Concealed fluorescent anti-counterfeiting ink as well as preparation method and application thereof

An anti-counterfeiting ink, concealed technology, applied in the direction of ink, application, household appliances, etc., can solve the problem of low anti-counterfeiting level, achieve the effect of improving the anti-counterfeiting level and enhancing the difficulty of counterfeiting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In terms of mass percentage, dissolve 0.02g fluorescein in a mixed solvent of 3.0g ethanol, 1.88g isopropanol and 2g n-butanol, stir at room temperature for half an hour, then place it with 3.0g polyurethane resin and 0.1g wax powder Add an appropriate amount of glass beads for ink preparation to the ink sample preparation iron tank, seal the seal and disperse with a shaker at room temperature for half an hour, and filter the resulting solution with a 300-mesh screen to obtain a concealed fluorescent anti-counterfeiting ink.

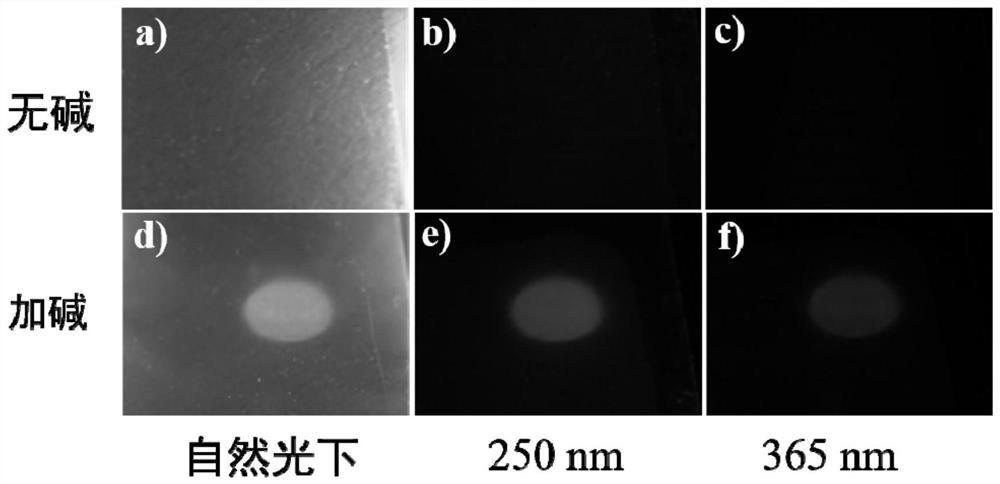

[0025] The obtained concealed fluorescent anti-counterfeiting ink is drawn on a transparent polyethylene plastic film, and a sample film is obtained after drying. figure 1 The sample film after drying is under the irradiation of a) natural light, b) ultraviolet light 250nm and c) ultraviolet light 365nm respectively, and the sample film after adding alkali is respectively irradiated by d) natural light, e) ultraviolet light 250nm and f) ultraviolet...

Embodiment 2

[0027] In terms of mass percentage, dissolve 0.01g of fluorescein in a mixed solvent of 2.0g of ethanol, 3.39g of isopropanol and 2g of n-butanol, stir at room temperature for half an hour, and place it with 2.5g of polyurethane resin and 0.1g of wax powder. Add an appropriate amount of glass beads for ink preparation to the ink sample preparation iron tank, seal the seal and disperse with a shaker at room temperature for half an hour, and filter the resulting solution with a 300-mesh screen to obtain a concealed fluorescent anti-counterfeiting ink. The obtained ink is drawn on a transparent polyethylene plastic film, and a sample film is obtained after drying.

[0028] The color development of the film obtained in this example before and after adding alkali is similar to Example 1 under natural light and ultraviolet light.

Embodiment 3

[0030] In terms of mass percentage, dissolve 0.02g fluorescein in a mixed solvent of 3.0g ethanol, 2.88g isopropanol and 2g n-butanol, stir at room temperature for half an hour, then place it with 2.0g polyurethane resin and 0.1g wax powder Add an appropriate amount of glass beads for ink preparation to the ink sample preparation iron tank, seal the seal and disperse with a shaker at room temperature for half an hour, and filter the resulting solution with a 300-mesh screen to obtain a concealed fluorescent anti-counterfeiting ink. The obtained ink is drawn on a transparent polyethylene plastic film, and a sample film is obtained after drying.

[0031] The color development of the film obtained in this example before and after adding alkali is similar to Example 1 under natural light and ultraviolet light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com