Autoclaved curing furnace for autoclaved aerated concrete plates

A technology of autoclaved curing and autoclaved aeration, which is applied in the direction of furnaces, furnace components, lighting and heating equipment, etc. It can solve the problems of uneven curing of covered plates and low efficiency of plate curing, so as to avoid uneven steaming, Uniform effect of steaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

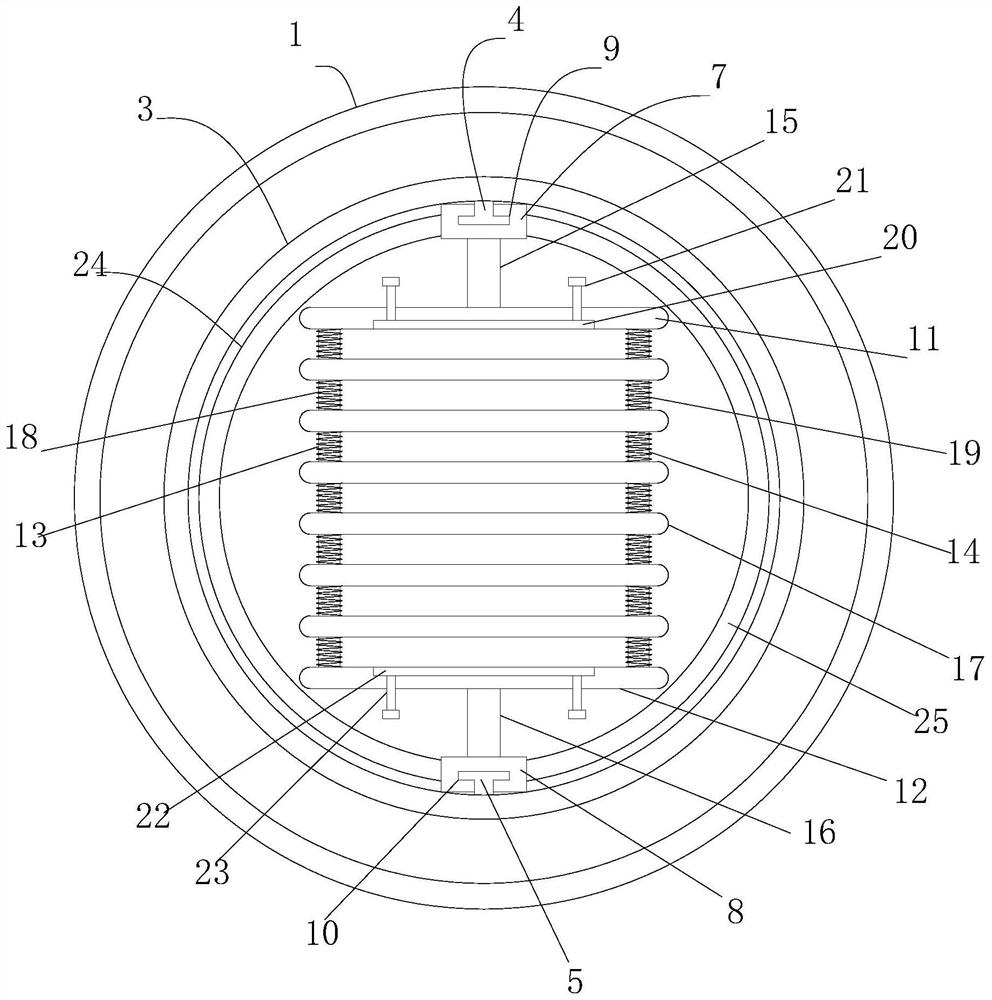

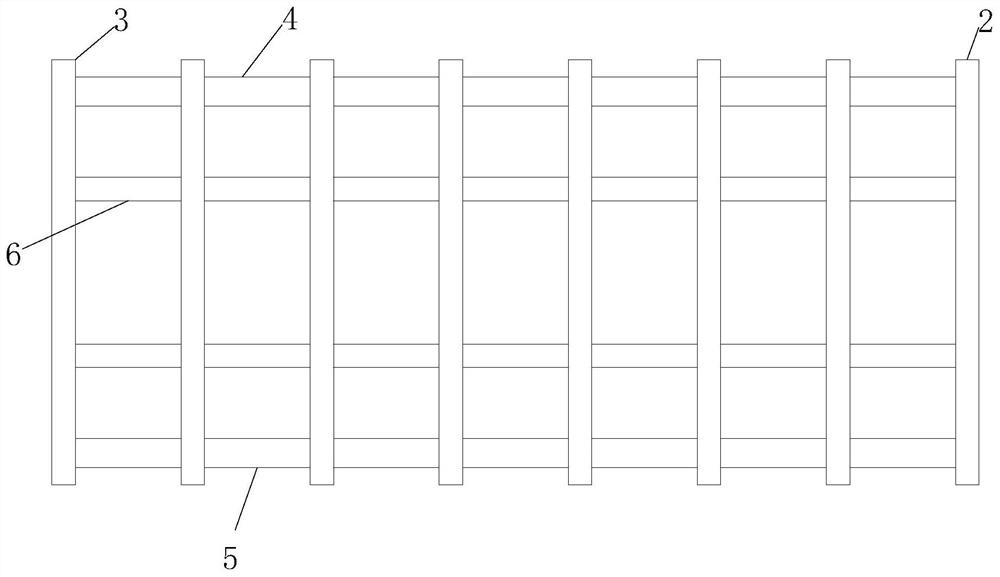

[0018] refer to figure 1 , figure 2 , the present invention proposes an autoclaved aerated concrete slab autoclaved curing furnace, comprising a furnace body 1, a turret, a driving member and a rack; wherein:

[0019] One end of the furnace body 1 is provided with a feed port, and a furnace cover is installed at the feed port. The turret is arranged in the furnace body 1 and installed on the furnace body 1 through the rotation of the rotating shaft. The inside of the turret is hollow and the end of the turret near the feed port is provided with a mounting port. The object frame is inserted into the interior of the turntable through the installation port, the object frame is connected with the turntable and can rotate with the rotation of the turntable; the driving part is connected with the turntable and drives the turntable to rotate.

[0020] The invention drives the turret to rotate through the driving part, and the turret drives the animal rack to rotate, so that the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com