Full-automatic adjustable fixture for flywheel casing of new energy automobile and machining technological process

A new energy vehicle, flywheel housing technology, applied in metal processing equipment, metal processing mechanical parts, clamping and other directions, can solve problems such as being unable to meet large-scale assembly line production, consuming a lot of manpower, and unable to ensure smooth and effective processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

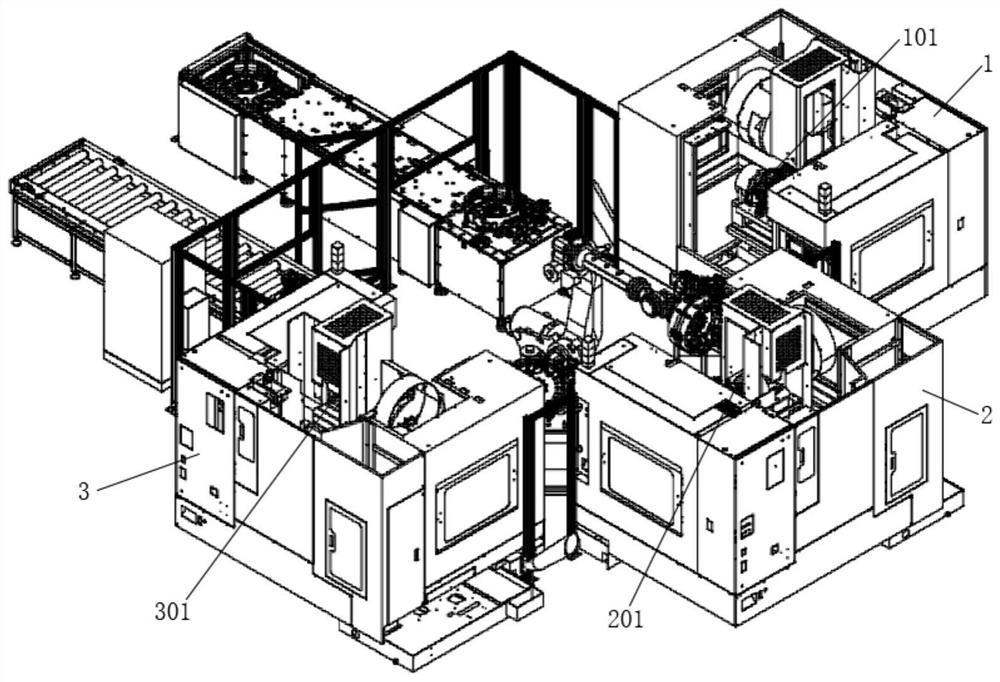

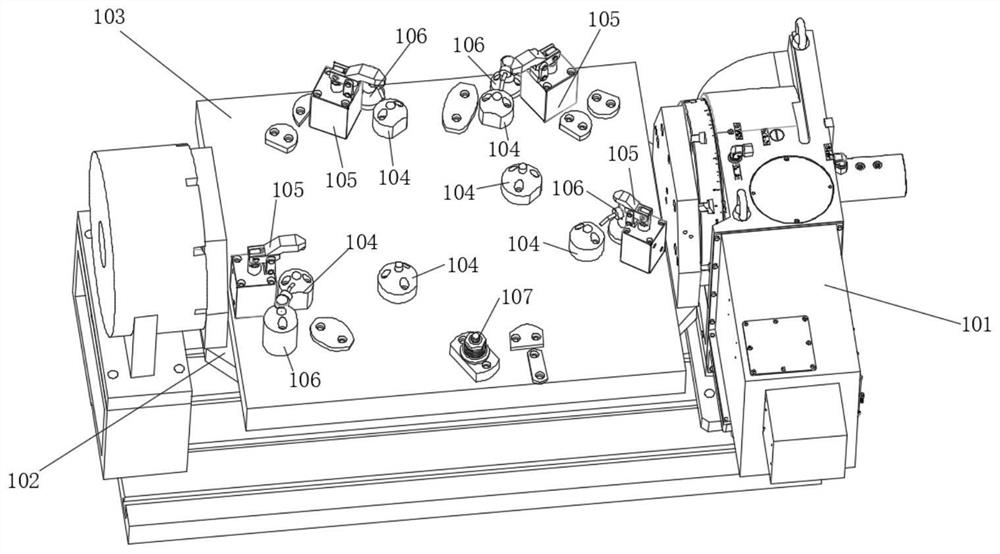

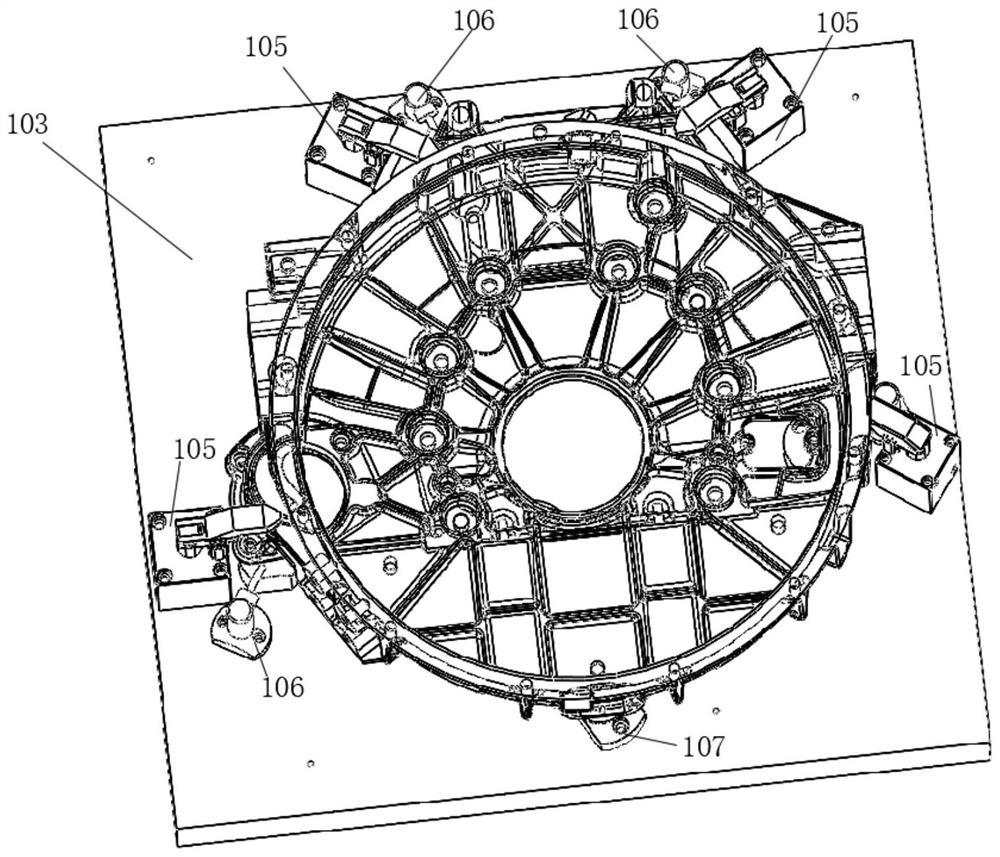

[0081] Embodiment 1: the fully automatic processing production line of the flywheel housing for new energy vehicles, such as figure 1 As shown, it includes the first processing station 101 arranged on the first turning-milling machine tool 1, the second processing station 201 arranged on the second turning-milling machine tool 2 and the third processing station arranged on the third turning-milling machine tool 3 Station 301, such as figure 2 and image 3 As shown, the first processing station 101 includes a first turntable 102 connected to the turntable at both ends, the first turntable 102 is provided with a first fixture panel 103, and the outer surface of the flywheel housing faces the first fixture panel 103. ; The surface of the first fixture panel 103 is provided with 6 first positioning pins 104, 4 first pressing members 105, 4 first air nozzles 106 and 1 first adjusting strut 107; One positioning pin 104 is respectively located at the four corners of the first fixt...

Embodiment 2

[0084] Embodiment 2: Utilize the fully automatic adjustable fixture for the flywheel housing of the new energy vehicle in Embodiment 1 to process the flywheel housing. The process is to place the unprocessed flywheel housing in the first processing station 101 of the first turning and milling machine tool 1 Carry out milling inner circle and flange surface, drilling and tapping, and countersinking on the second machining station 201 of the second turning and milling machine tool 2, and then carry out countersinking, drilling and tapping threaded holes, milling planes and drilling and tapping on the second processing station 201 of the second turning and milling machine tool Finally, on the third processing station 301 of the third turning and milling machine tool 3, fine milling of the joint surface, boring and drilling and tapping of the threaded holes is carried out, and the processing of the flywheel housing is completed after the three turning and milling operations are comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com