Structural material

A technology for structural materials and raw materials, which is applied in the field of resource utilization of solid pollutants, can solve the problem of high operating costs, and achieve the effects of reducing operating costs, ensuring environmental friendliness, and eliminating peculiar smells.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

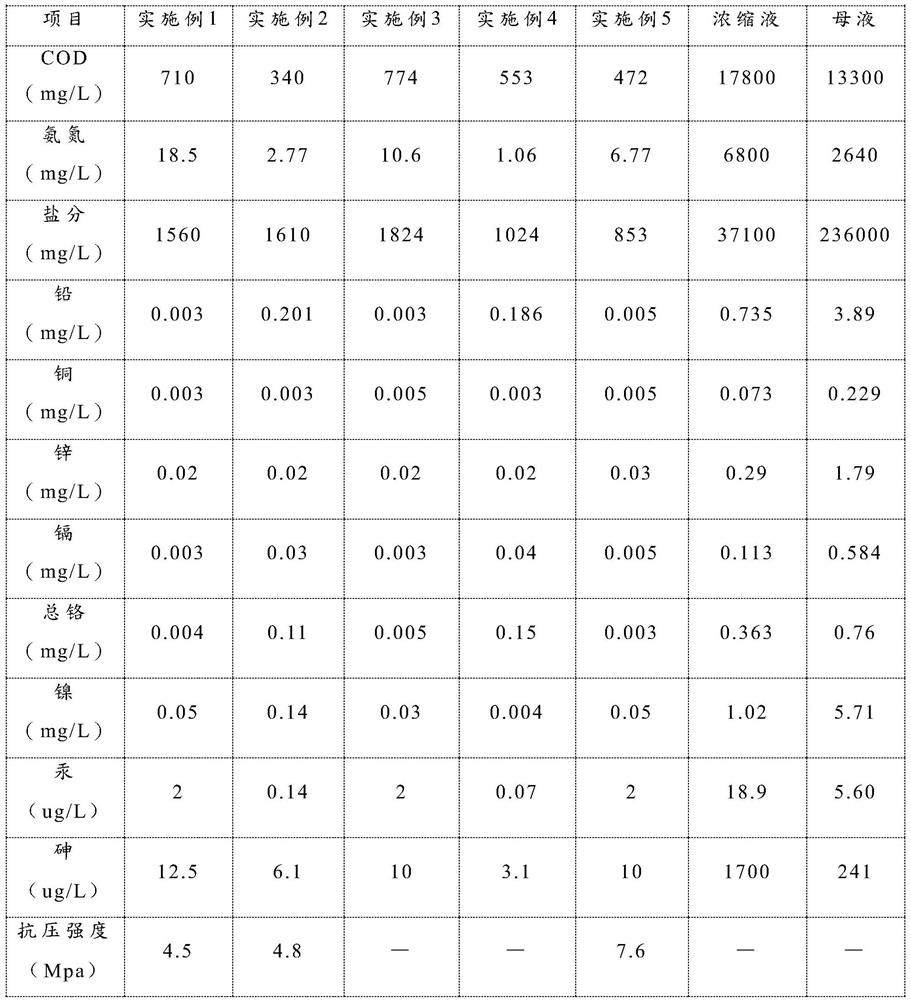

Embodiment 1

[0034] A method for synergistically preparing garbage covering soil with fly ash and concentrated solution, the process comprises the following steps:

[0035] Put 70 parts of fly ash, 20 parts of bentonite, 10 parts of Portland cement, 0.5 parts of carboxymethyl cellulose, and 150 parts of concentrate into a special mixing and stirring equipment, mix evenly and vigorously stir for 10 minutes, and the obtained slurry The cured material is sprayed onto the surface of the garbage dump by special spraying equipment, and the thickness of a single spray is 30mm. After drying and curing are completed within 24 hours, it is sprayed again to cover, and this cycle is repeated 3 times to form a stable garbage covering layer.

Embodiment 2

[0037] A method for synergistically preparing garbage covering soil from fly ash and the mother liquor of the concentrated solution, the process comprises the following steps:

[0038]Put 60 parts of fly ash, 20 parts of bentonite, 20 parts of Portland cement, 1 part of carboxymethyl cellulose, 5 parts of zeolite powder, and 80 parts of concentrated liquid into the special mixing and stirring equipment, mix evenly and vigorously In 10 minutes, the obtained slurry solidified material is sprayed onto the surface of the garbage dump through a special spraying equipment, and the thickness of a single spray is 30mm. After drying and curing are completed within 48 hours, it is sprayed again to cover, and this cycle is repeated 4 times to form a stable garbage cover. Floor.

Embodiment 3

[0040] A kind of method that fly ash and concentrated solution synergistically prepare cushion soil, the process comprises the following steps:

[0041] Put 70 parts of fly ash, 15 parts of bentonite, 10 parts of Portland cement, 1 part of carboxymethyl cellulose, 0.2 parts of sodium carbonate, 0.2 parts of water glass, and 70 parts of concentrate into a special mixing and stirring equipment, and mix evenly And vigorously stir for 10min, this slurry is more viscous, carry out drying by dryer, drying time is 6h, until water content is 40wt%, carry out granulation by special granulation equipment, granulation particle diameter can be controlled in Between 2mm and 10mm, the moisture content of the whole granulation process is further reduced to below 35wt%, and the moisture content will be further reduced after natural storage, and it is ready for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com