Forging press with buffering function for machining mechanical parts

A technology for mechanical parts and forging presses, applied in mechanical equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as body damage, and achieve the effect of reducing damage, strong overall linkage, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

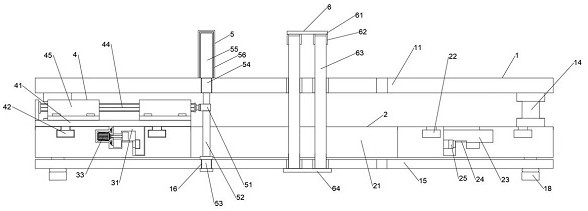

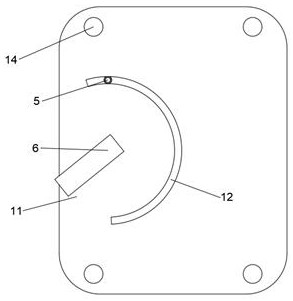

[0048] Such as Figure 1-Figure 9 As shown, the present invention provides a forging press for processing mechanical parts with a buffer function, including a frame mechanism 1, and the frame mechanism 1 includes a workbench 11 and a bottom plate 15, and between the workbench 11 and the bottom plate 15 The track mechanism 2, the track mechanism 2 includes a semi-circular rail plate 21, the semi-circular rail plate 21 is fixedly welded on the upper side panel of the base plate 15, and the upper side panel of the semi-circular rail plate 21 is excavated with a motor track groove 23, and the motor track groove 23 one side of the corresponding semi-annular rail plate 21 is excavated with an embedded rack 24, and the embedded rack 24 is away from the motor track groove 23. The corresponding semi-annular rail plate 21 is excavated with an annular slide rail 25 on the side of the motor track. The inside of the groove 23, the embedded rack 24 and the annular slide rail 25 is provided ...

Embodiment 2

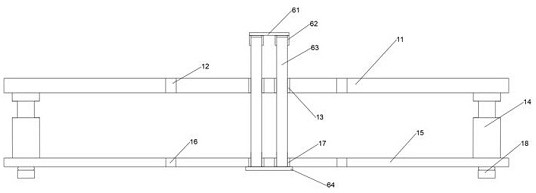

[0053] Such as Figure 1-2 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: a No. 1 pressing bar track groove 12 is drilled through the worktable 11 corresponding to the pressing bar mechanism 5, and the No. 1 pressing bar track groove 12 directly below corresponds to No. 2 push rod track groove 16 is drilled through the bottom plate 15 of the bottom plate, and a No. 1 ejector bushing 13 is drilled through the worktable 11 corresponding to the center of the semi-circular rail 21, and a bottom plate corresponding to No. 1 ejector bush 13 is drilled. No. 2 ejector bushing 17 is drilled through 15, and the four corners of the lower side panel of the worktable 11 and the four corners of the upper side panel of the bottom plate 15 are fixed and welded vertically through the middle liner 14 one by one. The four corners of the side panels are fixedly welded with bottom pads 18 , the bottom plate 15 is at the orthographic projection of the w...

Embodiment 3

[0057] Such as figure 1 , 4 As shown in and 5, on the basis of Embodiment 1, the present invention provides a technical solution: Preferably, the semi-annular rail plate 21 corresponding to the motor track groove 23 and the embedded rack 24 has a fitting groove inside , the depth of the annular slide rail 25 is greater than the depth of the fitting groove, the orientation of the annular slide rail 25 and the orientation of the embedded rack rail 24 are perpendicular to each other, and the embedded rack rail 24 faces directly upward, and the inner and outer sides of the motor track groove 23 Limiting track grooves 22 are drilled on the upper side panels of the corresponding semi-circular rail plates 21 .

[0058] In this embodiment, the notch on the semi-circular track plate 21 and the embedded rack 24 enable the track mechanism 2 and the power mechanism 3 to interact with each other, and play the role of an intermediate linkage component. This design makes the frame mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com