Adjustable hydraulic shock absorber

A hydraulic shock absorber and adjustable technology, which is applied in the direction of shock absorber, gas-hydraulic shock absorber, spring/shock absorber, etc., can solve the problems of interference in the shock absorption process and poor user experience of adjustable shock absorbers , to avoid interference, slow down the change of hydraulic oil flow rate, and reduce the effect of radial force deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

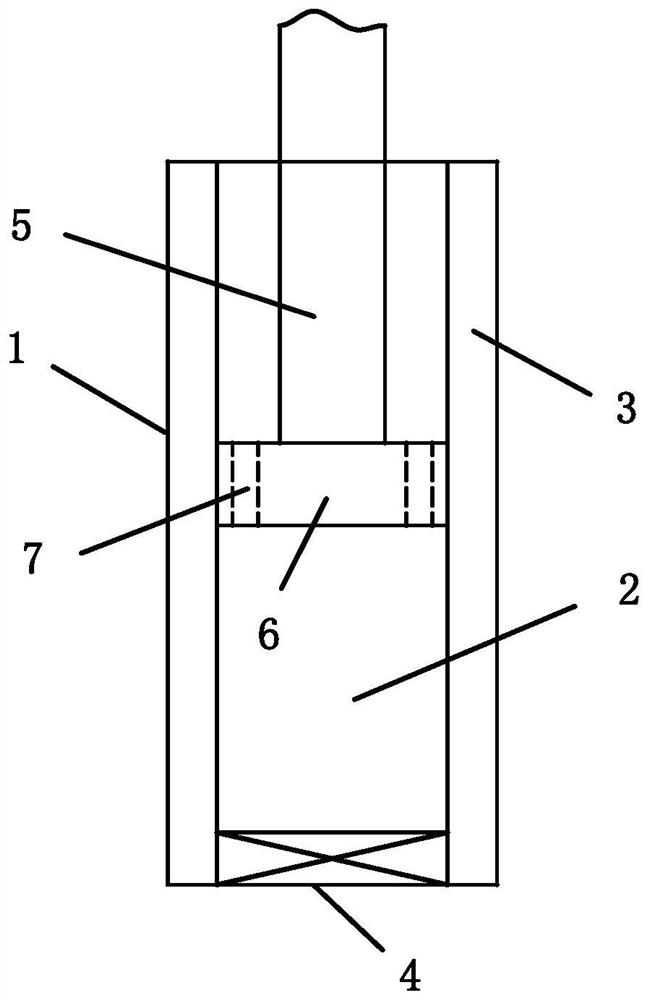

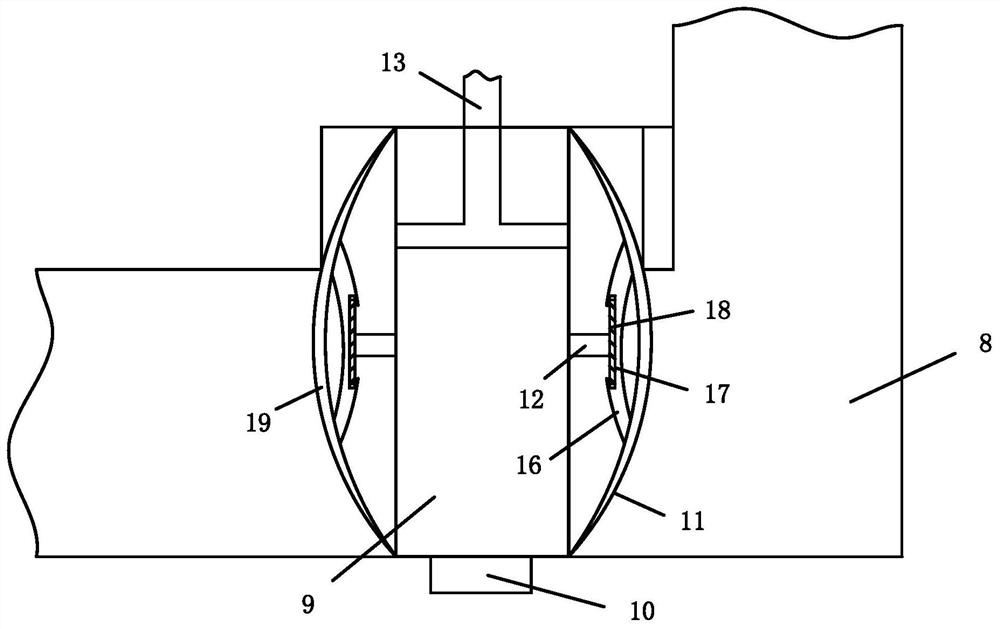

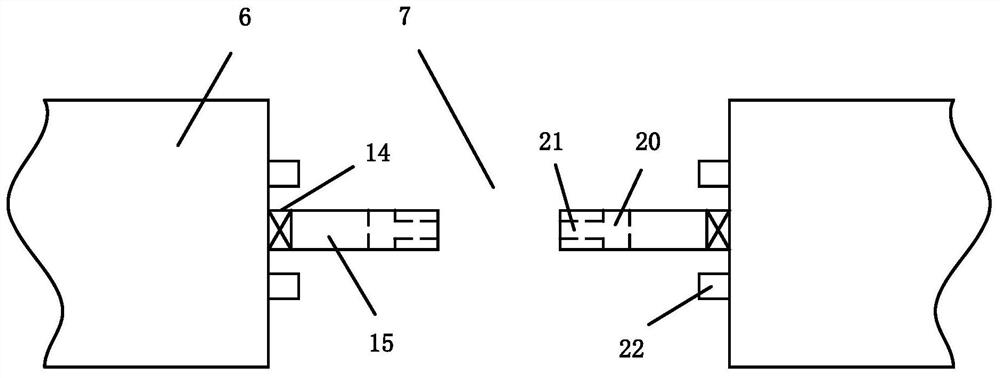

[0015] refer to Figure 1-3 , a specific embodiment of the present invention includes a cylinder 1, an oil chamber 2 is arranged inside the cylinder 1, an air chamber 3 is arranged between the oil chamber 2 and the outer wall of the cylinder 1, and the bottom of the oil chamber 2 is connected to the air chamber through a regulating valve 4 The 3 phases are connected, and the piston rod 5 is movably inserted in the oil chamber 2. The end of the piston rod 5 is fixed with a sealing plug 6 that is in sliding contact with the inner wall of the oil chamber 2. An oil hole 7 is opened on the sealing plug 6. The regulating valve 4 includes a valve body 8, a valve core 9 is installed in the valve body 8, the valve core 9 is connected with the servo motor 10, an air bag 11 is arranged on the outer edge of the valve core 9, a spring 12 is installed in the air bag 11, and the air bag 11 is connected with the intake and exhaust The tubes 13 are connected; the inner edge of the oil hole 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com