PP flame-retardant plastic

A technology of flame-retardant plastics and flame retardants, which is applied in the field of PP flame-retardant plastics, can solve the problems of self-performance degradation, poor flame retardancy, and poor cold resistance of PP plastics, and achieve the effect of improving oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

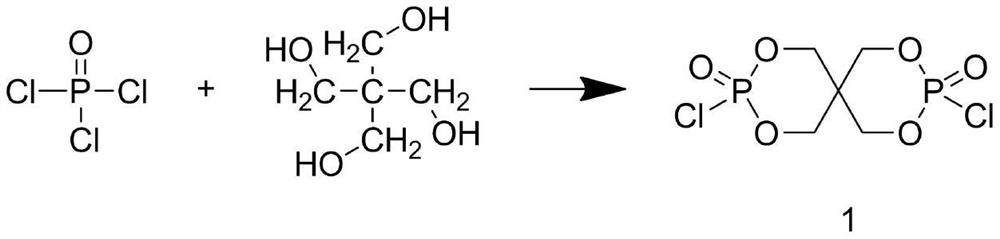

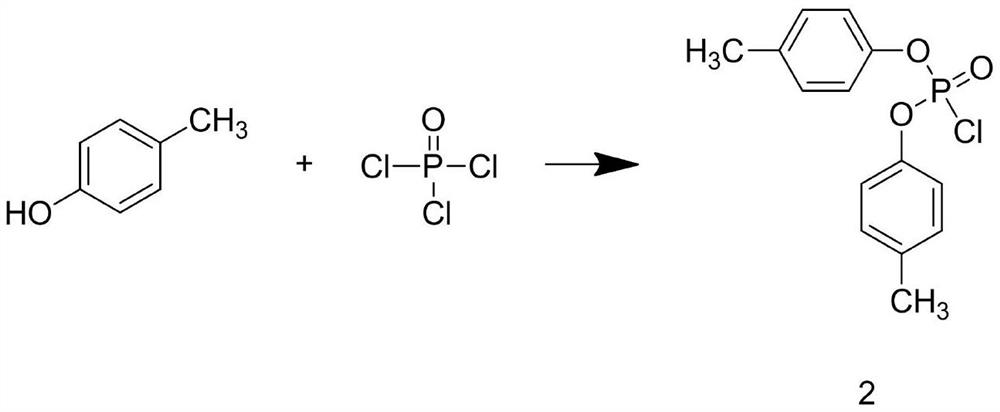

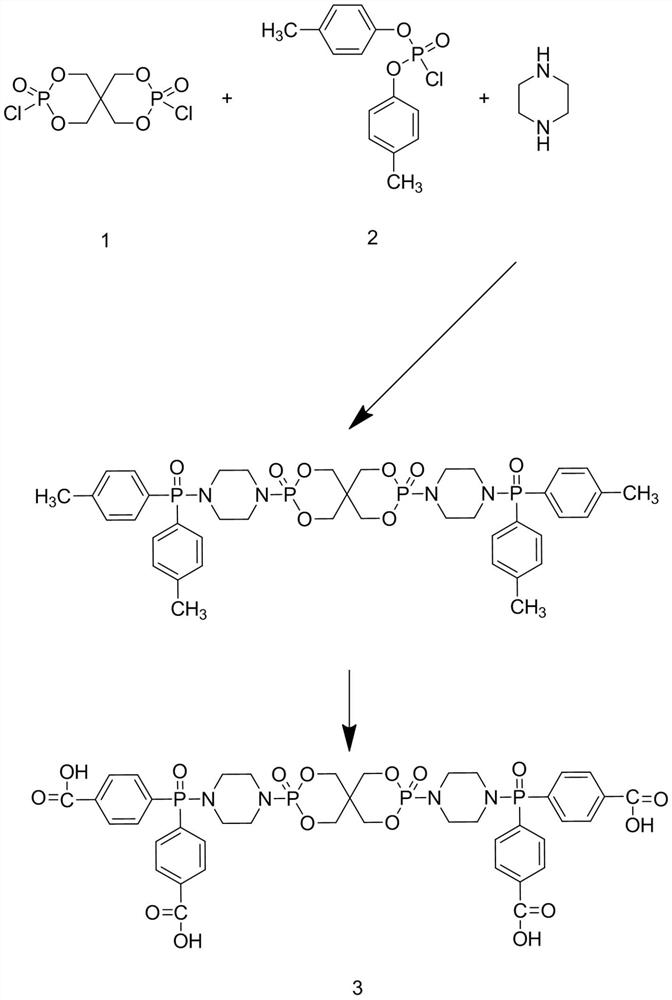

Method used

Image

Examples

Embodiment 1

[0038] A PP flame-retardant plastic, made of the following raw materials in parts by weight: 80 parts of polypropylene, 2 parts of flame retardant, 3 parts of liquid paraffin, 3 parts of plasticizer, and 3 parts of phenyl o-hydroxybenzoate;

[0039] The PP flame retardant plastic is made by the following steps:

[0040] Step S1: stirring the polypropylene and liquid paraffin for 10 min at a rotational speed of 300 r / min to obtain a first mixture;

[0041] Step S2: Stir the flame retardant and phenyl o-hydroxybenzoate for 3 minutes at a rotational speed of 500 r / min, add a plasticizer, and continue stirring for 10 minutes to obtain the secondary mixture;

[0042]Step S3: melting and stirring the first mixed material and the second mixed material for 30 minutes at a rotation speed of 1000 r / min and a temperature of 160° C. to obtain a molten material;

[0043] Step S4: Put the molten material into a three-stage twin-screw extruder, extrude and cool and pelletize under the condi...

Embodiment 2

[0053] A PP flame-retardant plastic, made of the following raw materials in parts by weight: 85 parts of polypropylene, 3 parts of flame retardant, 4 parts of liquid paraffin, 4 parts of plasticizer, and 4 parts of phenyl o-hydroxybenzoate;

[0054] The PP flame retardant plastic is made by the following steps:

[0055] Step S1: Stir the polypropylene and liquid paraffin for 13 minutes at a rotational speed of 400 r / min to obtain a first mixture;

[0056] Step S2: Stir the flame retardant and phenyl o-hydroxybenzoate for 4 minutes at a rotational speed of 600 r / min, add a plasticizer, and continue stirring for 13 minutes to obtain the secondary mixture;

[0057] Step S3: melting and stirring the first mixed material and the second mixed material for 35 minutes at a rotation speed of 1100 r / min and a temperature of 170° C. to obtain a molten material;

[0058] Step S4: Put the molten material into a three-stage twin-screw extruder, extrude and cool and pelletize under the cond...

Embodiment 3

[0068] A PP flame-retardant plastic, made of the following raw materials in parts by weight: 90 parts of polypropylene, 4 parts of flame retardant, 4 parts of liquid paraffin, 4 parts of plasticizer, and 4 parts of phenyl o-hydroxybenzoate;

[0069] The PP flame retardant plastic is made by the following steps:

[0070] Step S1: stirring the polypropylene and liquid paraffin for 15 minutes at a rotational speed of 400 r / min to obtain a first mixture;

[0071] Step S2: Stir the flame retardant and phenyl o-hydroxybenzoate for 4 minutes at a rotational speed of 700 r / min, add a plasticizer, and continue stirring for 15 minutes to obtain a secondary mixture;

[0072] Step S3: melting and stirring the first mixture and the second mixture for 30-40 minutes under the conditions of a rotating speed of 1000-1200 r / min and a temperature of 160-180° C. to obtain a molten material;

[0073] Step S4: Put the molten material into a three-stage twin-screw extruder, extrude and cool and pel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com