Nickel-cobalt-manganese net-shaped structure precursor, nickel-cobalt-manganese composite oxide powder as well as preparation method and application thereof

A technology of composite hydroxide and network structure, which is applied in the field of materials, can solve the problems that the power performance of materials cannot be effectively exerted, and the efficiency of first charge and discharge is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

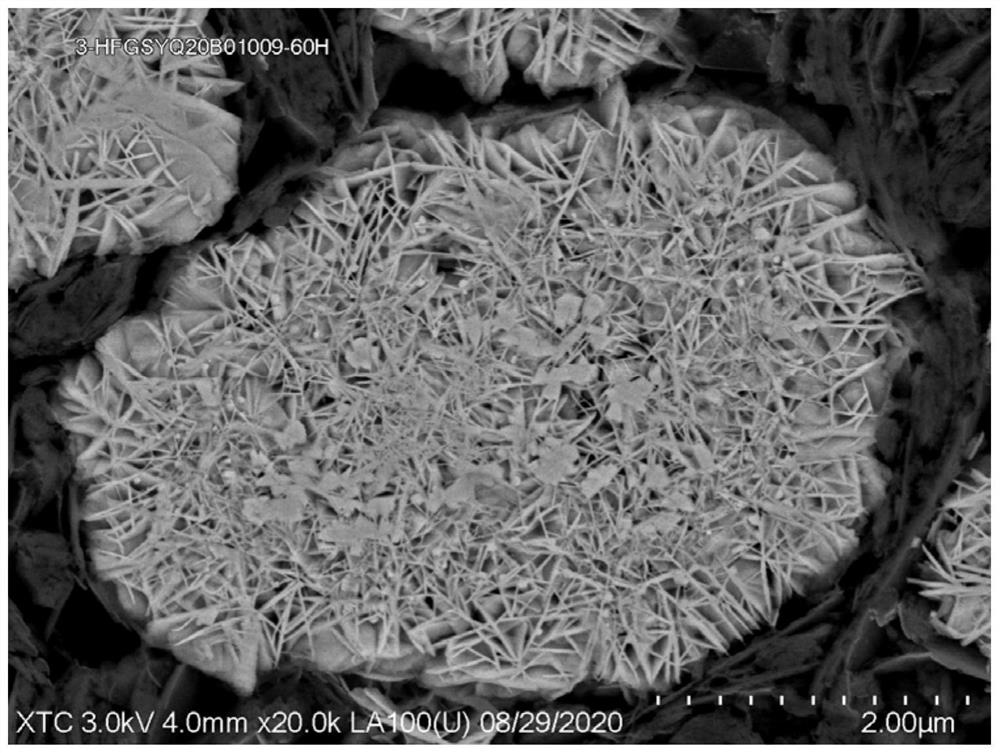

Image

Examples

Embodiment 1

[0040] S1. Add nickel-cobalt-manganese composite metal (the molar ratio of Ni, Co, and Mn is 1:1:1), elemental zirconium, nitric acid, high-purity water, and sodium sulfate at the same time according to the molar ratio of 10:0.003:1:1:1 To the reactor, add 2g / L ammonium sulfate at the same time, under normal pressure conditions, control the ORP value at -100mv, control the concentration of complexing agent at 3g / L, control the conductivity at 200uS / cm, stir The input power is controlled at 1kw / m 3 h. The concentration of metal ions is controlled at 5g / L, the pH value is controlled at 6-8, and the temperature is controlled at 20°C to carry out chemical corrosion precipitation reaction to form a loose inner core, and the growth rate of precipitated particles during the chemical corrosion precipitation reaction process (Detected by a laser particle size analyzer, the same below) is 2μm / 10h. Water is continuously consumed during the reaction and no excess waste water is produced. ...

Embodiment 2

[0045] S1. Combine nickel-cobalt-manganese composite metal oxide (the molar ratio of NiO, CoO, and MnO is 5:2:3), tungsten oxide, nitric acid, high-purity water, and sodium chloride according to the molar ratio of 10:0.03:1:1:1. The flow is added to the reactor at the same time, and 7g / L of ethylenediaminetetraacetic acid is added at the same time. Under normal pressure conditions, the ORP value of the oxidation-reduction potential is controlled at 100mv, the concentration of the complexing agent is controlled at 8g / L, and the conductivity is controlled at 500uS / cm, stirring input power controlled at 0.7kw / m 3 h. The metal ion concentration is controlled at 5g / L, the pH value is controlled at 8-10, and the temperature is controlled at 60°C to carry out chemical corrosion precipitation reaction to form a loose inner core, and the growth rate of precipitated particles during the chemical corrosion precipitation reaction process It is 2.8μm / 10h, water is consumed continuously dur...

Embodiment 3

[0050]S1. Combine nickel-cobalt-manganese composite metal (the molar ratio of Ni, Co, and Mn is 6:2:2), elemental tungsten, oxygen, high-purity water, and sodium chloride in parallel at the same time according to the molar ratio of 10:0.003:1:1:4 Add it into the reactor and add 4g / L ammonium nitrate at the same time. Under normal pressure, control the ORP value at 0mv, the conductivity at 1000uS / cm, and the stirring input power at 0.1kw / m 3 h. The metal ion concentration is controlled at 5g / L, the pH value is controlled at 10-11, and the temperature is controlled at 90°C to carry out chemical corrosion precipitation reaction to form a loose inner core, and the growth rate of precipitated particles during the chemical corrosion precipitation reaction process It is 3.2μm / 10h, water is consumed continuously during the reaction process, and no excess waste water is produced. After 30 hours of reaction, the precipitation cycle reaches 50%. Oxygen is introduced at a rate of 8L / h and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Hole size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com