PDDA protonated graphite phase carbon nitride, preparation method and application thereof

A technology of graphite phase carbon nitride and protonization, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problems of weak adsorption capacity of anionic dyes, achieve good adsorption effect, and prepare The scheme is simple and easy, and the effect of high adsorption selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] This embodiment provides a PDDA protonated graphite phase carbon nitride, and the PDDA protonated graphite phase carbon nitride is prepared by the following preparation method:

[0061] (1) Put 3.0g of melamine into a crucible with a cover, place it in a muffle furnace and raise the temperature to 550°C at a heating rate of 5°C / min, then calcinate at 550°C for 2h, then grind again, use 50wt % ethanol aqueous solution for washing, and finally dried at 80°C for 12h to obtain graphite phase carbon nitride;

[0062] (2) Dissolve 10mL of polydimethyldiallylammonium chloride in 100mL of deionized water, then add 1.0g of graphitic carbon nitride, ultrasonically disperse at 250W for 10min, and heat and stir at 60°C for 4h , centrifuged at 8000r / min for 3min, washed with water, and finally dried at 80°C for 12h to obtain PDDA protonated graphitic carbon nitride.

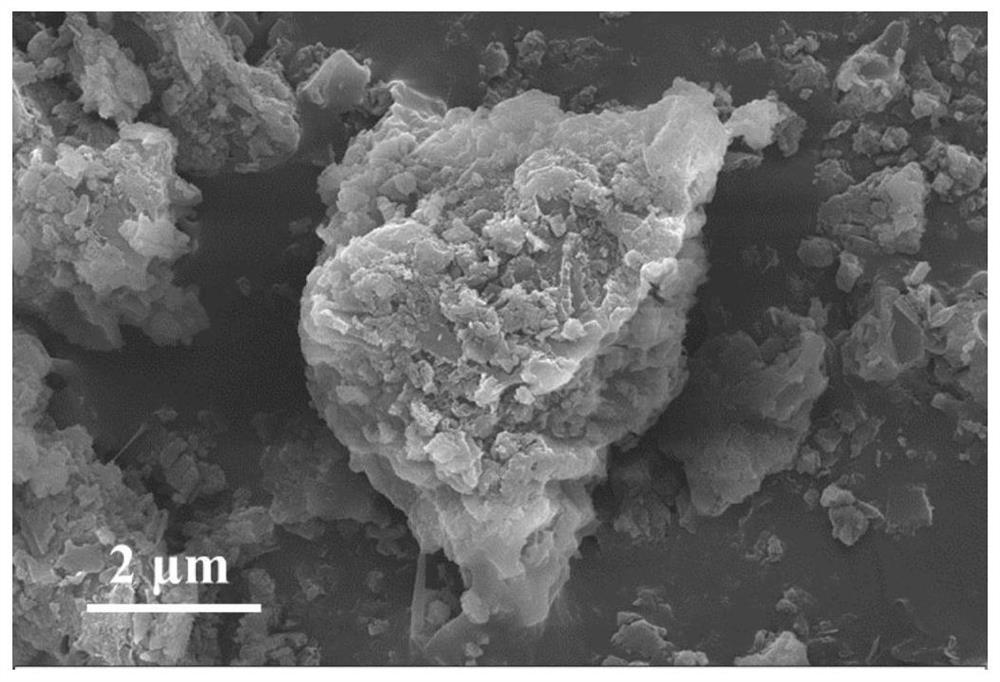

[0063] figure 1 For the microscopic morphology of the PDDA protonated graphite phase carbon nitride prepared in Ex...

Embodiment 2

[0065] This embodiment provides a PDDA protonated graphite phase carbon nitride, and the PDDA protonated graphite phase carbon nitride is prepared by the following preparation method:

[0066] (1) Mix 3.0 g of melamine with 0.3 g of potassium oxalate, grind them evenly, put the resulting solid mixture into a crucible with a cover, and place it in a muffle furnace to raise the temperature to 550 °C at a heating rate of 5 °C / min , and then calcined at 550°C for 2h, grind again, wash with 0.1M hydrochloric acid aqueous solution and 50wt% ethanol aqueous solution in turn until the pH of the calcined product is 7.0, and finally dry at 80°C for 12h to obtain graphite phase nitrogen carbonization;

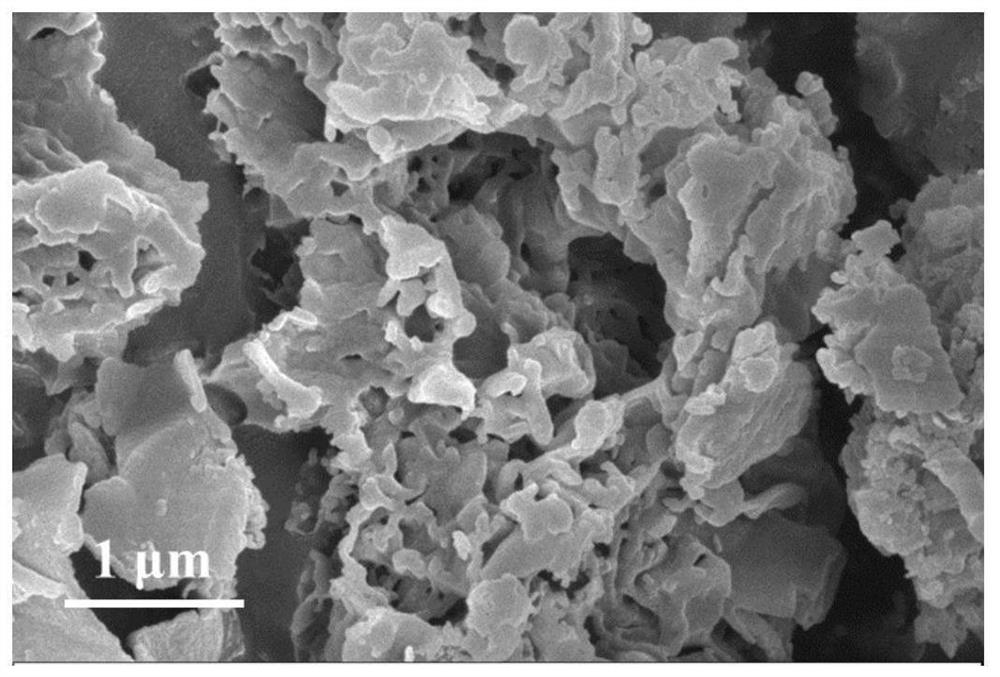

[0067] (2) Dissolve 10mL of polydimethyldiallylammonium chloride in 100mL of deionized water, then add 1.0g of graphitic carbon nitride, ultrasonically disperse at 250W for 10min, and heat and stir at 60°C for 4h , centrifuged at 8000r / min for 3min, washed with water, and finally dried a...

Embodiment 3

[0070] This embodiment provides a PDDA protonated graphite phase carbon nitride, and the PDDA protonated graphite phase carbon nitride is prepared by the following preparation method:

[0071] (1) Put 10.0g of urea and 0.5g of melamine into a crucible with a cover, place it in a muffle furnace and raise the temperature to 550°C at a heating rate of 5°C / min, then calcinate at 550°C for 2h, and then proceed to Grinding, washing with 50 wt% ethanol aqueous solution until the pH of the calcined product is 7.0, and finally drying at 80°C for 12 hours to obtain graphite phase carbon nitride;

[0072] (2) Dissolve 10mL of polydimethyldiallylammonium chloride in 100mL of deionized water, then add 0.5g of graphitic carbon nitride, ultrasonically disperse at 250W for 10min, and heat and stir at 60°C for 4h , centrifuged at 8000r / min for 3min, washed with water, and finally dried at 80°C for 12h to obtain PDDA protonated graphitic carbon nitride.

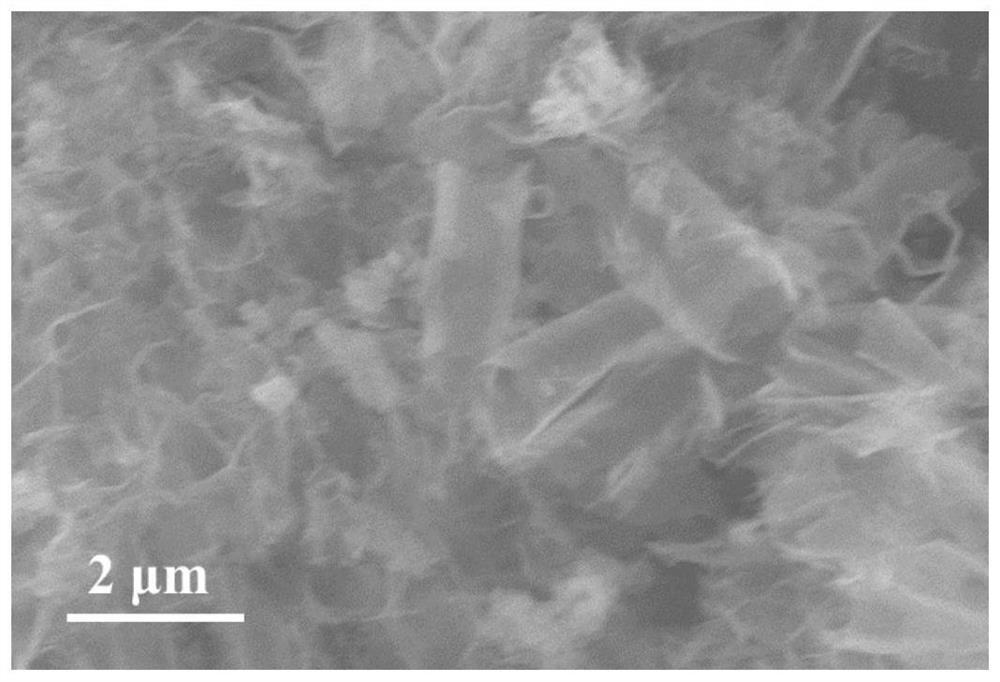

[0073] image 3 For the microscopic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com