Rapid sample piece structure of battery liquid cooling plate and manufacturing method thereof

A battery liquid and cold plate technology, applied in electrical components, secondary batteries, circuits, etc., can solve the problems of extended development cycle, scrapping, and increased investment costs, so as to reduce investment costs, shorten manufacturing cycles, and shorten development cycles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

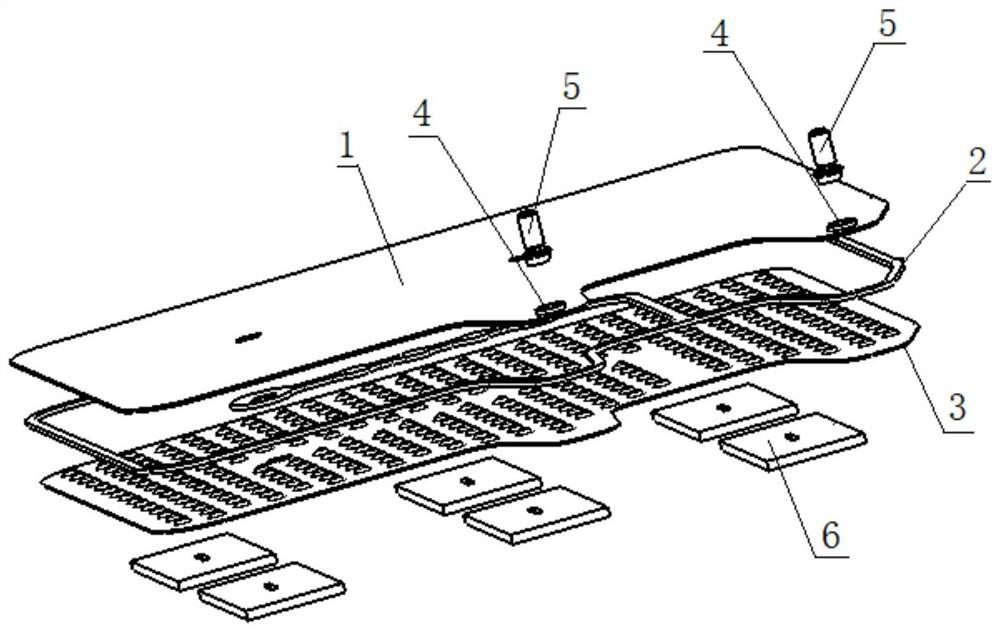

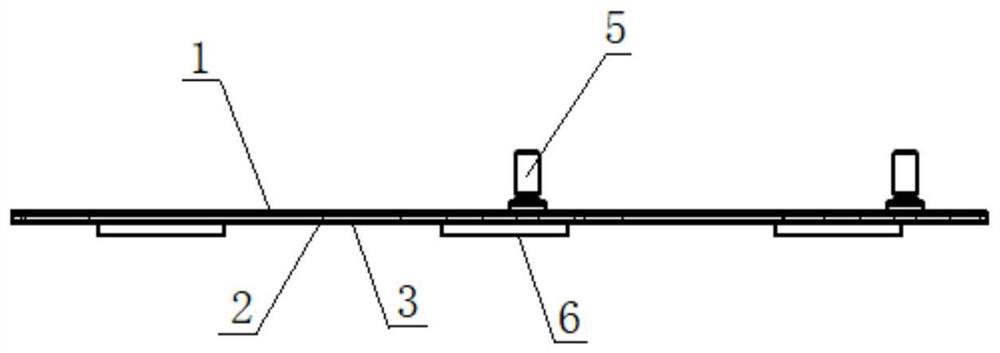

[0035] like figure 1 and figure 2 As shown, the rapid prototype structure of the battery liquid cold plate of the present invention includes three layers of bottom plate 1, middle frame 2 and cover plate 3 in sequence. The outer contour of the cover plate 3 is designed with a standard matrix conical bump matrix structure. The outline shape of the bottom plate 1 is designed according to the layout of the battery module. There are two punching holes 4 with flanges on the bottom plate 1. The punching holes 4 are connected with metal male connectors 5, and the two metal male connectors 5 are respectively connected to the coolant inlet and the coolant outlet. The bottom plate 1, the middle frame 2, the cover plate 3 and the metal male connector 5 are integrally welded on Together.

[0036] Among them, the surface of the middle frame 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com