Regeneration method of waste concrete and modified recycled concrete

A technology for waste concrete and recycled concrete, applied in the field of concrete, can solve the problems of unpredictable concrete recovery effect, inability to reuse waste gas concrete, and increase in additional cost of recovery, so as to improve the added value of preparation and ensure the recycling rate. , the effect of improving the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

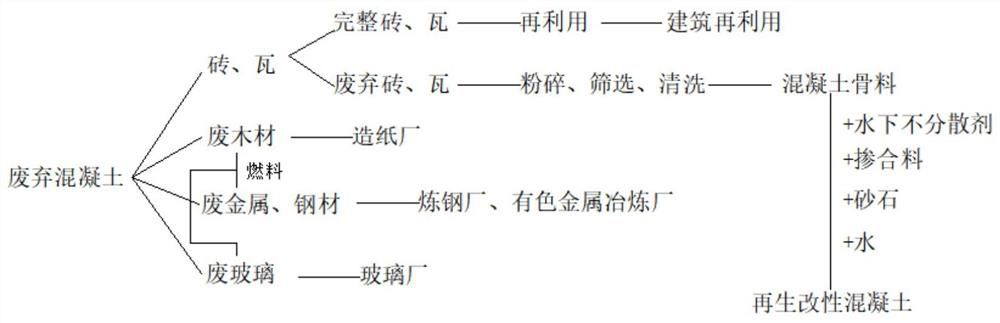

Method used

Image

Examples

Embodiment 1

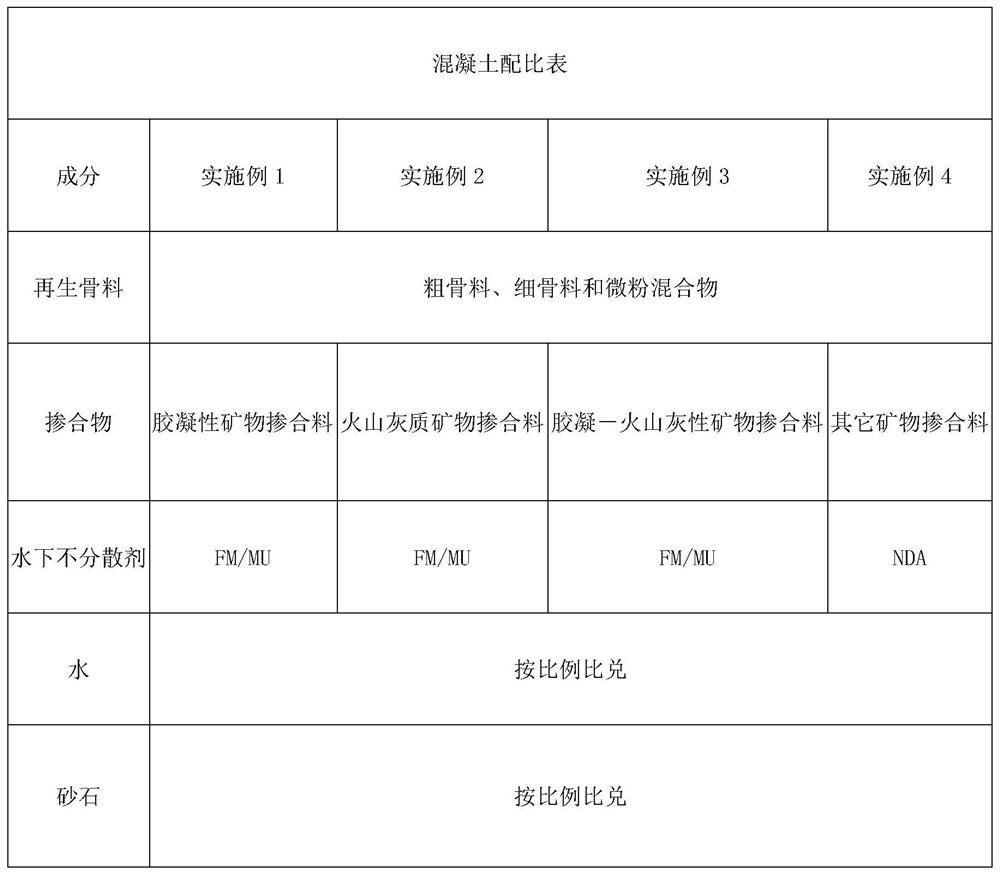

[0027] In this example, a modified recycled concrete, including recycled aggregate, admixture, underwater non-dispersible agent, water and sand, recycled aggregate, admixture, underwater non-dispersible agent, water and sand The ratio between them is 4.5:3.4:1.1:0.2:0.8, and the recycled aggregate includes recycled coarse aggregate, recycled fine aggregate and fine powder.

[0028] The admixture is a gelling mineral admixture, wherein the gelling mineral admixture includes at least one admixture of slag, high-calcium ash and sulfur-fixing slag, and the underwater non-dispersant is the underwater non-dispersant FM Or underwater non-dispersible agent UM.

Embodiment 2

[0030] In this example, a modified recycled concrete, including recycled aggregate, admixture, underwater non-dispersible agent, water and sand, recycled aggregate, admixture, underwater non-dispersible agent, water and sand The ratio between them is 4.4:3.5:1.1:0.2:0.8, and the recycled aggregate includes recycled coarse aggregate, recycled fine aggregate and fine powder.

[0031] The admixture is a pozzolanic mineral admixture, the pozzolanic mineral admixture is at least one admixture of volcanic ash, fly ash, silica fume and diatomaceous earth, and the underwater non-dispersant is an underwater non-dispersant FM Or underwater non-dispersant UM.

Embodiment 3

[0033] In this example, a modified recycled concrete, including recycled aggregate, admixture, underwater non-dispersible agent, water and sand, recycled aggregate, admixture, underwater non-dispersible agent, water and sand The ratio between them is 4.3:3.6:1.1:0.2:0.8, and the recycled aggregate includes recycled coarse aggregate, recycled fine aggregate and fine powder.

[0034] The admixture is a gelling-volcanic ash mineral admixture, the gelling-volcanic ash mineral admixture is a mixture of volcanic ash, granulated blast furnace coal ash, mineral admixture and industrial waste slag fine powder, and the underwater non-dispersant is water Underwater non-dispersant FM or underwater non-dispersant UM.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com