Spore physical wall breaking device and method based on laser light energy

A physical and light energy technology, applied in the direction of grain processing, etc., can solve the problems of large one-time investment, high production cost, and the difficulty of spore products becoming the mainstream of spore breaking, and achieve the effect of high degree of automation and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

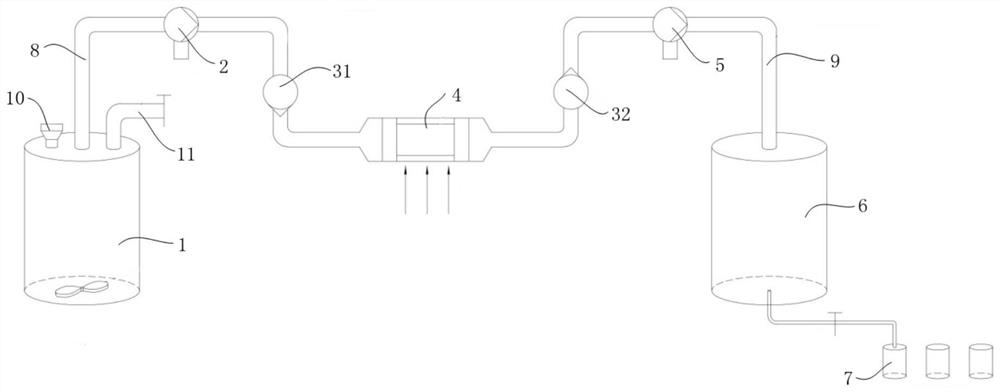

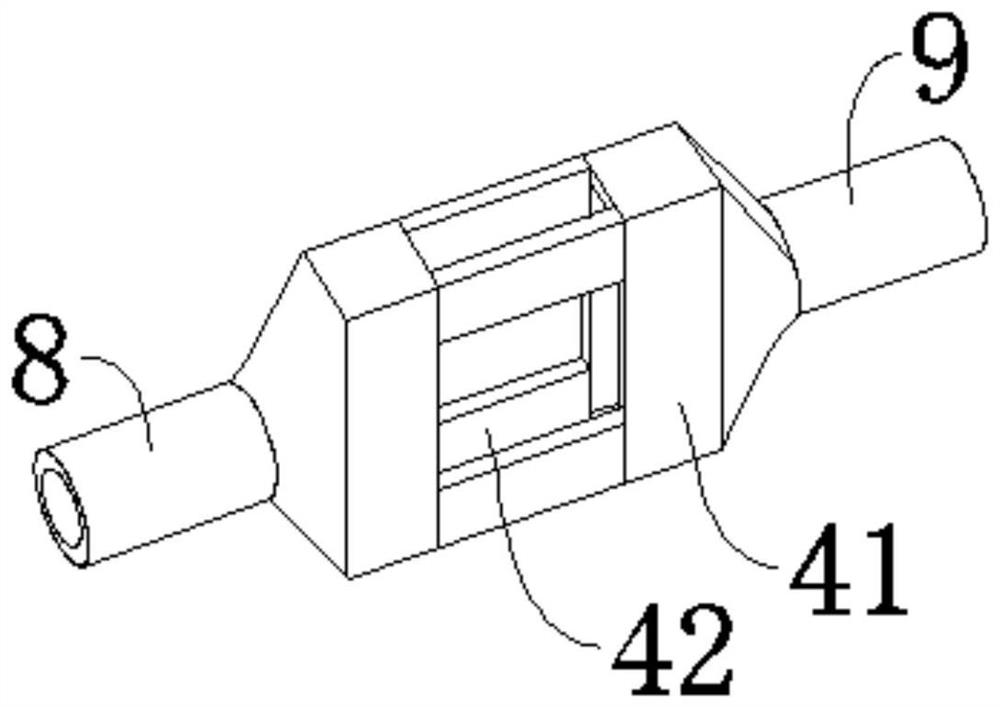

[0053] Embodiment 1: a kind of spore physical breaking device and method based on laser light energy, such as figure 1 , 3 , Shown in 4 and 5, the spore physical wall-breaking device includes a mixing tank 1, a pipeline pump 2, a light energy receiver 4, a laser, a flow controller, a water pump 5, a finished product tank 6 and a small sealed tank 7. The flow controller includes a first flow controller 31 and a second flow controller 32, a mixing tank 1, a pipeline pump 2, a first flow controller 31, a light energy receiver 4, a second flow controller 32, and a water pump 5 It is connected with the finished product barrel 6 in turn. The top of the mixing tank 1 is provided with a spore feed hopper 10 and a pure water inlet pipe 11, so that the spores and pure water are added into the mixing tank 1 and mixed by the mixing tank 1 to form a mixed solution. In order to quickly mix the spores and pure water evenly, preferably, the mixing tank 1 is equipped with a magnetic stirring...

Embodiment 2

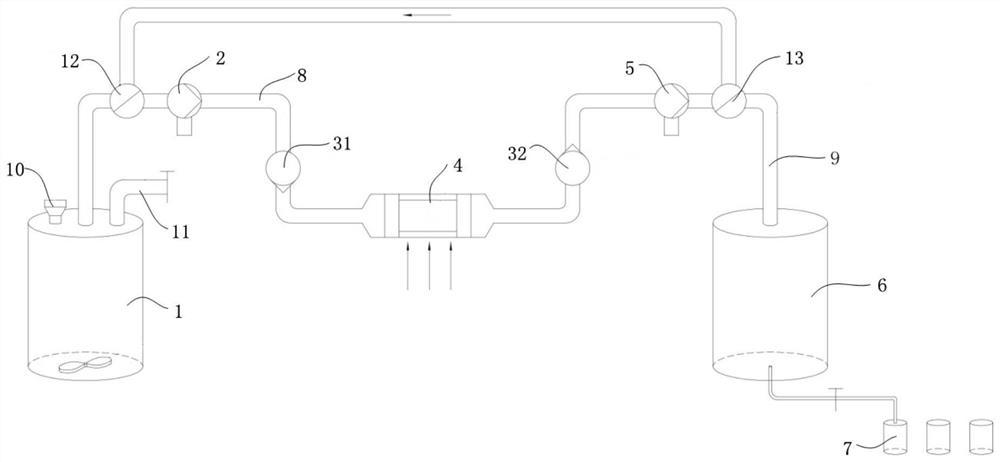

[0067] Embodiment 2: a kind of spore physical breaking device and method based on laser light energy, refer to figure 2 The difference between the spore physical wall breaking device and embodiment 1 is that the spore physical wall breaking device also includes a solenoid valve, and the solenoid valve includes a first solenoid valve 12 and a second solenoid valve 13 . The first electromagnetic valve 12 is installed between the mixing tank 1 and the pipeline pump 2 , and the second electromagnetic valve 13 is installed between the water pump 5 and the finished product tank 6 . The first electromagnetic valve 12 and the second electromagnetic valve 13 are connected in pipelines to send the mixed liquid back to the light energy receiver 4 again.

[0068] In the above-mentioned technical scheme, if the wall shell of some spores is hard and difficult to cycle once and just break the wall, under the condition of not increasing the light energy receiver 4 and the laser, the on / off s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com