Cobalt and nitrogen doped carbon nanotube as well as preparation method and application thereof

A nitrogen-doped carbon and nanotube technology, applied in carbon nanotubes, nanocarbons, chemical instruments and methods, etc., can solve the problems of increasing material cost, cumbersome process and processing steps, hindering large-scale synthesis of catalysts, etc. The effect of complete structure, good morphology and simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

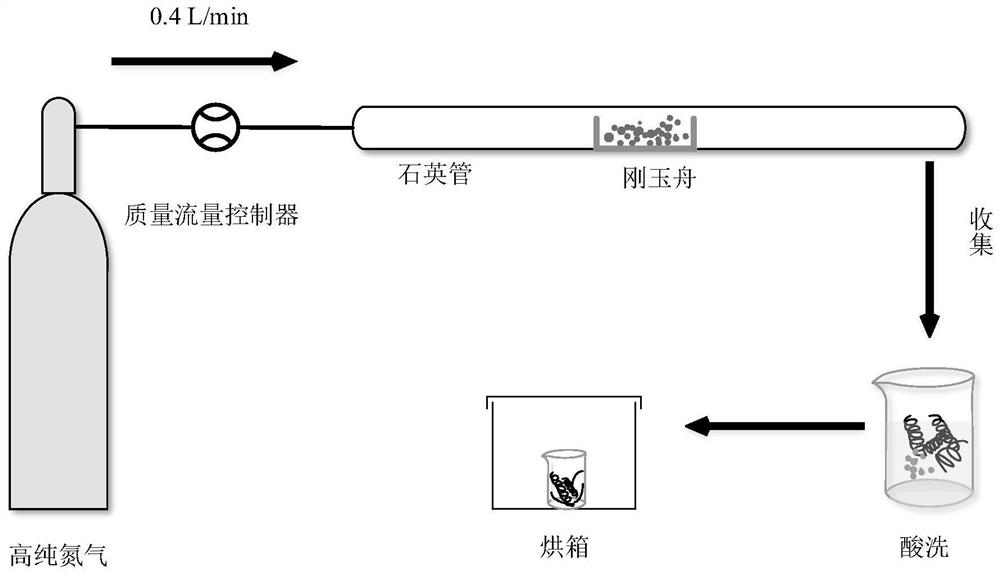

[0026] Step 1, weigh 1.5g of cobalt acetate and disperse in 30ml of ethanol solution, stir and dissolve at 80°C, add 3.5g of dicyandiamide after dissolution, continue to stir, evaporate the solvent for 6h, transfer the above mixture to a beaker, and store at room temperature Evaporate the remaining solvent in a magnetic stirring device, stir overnight, and dry at 80°C to obtain a powdery precursor;

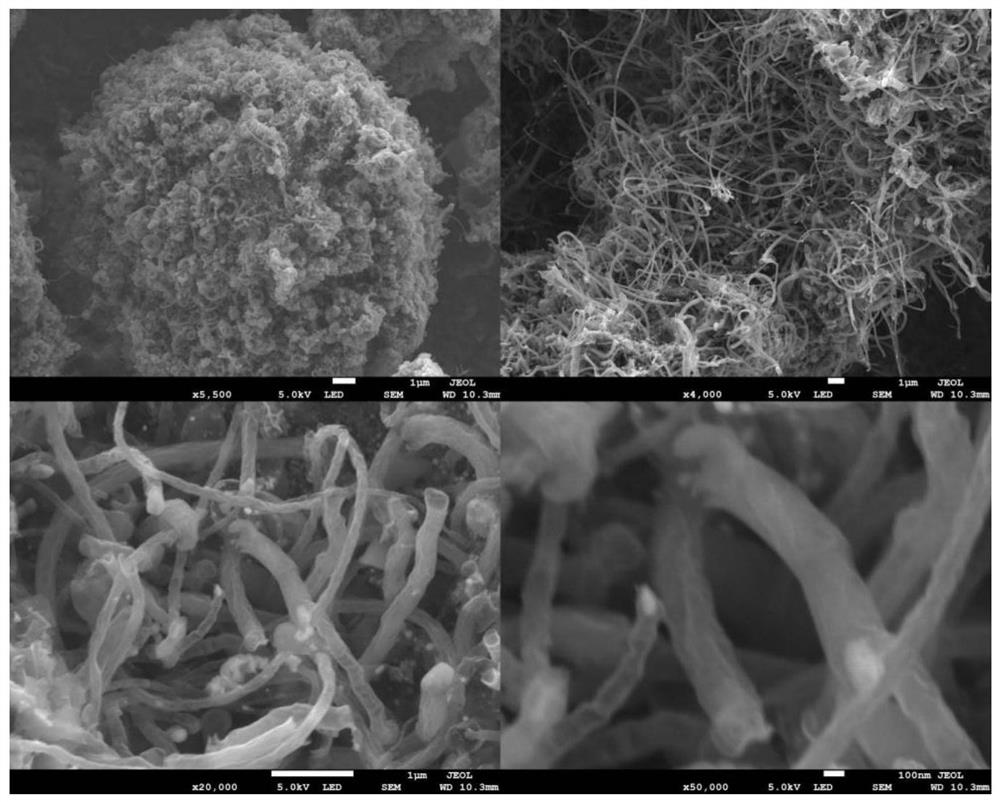

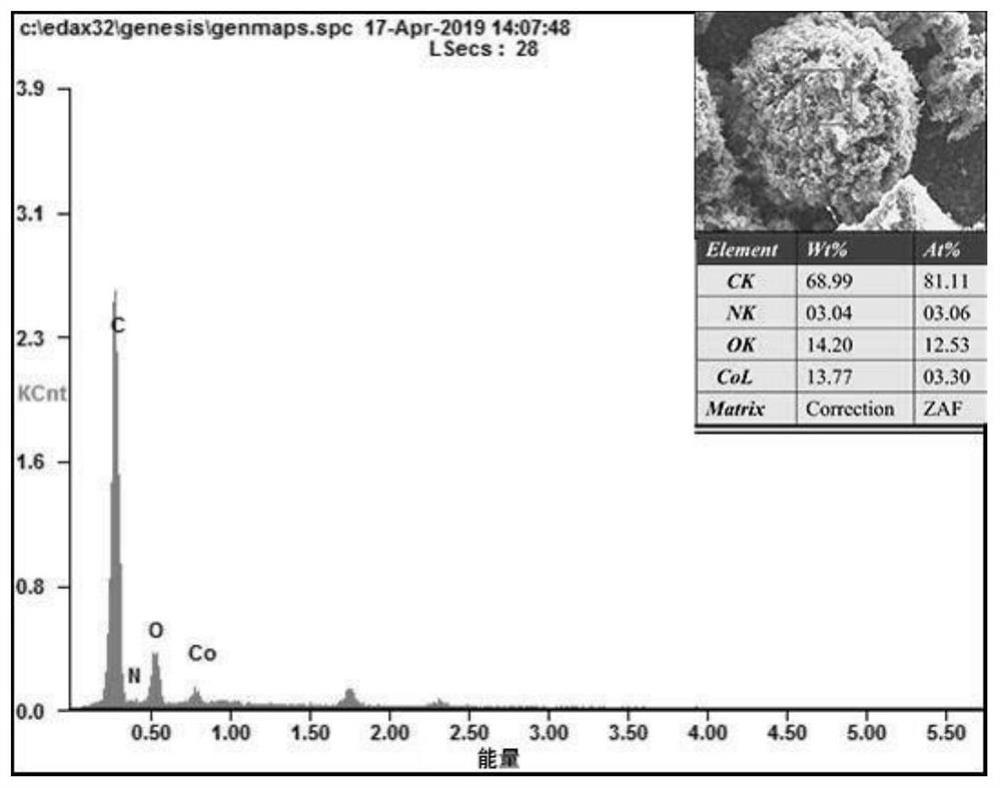

[0027] Step 2, the powdery precursor obtained after drying is ground in an agate mortar for 5 minutes and then transferred to a corundum boat. The temperature of the tube furnace is raised to 750°C, and the heating rate of calcination is 10°C / min. Before reaching the set temperature, the sample It needs to be placed in the non-heating area of the quartz tube. After reaching the set temperature, the sample is pushed into the tube-type heating furnace and calcined for 1 hour. The whole process is under N 2 Atmosphere, flow rate 0.4L / min, after the calcination is completed, anneal ...

Embodiment 2

[0030] Step 1, weigh 1.5g of cobalt acetate and disperse in 30ml of ethanol solution, stir and dissolve at 70°C, add 3.0g of dicyandiamide after dissolution, continue to stir, evaporate the solvent for 6h, transfer the above mixture to a beaker, and store at room temperature Evaporate the remaining solvent in a magnetic stirring device, stir overnight, and dry at 70°C to obtain a powdery precursor;

[0031] Step 2, the powdery precursor obtained after drying was ground in an agate mortar for 3 minutes and then transferred to a corundum boat. The temperature of the tube furnace was raised to 900°C, and the heating rate of the calcination was 8°C / min. Before reaching the set temperature, the sample It needs to be placed in the non-heating area of the quartz tube. After reaching the set temperature, the sample is pushed into the tubular heating furnace. The sample is put in and calcined for 2 hours. The whole process is under N 2 Atmosphere, flow rate 0.3L / min, after the calcin...

Embodiment 3

[0034] Step 1, weigh 2.0g of cobalt acetate tetrahydrate and disperse in 30ml of ethanol solution, stir and dissolve at 80°C, add 3.0g of dicyandiamide after dissolution, continue to stir, evaporate the solvent for 6h, transfer the above mixture to a beaker, and Evaporate the remaining solvent in a magnetic stirring device at room temperature, stir overnight, and dry at 80°C to obtain a powdery precursor;

[0035] Step 2, the powdery precursor obtained after drying is ground in an agate mortar for 5 minutes and then transferred to a corundum boat. The temperature of the tube furnace is raised to 1000°C, and the heating rate of calcination is 12°C / min. Before reaching the set temperature, the sample It needs to be placed in the non-heating area of the quartz tube. After reaching the set temperature, the sample is pushed into the tube-type heating furnace and calcined for 0.5h. The whole process is under N 2 Atmosphere, flow rate 0.4L / min, after the calcination is completed, ann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com