Bulging die and method capable of retracting bulging petals at high temperature

A technology of bulging and bulging, which is applied in the field of bulging molds with retractable bulging at high temperature, can solve problems such as failure to work normally, failure to use, spring annealing failure, etc., to solve the problems that cannot be applied in engineering and realize continuous production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better explain the present invention and facilitate understanding, the technical solutions and effects of the present invention will be described in detail below through specific implementation manners in conjunction with the accompanying drawings.

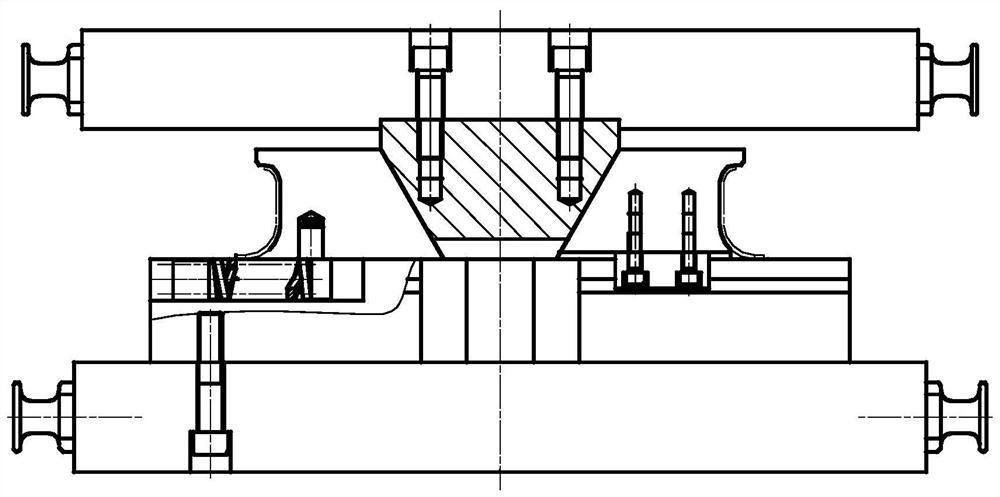

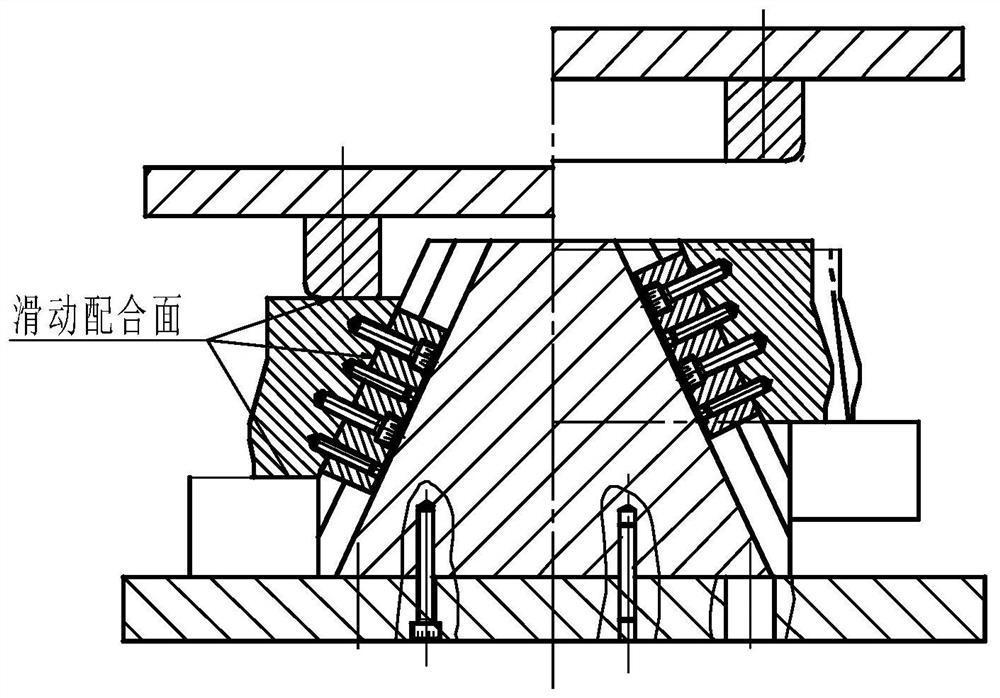

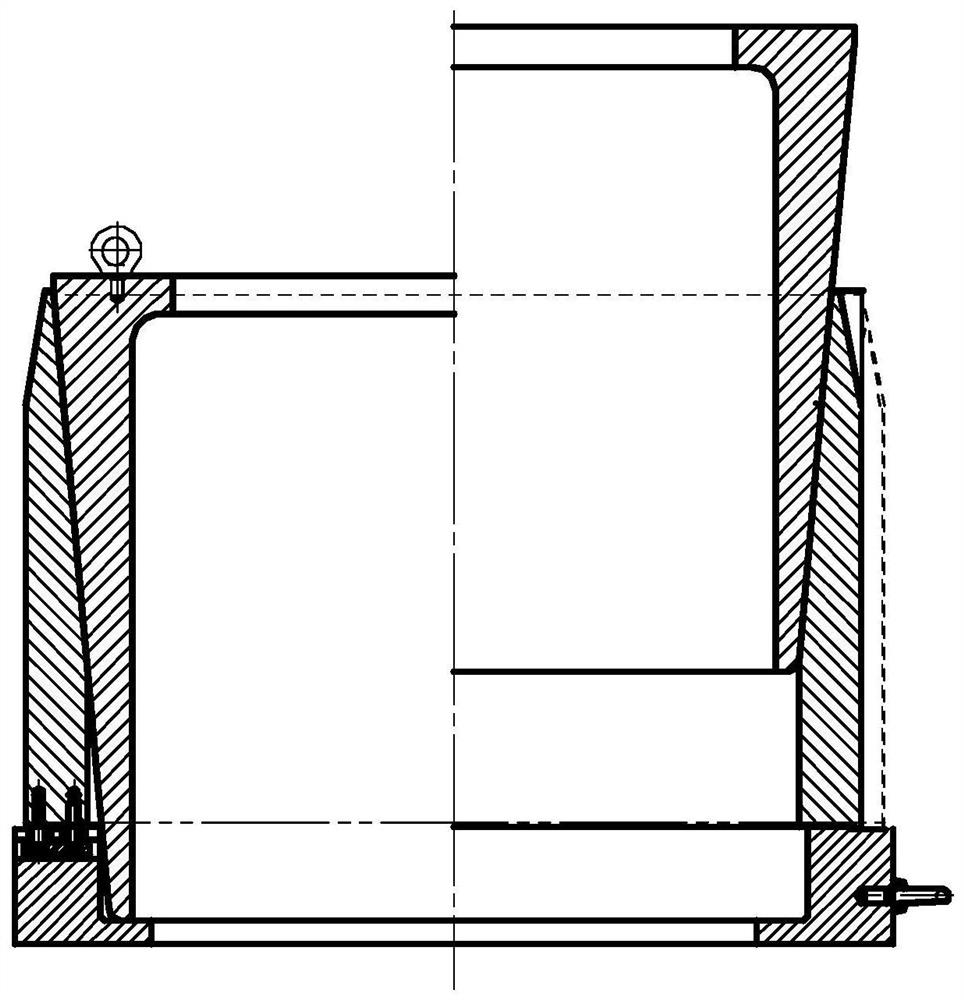

[0029] Such as Figure 4-5 As shown, a bulging mold with retractable bulging valve 9 at high temperature includes a lower template 1, and the upper surface of the lower template 1 is coaxially provided with two notches, and the inner support ring 14 and the outer support ring 4 are passed through bolts. It is connected with the lower template 1 and installed in the spigot, the inner support ring 14 is installed inside the outer support ring 4, and the two notches are used to ensure that the inner support ring 14 and the outer support ring 4 are coaxial; the lower template 1 is used for thermoforming equipment The milling platform connects and installs and fixes the inner support ring 14 and the outer support rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com