Robot grinding and polishing system and method

A robot and grinding head technology, applied in the direction of grinding/polishing equipment, grinding machines, abrasive belt grinding machines, etc., can solve the problems of high labor intensity, harsh working environment, and high product cost, so as to improve product quality stability and reduce production The effect of stable cost and polishing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

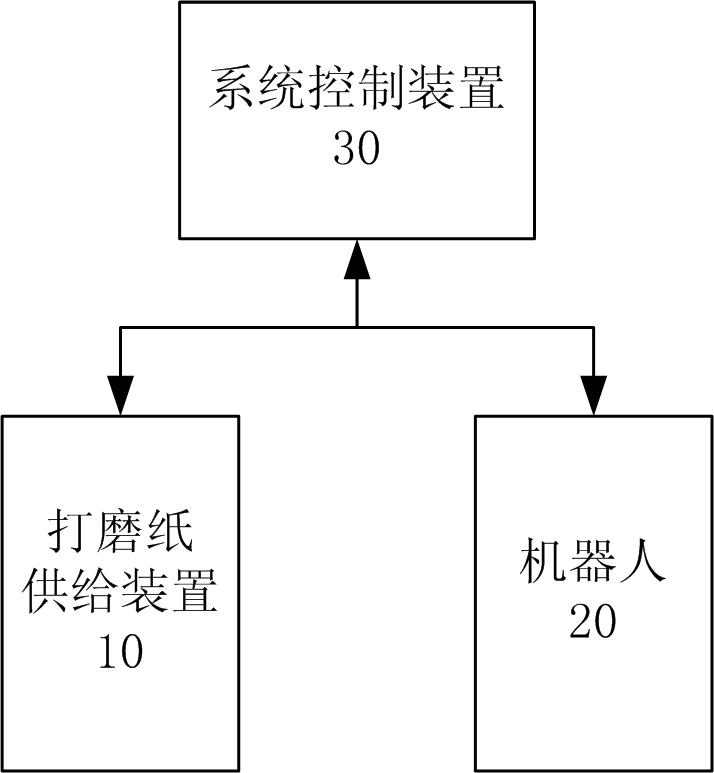

[0047] figure 1 It is a schematic diagram of the grinding and polishing system of the robot according to the present invention, such as figure 1 As shown, the robot grinding and polishing system of the present invention includes a grinding paper supply device 10, a robot 20, and a system control device 30, wherein,

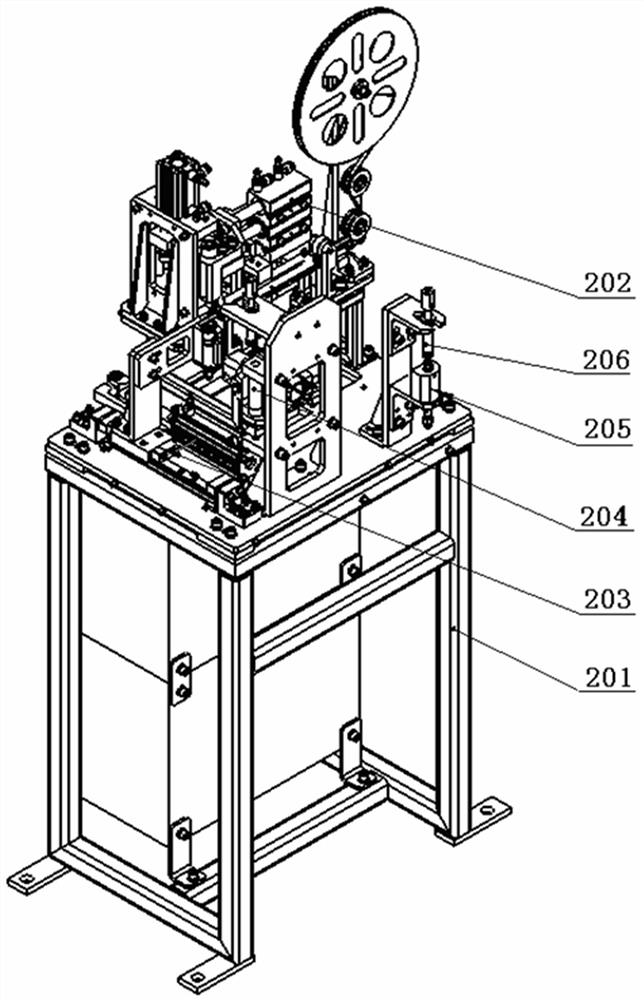

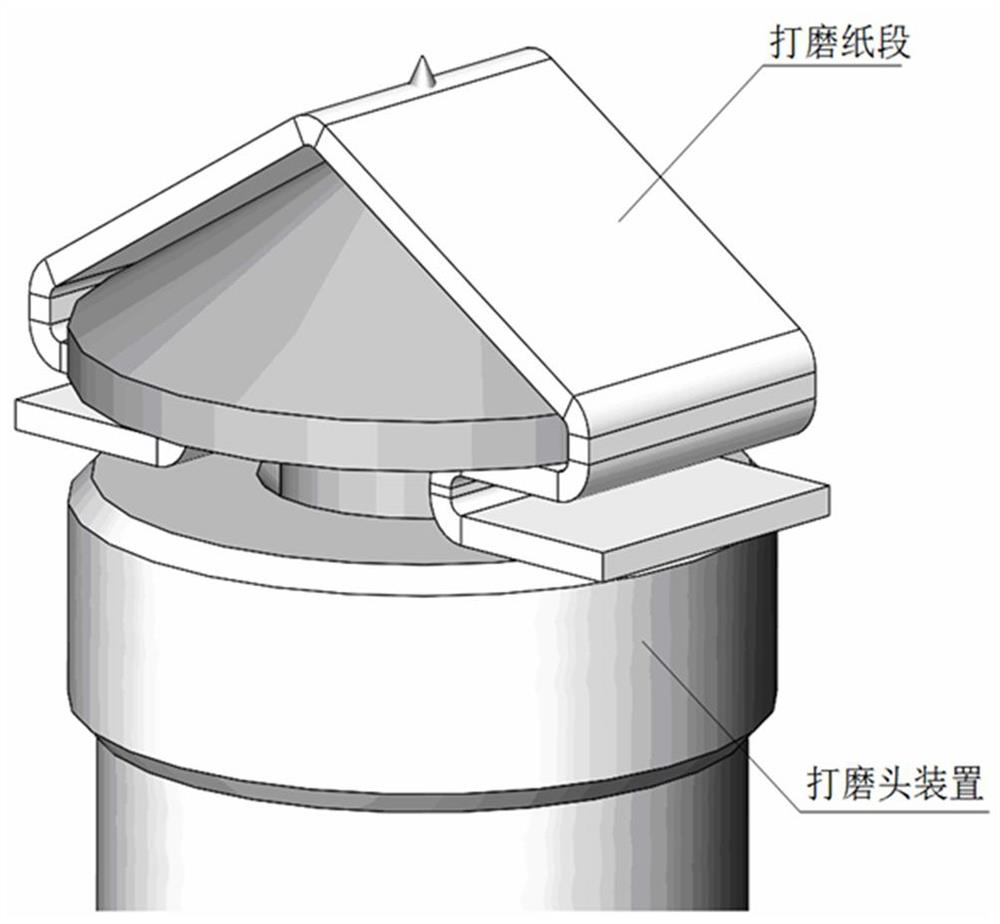

[0048] The grinding paper supply device 10 cuts the grinding paper belt from the grinding paper belt disc according to the preset length, and installs the cut grinding paper section on the grinding head device.

[0049] In the embodiment of the present invention, the grinding paper supply device 10 is also used to remove the grinding paper segment on t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap