Multi-chain polyolefin and styrene-containing composite modified asphalt for recycling and preparation method thereof

A styrene-based, composite modification technology, used in building components, building insulation materials, buildings, etc., can solve the problems of unstable quality, short duration of regeneration capacity, and insignificant recovery of indicators, and achieves the increase of microcosm. The effect of surface roughness, improved adhesion and surface activity, overall performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

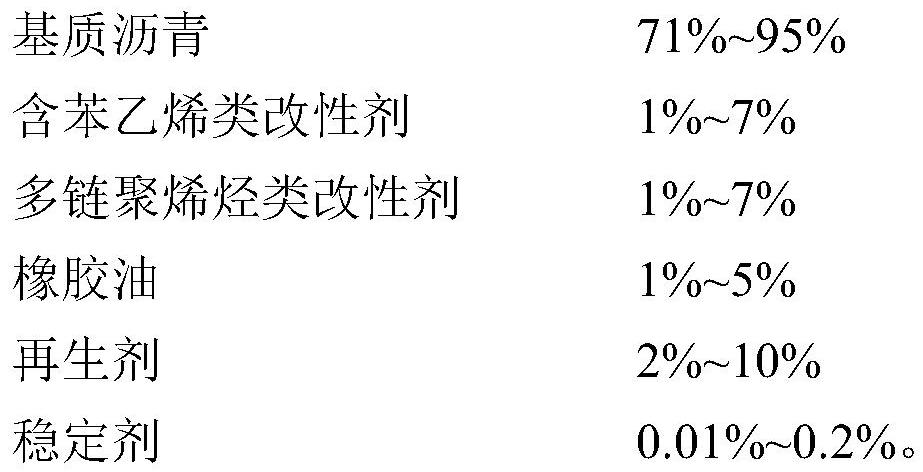

[0024] A multi-chain polyolefin and styrene-containing compound modified asphalt for regeneration, the base asphalt, styrene-containing modifier, multi-chain polyolefin modifier, rubber oil, naphthenic oil regeneration agent, The mass percentages of each component of the stabilizer are as follows:

[0025]

[0026] (1) Heat the base asphalt to 165-180°C in the reaction kettle, add a styrene-containing modifier after the temperature is stable, stir for 0.5-1h until it is uniform, and pass the evenly stirred asphalt through a colloid mill for high-speed shearing Cutting, the shearing power is 20-40t / h. After the shearing is completed, stir for 0.5h to 1h; then add a multi-chain polyolefin modifier and continue to stir for 0.5 to 1h.

[0027] (2) Add rubber oil to the bitumen obtained in step (1), and stir at a temperature of 170-180°C for 0.5h-1h. Then slowly add a stabilizer, stir for 2-3 hours, then add a naphthenic oil regeneration agent at a temperature of 170-180°C and...

Embodiment 2

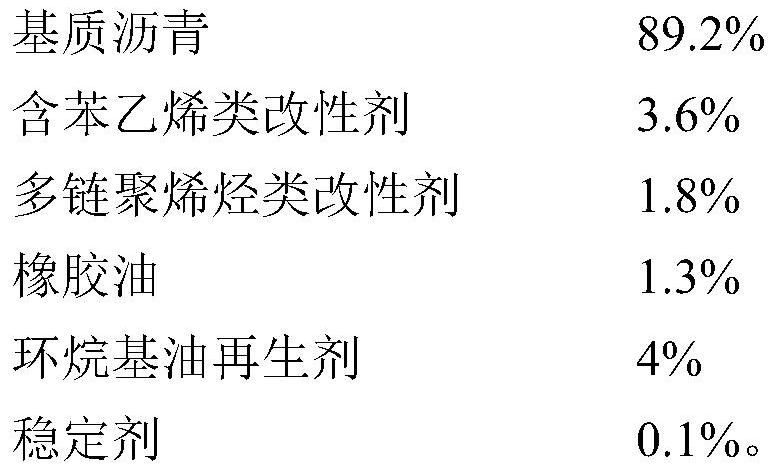

[0033] A multi-chain polyolefin and styrene-containing compound modified asphalt for regeneration, the base asphalt, styrene-containing modifier, multi-chain polyolefin modifier, rubber oil, naphthenic oil regeneration agent, The mass percentages of each component of the stabilizer are as follows:

[0034]

[0035] (1) Heat the base asphalt in the reaction kettle to 165-180°C, add a styrene-containing modifier after the temperature is stable, stir for 0.5-1h until it is uniform, and pass the evenly stirred asphalt through a colloid mill for high-speed Shearing, the shearing power is 20-40t / h. After the shearing is completed, stir for 0.5h to 1h; then add a multi-chain polyolefin modifier and continue to stir for 0.5 to 1h.

[0036] (2) Add rubber oil to the bitumen obtained in step (1), and stir at a temperature of 170-180°C for 0.5h-1h. Then slowly add a stabilizer, stir for 2-3 hours, then add a naphthenic oil regeneration agent at a temperature of 170-180°C and continu...

Embodiment 3

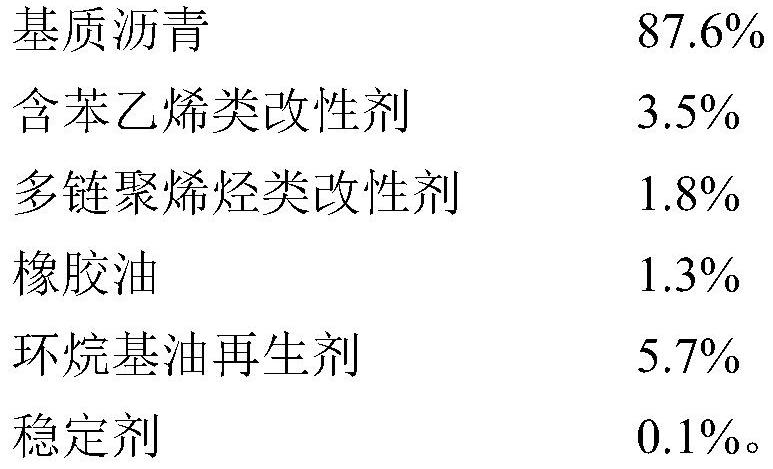

[0042] A multi-chain polyolefin and styrene-containing compound modified asphalt for regeneration, the base asphalt, styrene-containing modifier, multi-chain polyolefin modifier, rubber oil, naphthenic oil regeneration agent, The mass percentages of each component of the stabilizer are as follows:

[0043]

[0044]

[0045] (1) Heat the base asphalt in the reaction kettle to 165-180°C, add a styrene-containing modifier after the temperature is stable, stir for 0.5-1h until it is uniform, and pass the evenly stirred asphalt through a colloid mill for high-speed Shearing, the shearing power is 20-40t / h. After the shearing is completed, stir for 0.5h to 1h; then add a multi-chain polyolefin modifier and continue to stir for 0.5 to 1h.

[0046] (2) Add rubber oil to the bitumen obtained in step (1), and stir at a temperature of 170-180°C for 0.5h-1h. Then slowly add a stabilizer, stir for 2-3 hours, then add a naphthenic oil regeneration agent at a temperature of 170-180°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stability | aaaaa | aaaaa |

| stability | aaaaa | aaaaa |

| stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com