Liquid evaporation device with thickening function

A technology of evaporation device and function, applied in the field of evaporators, can solve problems such as condensate reflux, achieve the effects of slow cooling speed, solve condensate reflux, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

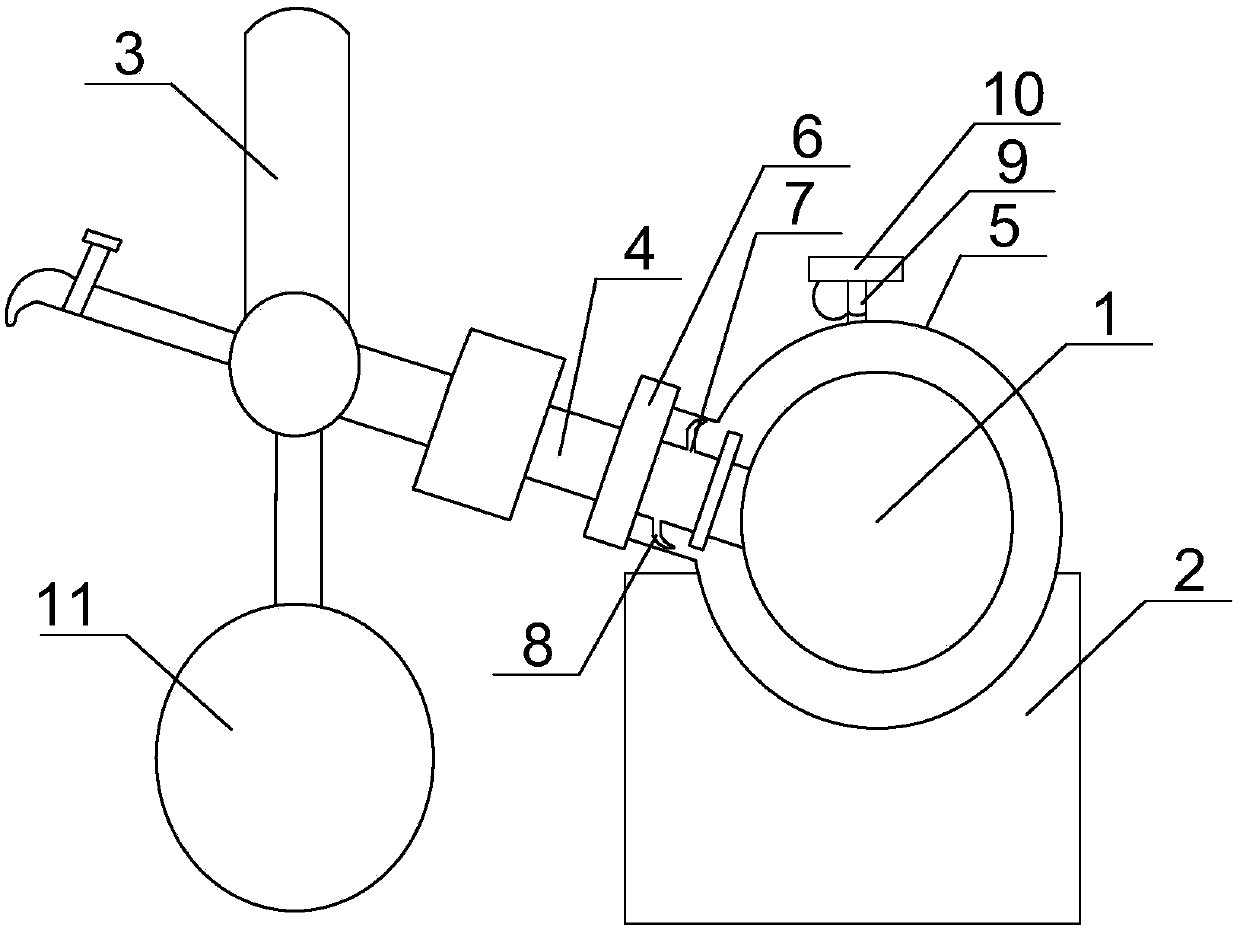

[0022] Such as figure 1 As shown, the solution evaporating device with thickening function of the present invention includes a rotary bottle 1, a driving device for driving the rotary bottle 1 to rotate, a water bath 2 for heating the rotary bottle 1, and a condensation pipe 3 communicated with the rotary bottle 1. The bottle 1 and the condenser tube 3 are connected through the evaporation tube 4, the outer part of the rotary bottle 1 is equipped with a set bottle 5, the rotary bottle 1 is located inside the set bottle 5, and the evaporator tube 4 is provided with a cork 6 connected to the set bottle 5. The stopper 6 is matched with the mouth of the set bottle 5, and the evaporating tube 4 passes through the soft stopper 6 and enters the set bottle 5 to communicate with the rotary bottle 1. The diameter of the neck of the bottle is larger than that of the rotary bottle 1 , and a plurality of openings 7 are arranged on the tube wall of the evaporation tube 4 , and the openings ...

Embodiment 2

[0025] Based on the first embodiment, the outer side of the evaporation tube 4 is provided with a conduit 8 communicating with the openings 7 one by one, and the outlet of the conduit 8 faces the inside of the set bottle 5 .

[0026] The conduit increases the flow path of the return condensate, so that the condensate is fully condensed, and the evaporated gas overflowing from the opening of the evaporator tube will enter the conduit and be condensed into condensed water in the conduit, which facilitates the recovery of condensed water.

Embodiment 3

[0028] Based on the above embodiment, the set bottle 5 is provided with a connecting pipe 9 communicating with the set bottle 5 , and the connecting pipe 9 is located outside the set bottle 5 . The connecting pipe 9 is provided with a plug 10 for blocking the mouth of the pipe, and the plug 10 is connected to the connecting pipe 9 through a connecting wire.

[0029] The connecting pipe is used for the liquid inlet and outlet of the sleeve bottle during the rotation process. The connecting wire is used to prevent loss of the plug.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com