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com