Antibacterial adhesive cement for head-wrapping reinforced layer of cotton canvas black upper of heat-vulcanized rubber shoe as well as preparation method and application of antibacterial adhesive cement

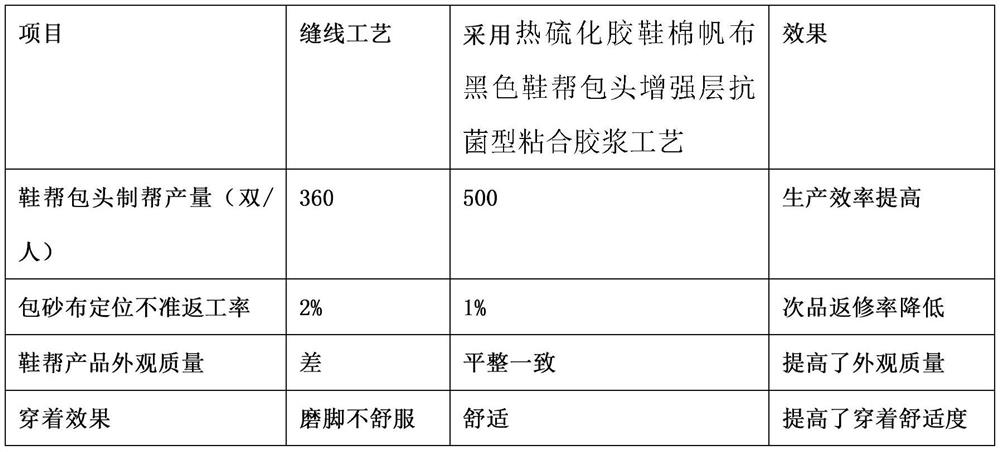

A technology of hot vulcanization and adhesive glue, applied in the direction of natural rubber adhesives, adhesives, adhesive types, etc., can solve the problems of poor wearing hygiene, uncomfortable wearing, and unsightly appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

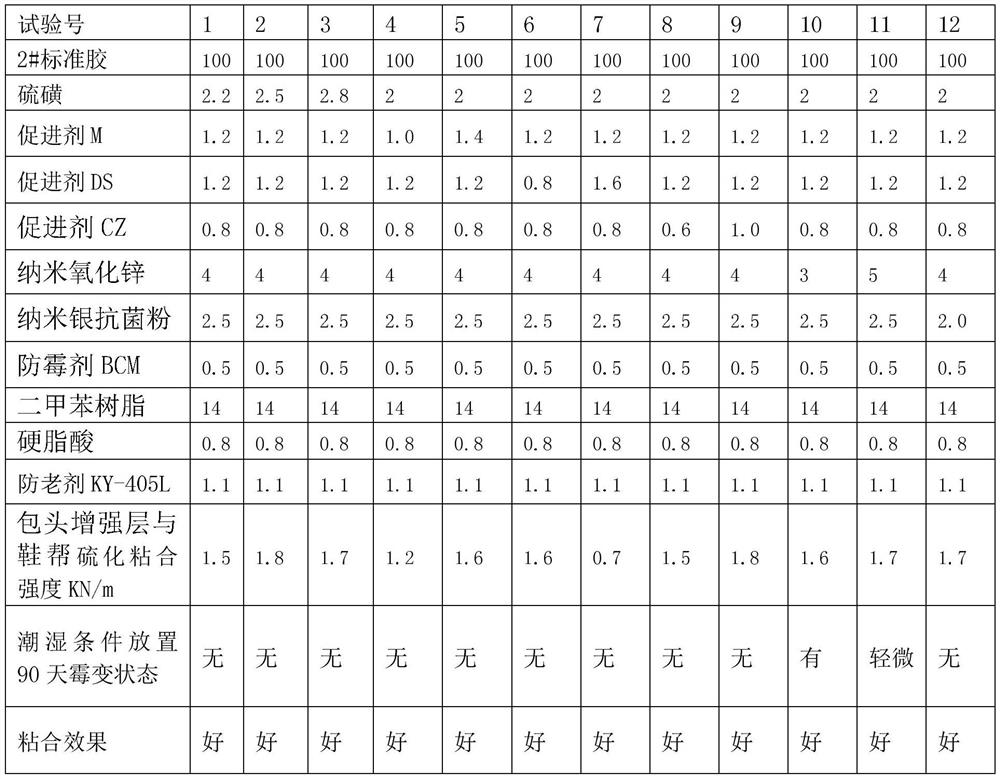

Embodiment 1

[0053] Example 1 raw materials: 100 parts of 2# standard glue, 2.5 parts of sulfur, 1.2 parts of accelerator M, 1.2 parts of accelerator DS, 0.8 part of accelerator CZ, 4 parts of nano-zinc oxide, 0.8 part of stearic acid, nano-silver Prepared with 2.5 parts of antibacterial powder, 14 parts of xylene resin, 0.5 part of antifungal agent BCM, 1.1 part of antiaging agent KY-405L, and 200 parts of 120# gasoline.

[0054] Preparation method: The first step is to make adhesive glue and plasticate rubber: take 80 parts of 2# standard glue on an open rubber mixer, and pass it through the machine for 12 times at a rolling distance of 0.5-1mm and a rolling temperature of 40-60°C. Obtain glue glue plastic compound rubber.

[0055] The second step is to make the mixed rubber: 1.2 parts of accelerator M, 1.2 parts of accelerator DS, 0.8 parts of accelerator CZ, 4 parts of nano-zinc oxide, 0.8 part of stearic acid, 2.5 parts of nano-silver antibacterial powder, two Add 14 parts of toluene...

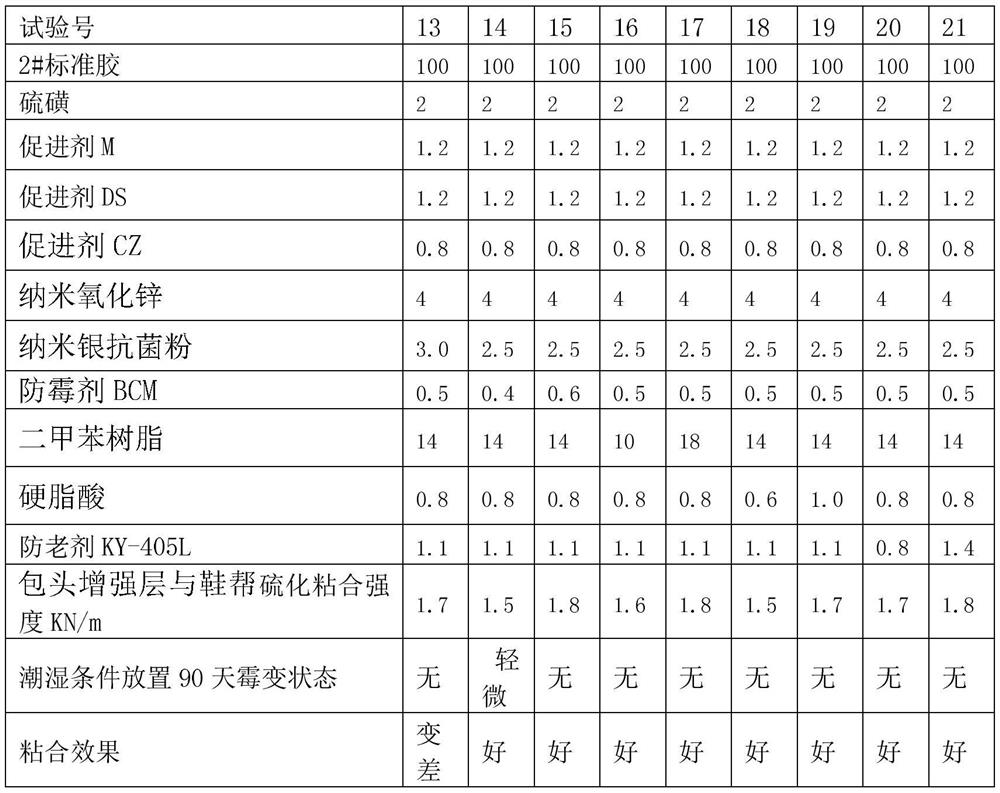

Embodiment 2

[0061] Example 2 Raw materials: 100 parts of 2# standard glue, 2.4 parts of sulfur, 1.0 parts of accelerator M, 1.4 parts of accelerator DS, 1.0 part of accelerator CZ, 5 parts of nano-zinc oxide, 1.0 part of stearic acid, nano 2.0 parts of silver antibacterial powder, 12 parts of xylene resin, 200 parts of 120# gasoline.

[0062] Preparation method: The first step is to make adhesive glue and plasticate rubber: take 80 parts of 2# standard glue on an open rubber mixer, and pass it through the machine for 12 times at a rolling distance of 0.5-1mm and a rolling temperature of 40-60°C. Obtain glue glue plastic compound rubber.

[0063] The second step is to make the mixed rubber: 1.0 parts of accelerator M, 1.4 parts of accelerator DS, 1.0 parts of accelerator CZ, 5 parts of nano-zinc oxide, 1.0 parts of stearic acid, 2.0 parts of nano-silver antibacterial powder, two Add 12 parts of toluene resin to 80 parts of adhesive mortar plasticized in the open mill, mix and discharge ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com