Detector for measuring petroleum pipeline base metal defects

A technology for base metal and oil pipelines, which is applied in the field of detectors for measuring defects in the base metal of oil pipelines, can solve problems such as high cost, inapplicability, high detection environment requirements, and inability to detect internal cracks, so as to suppress pipeline safety accidents and offset direct The effect of coupled signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

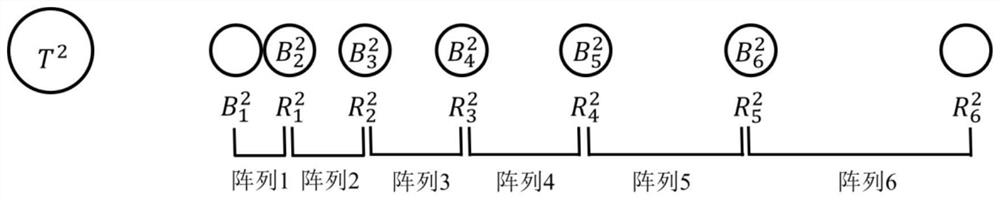

[0018] refer to figure 1 , a detector for measuring the metal defects of the oil pipeline matrix, including 3 sets of probes (refer to figure 1 , the dotted box is a group of probes), each group of probes includes 6 arrays, each array includes 1 transmitting coil T, 1 shielding coil B and 1 main receiving coil R, the shielding coil B and the main receiving coil R constitute The receiving coil system, that is, the 6 arrays of the first group of probes are T 1 , T 1 , T 1 , T 1 , T 1 , (The superscript of the above symbols is the probe group number, and the subscript is the array number, namely T 1 , first array for the first set of probes). The normal direction of all coils is orthogonal to the defect; the winding direction of the transmitting coil T (three transmitting coils) of the three sets of probes is the same; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com