Construction method of temporary supports of beam slab post-cast strip

A temporary support and construction method technology, which is applied to the preparation of formwork/formwork/work frame, pillars, and building components on site, and can solve the problem of not being able to adapt to post-cast belt support, top plate post-cast belt and bottom plate post-cast belt Issues such as insufficient fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

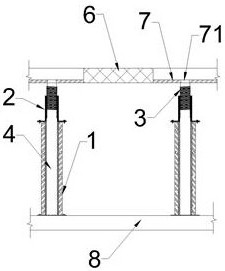

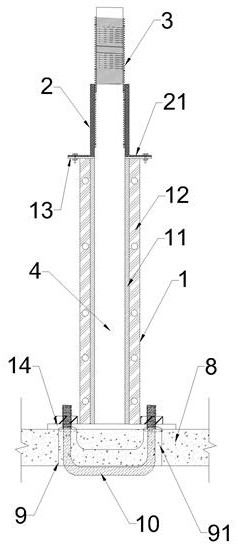

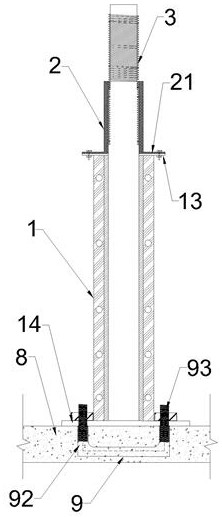

[0024]The method of construction with the temporary support after the casting slab according to this embodiment, comprising the steps of: S1, back strip 6 according to the design requirements, the profile of the temporary support after the rendering apparatus with pouring, the pouring belt along the temporary support means pouring belt 3 disposed longitudinal direction of the pitch, with cast slab formwork system 3 and located at the rear sides; back strip of the temporary support means comprises a support cylinder oriented by the lower set 1, the connecting tube 2 and the adjustment cylinder 3 the support tube 1 is a central steel support cylinder has a circular or rectangular through hole, the installation consists of a left and a right template from the template; the cartridge 2 is detachably connected to a support mounted on the cylinder 1, the adjustment cylinder 3 cartridge connecting sleeve 2, and is vertically movable and is positioned in the height direction of the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com