Antibacterial mildew-proof degradable plastic and preparation method thereof

A technology for degrading plastics, antibacterial and anti-mildew, applied in the field of plastic processing, can solve the problems of poor anti-bacterial and anti-mildew effect, inability to balance biodegradability and mechanical properties, etc., and achieve the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

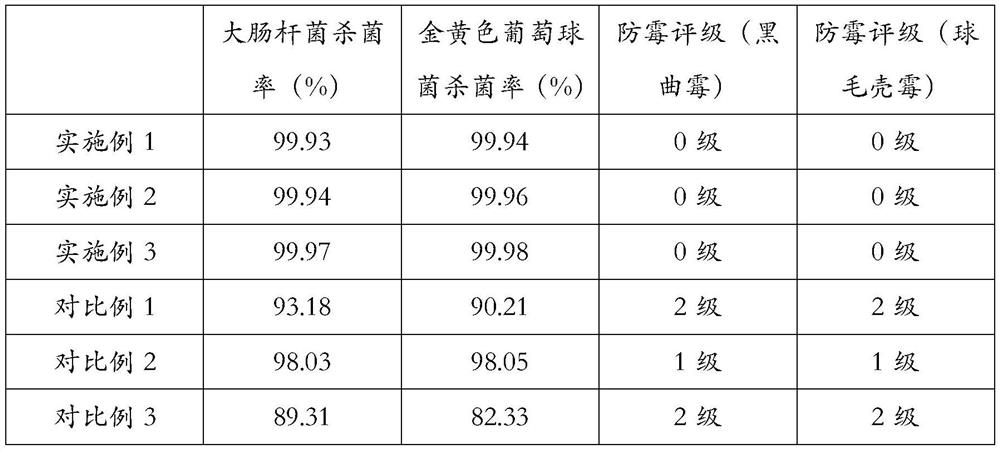

Examples

Embodiment 1

[0046] A preparation method of antibacterial and antifungal degradable plastics, first epoxidizing the dioxanone-ε-caprolactone copolymer to obtain an epoxidized product, and then decomposing the epoxidized product with modified nano fillers The modified polymer is obtained by ring reaction, and then the modified polymer and the modified collagen are mixed, melt-extruded and cast, and the post-treatment is to obtain the antibacterial and mildew-proof degradable plastic; wherein the modified nano filler It is prepared by the following method:

[0047] (A) Ammonium molybdate, selenium powder, and zinc powder are used as raw materials to make zinc-doped molybdenum selenide nanospheres through hydrothermal reaction;

[0048] (B) modifying the zinc-doped molybdenum selenide nanospheres with N-β-(aminoethyl)-γ-aminopropylmethyldimethoxysilane to obtain modified nanospheres;

[0049] (C) finally dissolving polyhexamethylene guanidine phosphate in water, then adding modified nanosphe...

Embodiment 2

[0069] A preparation method of antibacterial and antifungal degradable plastics, first epoxidizing the dioxanone-ε-caprolactone copolymer to obtain an epoxidized product, and then decomposing the epoxidized product with modified nano fillers The modified polymer is obtained by ring reaction, and then the modified polymer and the modified collagen are mixed, melt-extruded and cast, and the post-treatment is to obtain the antibacterial and mildew-proof degradable plastic; wherein the modified nano filler It is prepared by the following method:

[0070] (A) Ammonium molybdate, selenium powder, and zinc powder are used as raw materials to make zinc-doped molybdenum selenide nanospheres through hydrothermal reaction;

[0071] (B) modifying the zinc-doped molybdenum selenide nanospheres with N-β-(aminoethyl)-γ-aminopropylmethyldimethoxysilane to obtain modified nanospheres;

[0072] (C) finally dissolving polyhexamethylene guanidine phosphate in water, then adding modified nanosphe...

Embodiment 3

[0092] A preparation method of antibacterial and antifungal degradable plastics, first epoxidizing the dioxanone-ε-caprolactone copolymer to obtain an epoxidized product, and then decomposing the epoxidized product with modified nano fillers The modified polymer is obtained by ring reaction, and then the modified polymer and the modified collagen are mixed, melt-extruded and cast, and the post-treatment is to obtain the antibacterial and mildew-proof degradable plastic; wherein the modified nano filler It is prepared by the following method:

[0093] (A) Ammonium molybdate, selenium powder, and zinc powder are used as raw materials to make zinc-doped molybdenum selenide nanospheres through hydrothermal reaction;

[0094] (B) modifying the zinc-doped molybdenum selenide nanospheres with N-β-(aminoethyl)-γ-aminopropylmethyldimethoxysilane to obtain modified nanospheres;

[0095] (C) finally dissolving polyhexamethylene guanidine phosphate in water, then adding modified nanosphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com