Genetically engineered bacterium for producing L-menthol as well as construction method and application of genetically engineered bacterium

A technology of genetically engineered bacteria and menthol, applied in the field of metabolic engineering, can solve problems such as large quantities, single production method, slow market feedback, etc., and achieve the effects of overcoming limitations, fast market demand, and short cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Optimizing the endogenous MVA pathway

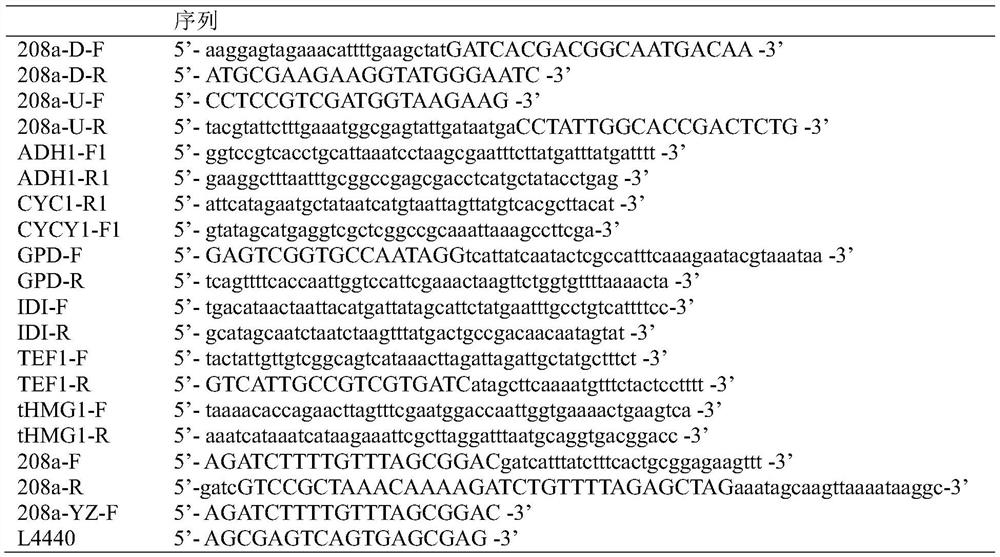

[0019] (a) Using the genome of Saccharomyces cerevisiae S288C as a template, use primers tHMG1-F and tHMG1-R to amplify gene tHMG1, tHMG1 is formed by removing the first 530 amino acid sequences of gene HMG1, and use primers GPD-F and GPD-R to amplify The promoter gene GPD (SEQ ID NO.11) was obtained, and the terminator gene ADH1-1 (SEQ ID NO.12) was obtained by amplification with primers ADH1-F1 and ADH1-R1; the amplification with primers IDI-F and IDI-R Obtain gene IDI, adopt primer TEF1-F, TEF1-R amplification obtains promoter gene TEF1 (SEQ ID NO.13), adopts primer CYC1-F1, CYC1-R1 amplification obtains terminator gene CYC1-1 (SEQ ID NO.13) .14), use primers 208a-D-F, 208a-D-R to amplify to obtain gene fragment 208a-D, and use primers 208a-U-F, 208a-U-R to amplify to obtain gene fragment 208a-F.

[0020] (b) divide the six fragments tHMG1, GPD, ADH1-1 and IDI, TEF1, CYC1-1 gene fragments obtained in step (a) into t...

Embodiment 2

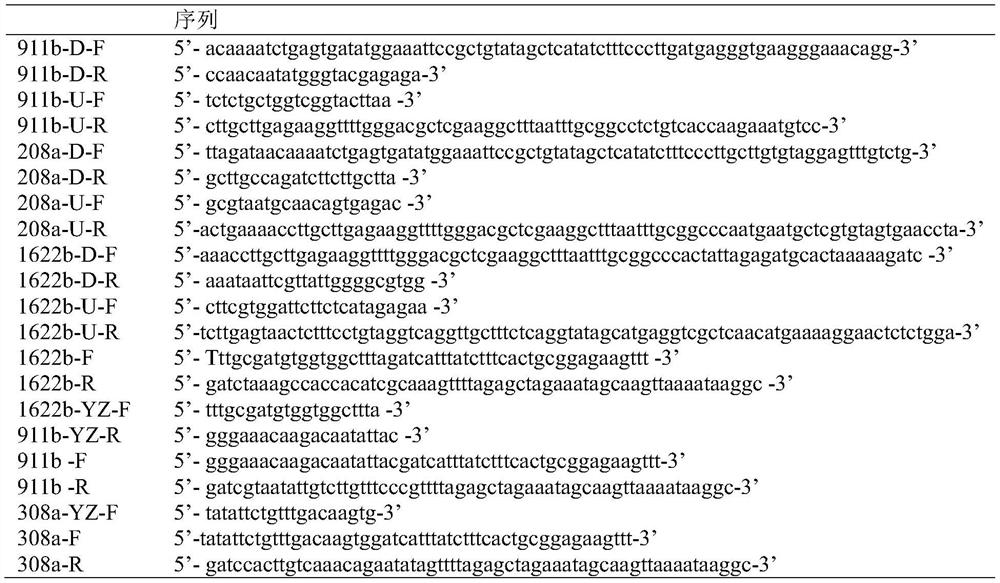

[0026] Example 2: Reconstruction of L-menthol metabolic synthesis pathway

[0027] (a) Artificially synthesized gene fragment P GAL1 -tLIS -T ADH1 -P GAL10 -L3H-T CYC1 -P GAL7 -CPR-T TDH3 ,P GAL1 -IPDH-T ADH1 -P GAL10 -IPR-T CYC1 -P GAL7 -KSI-T TDH3 ,P GAL1 -PGR-T ADH1 -P GAL10 -MMR-T CYC1 , wherein the tLIS gene is formed by removing the first 56 amino acid sequences of the gene LIS. Using the genome of Saccharomyces cerevisiae S288C as a template, use primers 911b-U-F, 911b-U-R to amplify the gene fragment 911b-U, use primers 911b-D-F, 911b-D-R to amplify the gene fragment 911b-D, use primers 308a-U-F, 308a-U-R amplified to obtain gene fragment 308a-U, using primers 308a-D-F, 308a-D-R to amplify to obtain gene fragment 308a-D, using primers 1622b-U-F, 1622b-U-R to amplify to obtain gene fragment 1622b-U, using primers 1622b-D-F, 1622b-D-R were amplified to obtain the gene fragment 1622b-D.

[0028](b) Using the plasmid pML104 as a template, using primers 308...

Embodiment 3

[0034] Embodiment 3: Utilize genetic engineering bacterial strain WMT4 to ferment and produce L-menthol

[0035] Inoculate a single colony of WMT4 on a solid YPD plate in 2ml of YPD medium, culture at 220rpm for 16-20 hours at 30°C, and then insert 1% of the inoculum into a 250mL round-bottomed shaker flask containing 25mL of YPD liquid medium, at 30°C, Cultivate at 220rpm for 96h. When fermenting to 16h, add 10% galactose aqueous solution. After the fermentation, 600 μL of the bacterial liquid was added to 0.5 mm glass beads and an equal volume of ethyl acetate to break up, and then the upper ethyl acetate layer was taken by high-speed centrifugation for detection by gas chromatography-mass spectrometry. The fermentation yield of L-menthol was 5.03 mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com