Pigment preparation device for drawing oil paintings

A technology for pigments and oil paintings, which is applied to the field of pigment preparation devices for painting oil paintings, can solve the problems of affecting the quality of pigment preparation, heavy labor for operators, and difficulty in achieving accurate cutting, and achieves simple structure, low use cost, and improved efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

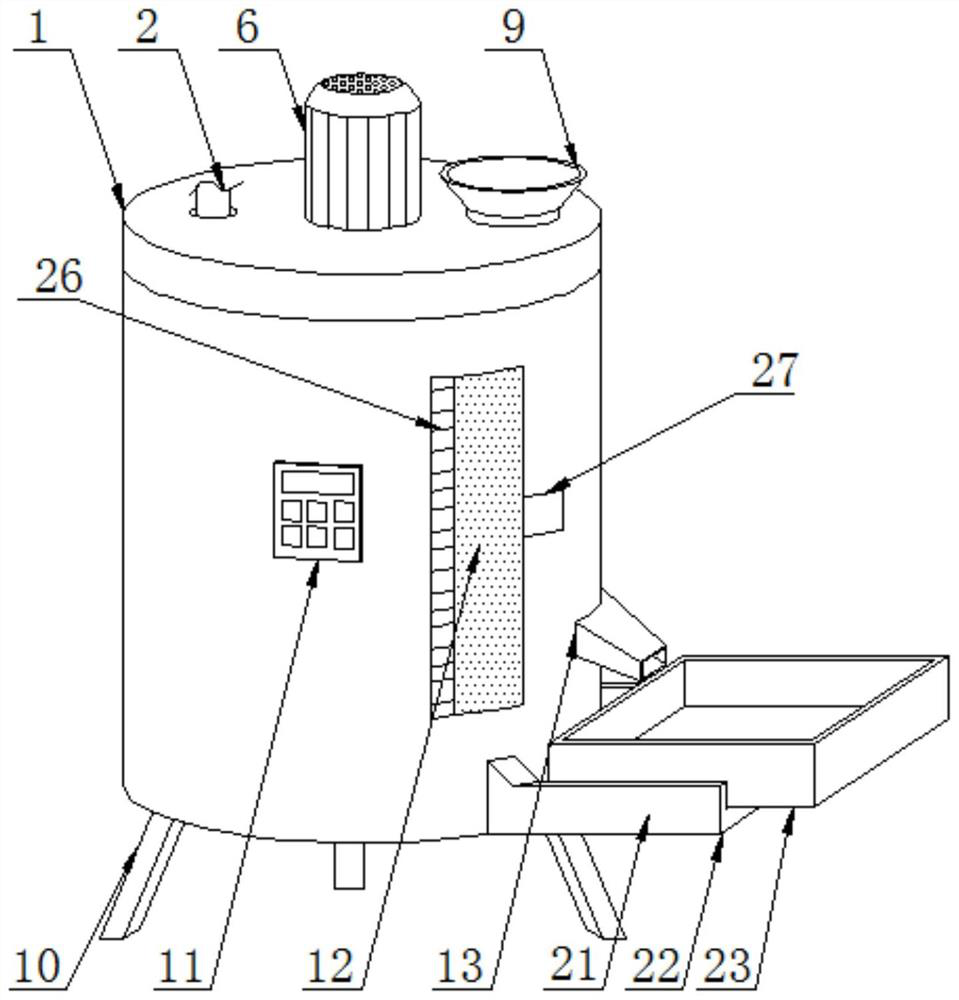

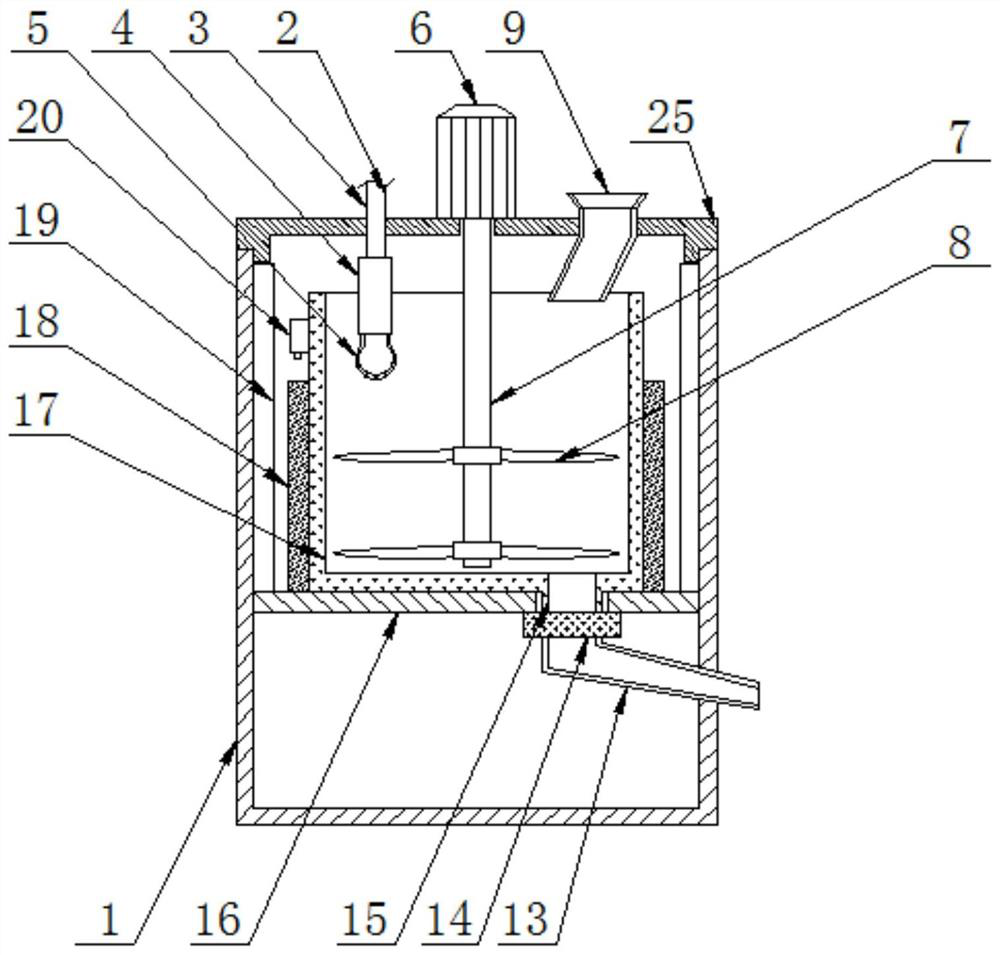

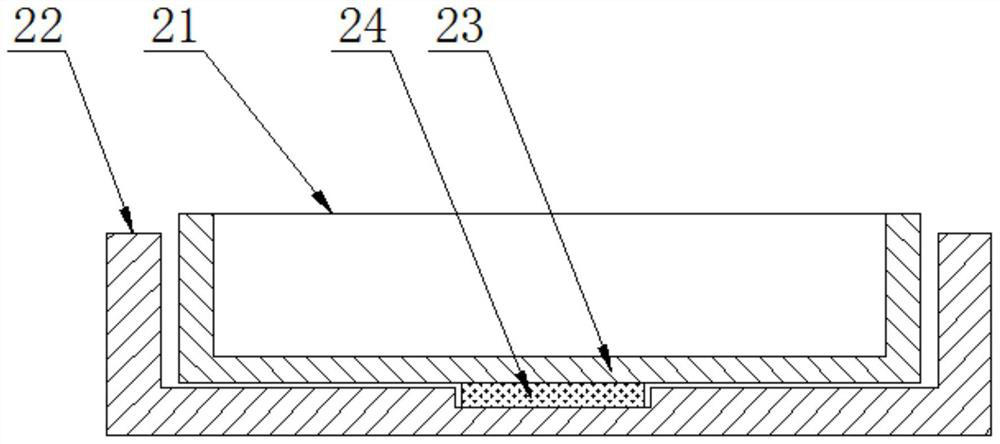

[0025] see Figure 1~4 , in an embodiment of the present invention, a pigment preparation device for drawing oil painting, comprising a body 1, a stirring assembly, a fine ingredient adding assembly, a cleaning assembly 2, a control panel 11, a viewing window 12, a color comparison bar 26 and a color matching display panel 27, Wherein, the body 1 is provided with a stirring assembly installed on the machine cover 25, and the machine cover 25 is detachably fastened to the through hole at the upper end of the body 1. It is characterized in that the fine ingredient adding assembly It is integrated with the cleaning assembly and protrudes into the body 1. A control panel 11 is installed on the front surface of the body 1. A vertically extending A visible window 12, one side of the visible window 12 is provided with the color comparison bar 26, and the other side of the visible window 12 is provided with a color matching display panel 27, and the color to be prepared can be control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com