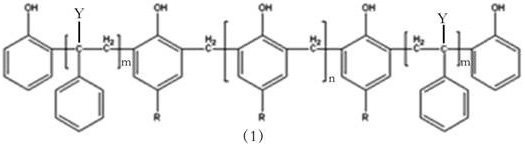

Grafted alkylphenol phenolic resin and preparation method thereof

A technology of grafted alkyl phenol and branched alkyl phenol, which is applied in the field of modified alkyl phenol phenolic resin and its preparation, to achieve the effects of reducing defective rate, wide application prospect and improving creep resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add 206.36g of 99.5 wt% p-tert-octylphenol and 3.0g of 98wt% concentrated sulfuric acid into the reaction kettle, heat up to melt p-tert-octylphenol, and start to drop 67.2g of 37wt% when the temperature reaches 100°C Aqueous formaldehyde solution was added dropwise to carry out esterification reflux reaction, the temperature was controlled at 110°C, and the reaction was carried out for 2.5 hours. When the material became viscous during the reaction, an appropriate amount of toluene solvent was added to dilute so that the reaction could be carried out evenly; after the reaction, 9.5g of 99wt % phenol was stirred and melted, and then slowly added dropwise 31.3g of styrene, the temperature was controlled at 110°C, and reacted for 2 hours after the dropwise addition was completed. After the reaction, remove the water brought by the solvent and formaldehyde under normal pressure, then raise the temperature to carry out the polycondensation reaction, dehydrate while reacting,...

Embodiment 2

[0032] Add 150.22g of 99.5wt% p-tert-butylphenol and 3.5g of 98wt% concentrated sulfuric acid into the reaction kettle, raise the temperature to 102°C and start adding 69.61g of 37wt% formaldehyde solution dropwise, and carry out esterification while dropping Reflux reaction, the temperature is controlled at 108 ° C, and the reaction is 3 hours. When the material becomes viscous during the reaction, add an appropriate amount of toluene solvent to dilute so that the reaction can be carried out evenly; Add 35.5 g of α-methylstyrene, the temperature is controlled at 108° C., and react for 1.5 hours after the dropwise addition is completed. After the reaction is completed, remove the solvent and the water brought in by formaldehyde under normal pressure, then raise the temperature to carry out the polycondensation reaction, dehydrate while reacting, and remove the water and residual toluene produced by the polycondensation reaction under vacuum. The temperature is controlled at ≤ 1...

Embodiment 3

[0034] Add 164.24g of 99.5wt% p-tert-amylphenol and 4.9g of 98wt% concentrated sulfuric acid into the reaction kettle, raise the temperature to 105°C and start adding 71.25g of 37wt% formaldehyde solution dropwise, and carry out esterification while dropping Refluxing reaction, the temperature is controlled at 109°C, during reaction 2, when the material becomes viscous during the reaction, add an appropriate amount of toluene solvent to dilute so that the reaction can be carried out evenly; 41.4 g of α-methylstyrene was added dropwise, the temperature was controlled at 109° C., and the reaction was carried out for 1 hour after the dropwise addition was completed. After the reaction, the solvent and the water brought in by formaldehyde are removed under normal pressure, and then the temperature is raised to carry out the polycondensation reaction, while the reaction is dehydrated, and the water and residual toluene produced by the polycondensation reaction are removed under vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com