Motor rotor of permanent-magnetic synchronous tractor

A motor rotor and permanent magnet synchronous technology, applied in the direction of magnetic circuit rotating parts, manufacturing stator/rotor body, magnetic circuit shape/style/structure, etc., can solve the complicated processing of magnetic steel end plate, complex manufacturing process, positioning Poor precision and other problems, to achieve the effect of optimizing the fixing method, flexible and convenient installation, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention, and further describe the technical solution of the present invention in conjunction with the accompanying drawings, but the present invention is not limited to these embodiments.

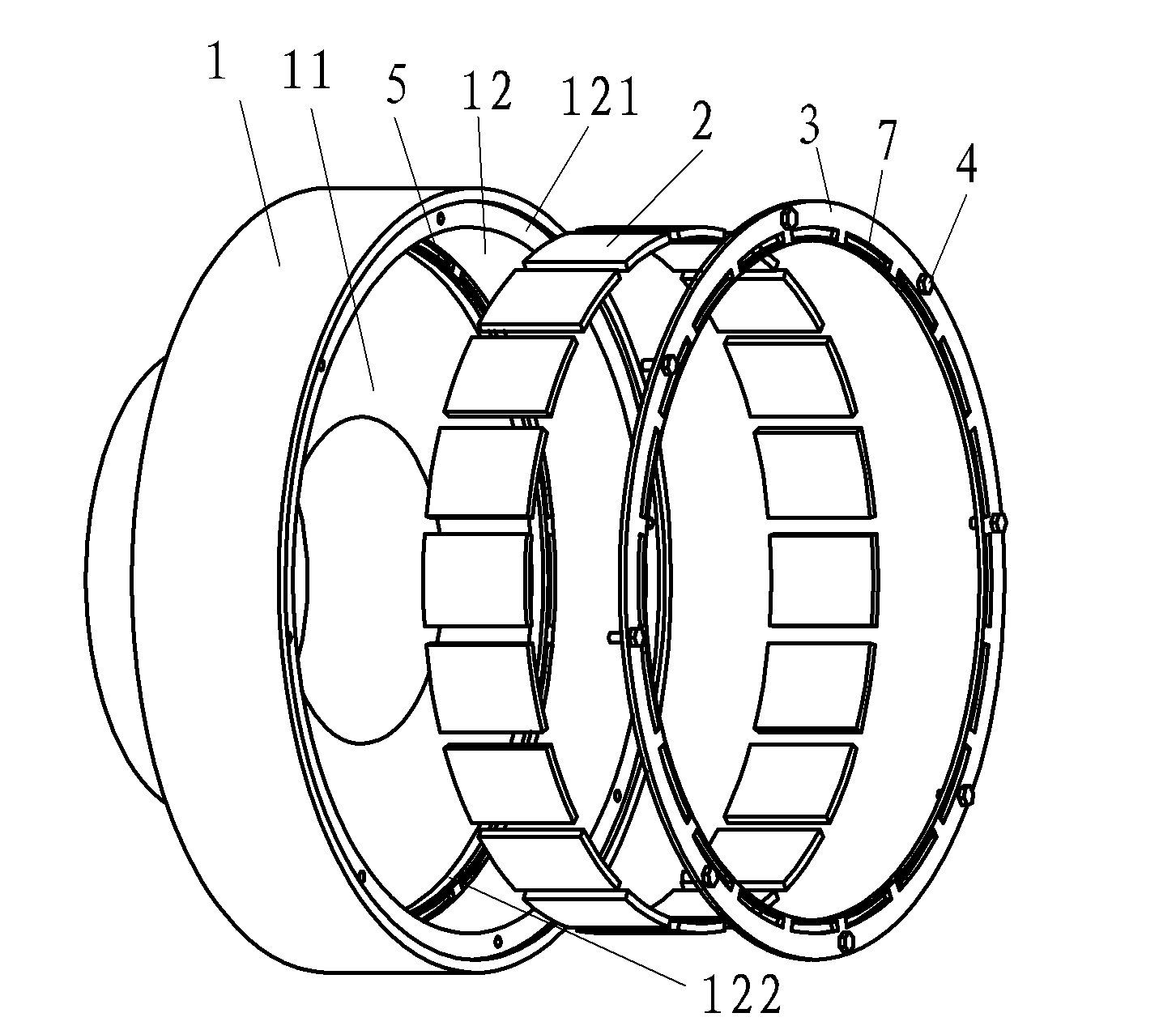

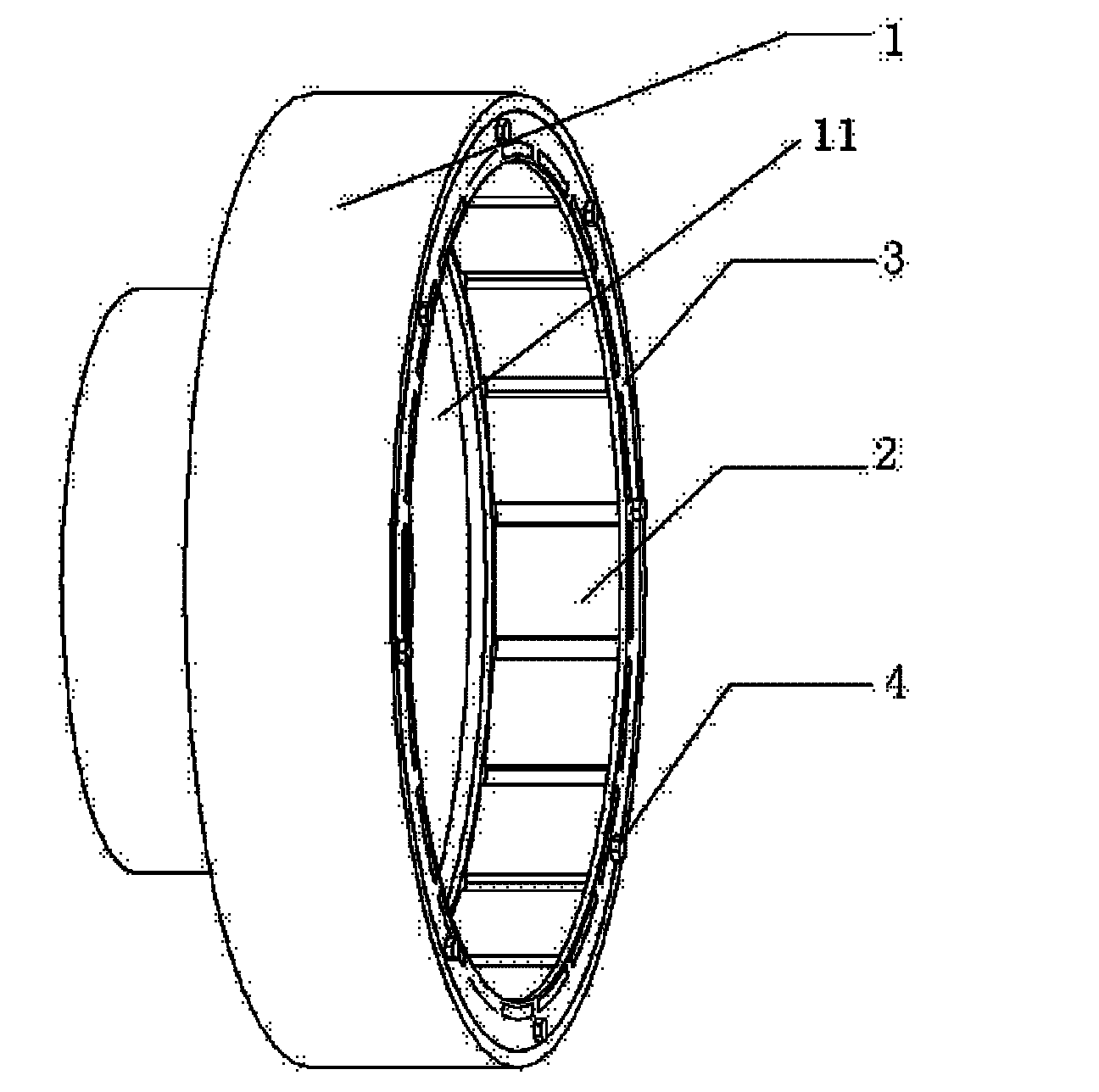

[0026] Such as figure 1 As shown, the motor rotor of the permanent magnet synchronous traction machine includes the rotor body 1, the magnetic steel 2, the outer magnetic steel end plate 3, the inner magnetic steel end plate 5 and the bolt 4, through the magnetic steel end plate 3 and the bolt 4, the The magnetic steel 2 is fixed on the rotor body 1 so that the magnetic steel can be kept from falling off even when the adhesive fails.

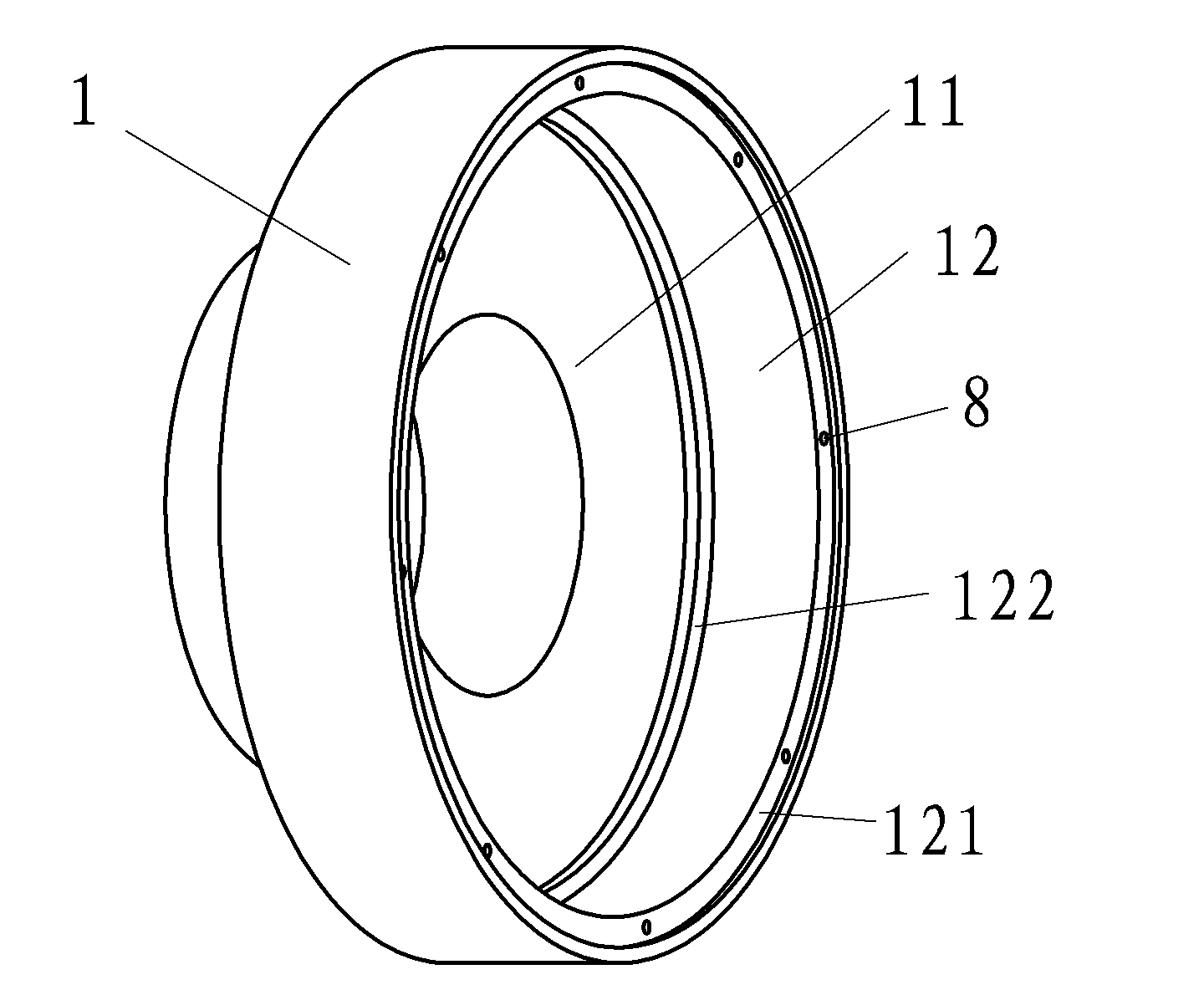

[0027] Specifically, image 3 It is the rotor body 1 of the present invention, and its inner cavity is composed of a stepped bottom surface 11 and an annular inner wall 12. An annular step 121 is arranged on the outer end surface of the annular inner wall 12. There are bolt holes 6 on the plane o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com