Brown rice oat bread with low glycemic index and preparation method thereof

A low blood sugar, bread technology, applied in the direction of baking methods, dough processing, baked food with modified ingredients, etc., can solve the problems of easy collapse, poor taste, etc., to achieve reduced starch intake, small blood sugar fluctuations, specific volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the brown rice powder is as follows: put the brown rice raw material into a container, rinse the brown rice, dry at room temperature, pulverize in a normal temperature airflow conveying dry powder system, and pass the obtained brown rice powder through a 80-mesh sieve to obtain the brown rice powder. The starch content in the brown rice flour is 74.3%-76.4%, the protein content is 6.1%-7.3%, and the fat content is 0.3%-0.5%.

[0029] The preparation method of the oat flour is as follows: put the brown rice raw material into a container, rinse the oat grains, steam the oat grains at 100° C. for 30 minutes, and then dry them. Grinding is carried out in a normal temperature airflow conveying dry powder system, and the obtained oat flour passes through a 80-mesh sieve to obtain the oat flour. The starch content in the oat flour is 58.2%-60.5%, the protein content is 10.9%-11.3%, and the fat content is 6.2%-6.6%.

[0030] See Table 1 for the sensor...

Embodiment 1

[0034](1) In terms of mass parts, take by weighing 50 parts of brown rice flour, 50 parts of oat flour and gluten powder (the ratio of oat flour and gluten powder is respectively 25 parts: 25 parts, 20 parts: 30 parts, 15 parts : 35 parts, 10 parts: 40 parts), 1.6 parts of salt, 1 part of yeast, 1 part of improver, made into mixed powder;

[0035] (2) Add 100 parts of water to the mixed powder, stir at a low speed for 5 minutes, then stir at a high speed for 8 minutes until the dough is basically shaped, add 6 parts of butter and knead at a low speed until the gluten is fully developed to obtain a dough;

[0036] (3) said dough is carried out shaping, packing, and the dough after packing is 250g;

[0037] (4) Proof the dough after packing for 1 hour under the condition of humidity of 80% and temperature of 38° C., then bake and cool for 60 minutes at room temperature to obtain the brown rice oat bread product, wherein the baking is heated The temperature is 220°C, the lower h...

Embodiment 2

[0045] (1) In terms of parts by mass, take 50 parts of brown rice flour, 35 parts of gluten powder, 15 parts of oat flour, 1.6 parts of salt, 1 part of yeast, and 1 part of improver to make mixed powder;

[0046] (2) Add 100 parts of water to the mixed powder, stir at a low speed for 5 minutes, then stir at a high speed for 8 minutes until the dough is basically shaped, add 6 parts of butter and knead at a low speed until the gluten is fully developed to obtain a dough;

[0047] (3) said dough is carried out shaping, packing, and the dough after packing is 250g;

[0048] (4) Proof the dough for 50 minutes, 60 minutes, and 70 minutes respectively at a humidity of 80% and a temperature of 30°C or 38°C, then bake and cool for 60 minutes at room temperature to obtain the brown rice oatmeal bread The product, wherein, the baking temperature is 220°C, the lower firing temperature is 200°C, and the baking time is 30 minutes.

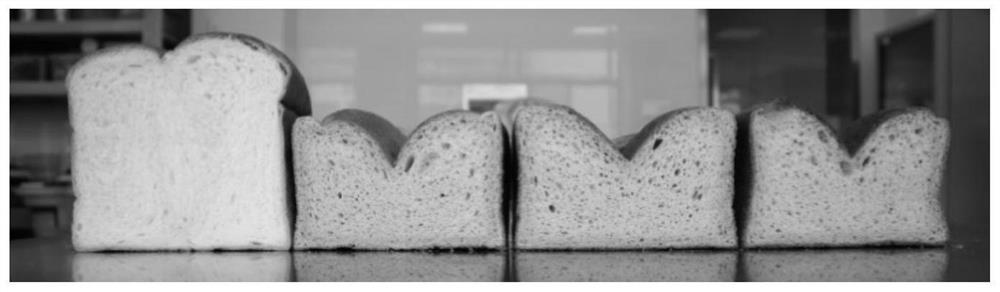

[0049] Related results see figure 1 with image 3 . f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com