Method for intensifying heavy metal trapping in desulfurization tower by using magnetic medium and application thereof

A magnetic medium and desulfurization tower technology, applied in the field of heavy metal capture, can solve the problems of high operating cost, large consumption of chemical reagents, and unsuitability for large-scale industrial production, so as to ensure long-term stable operation, reduce construction cost, and low operating cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

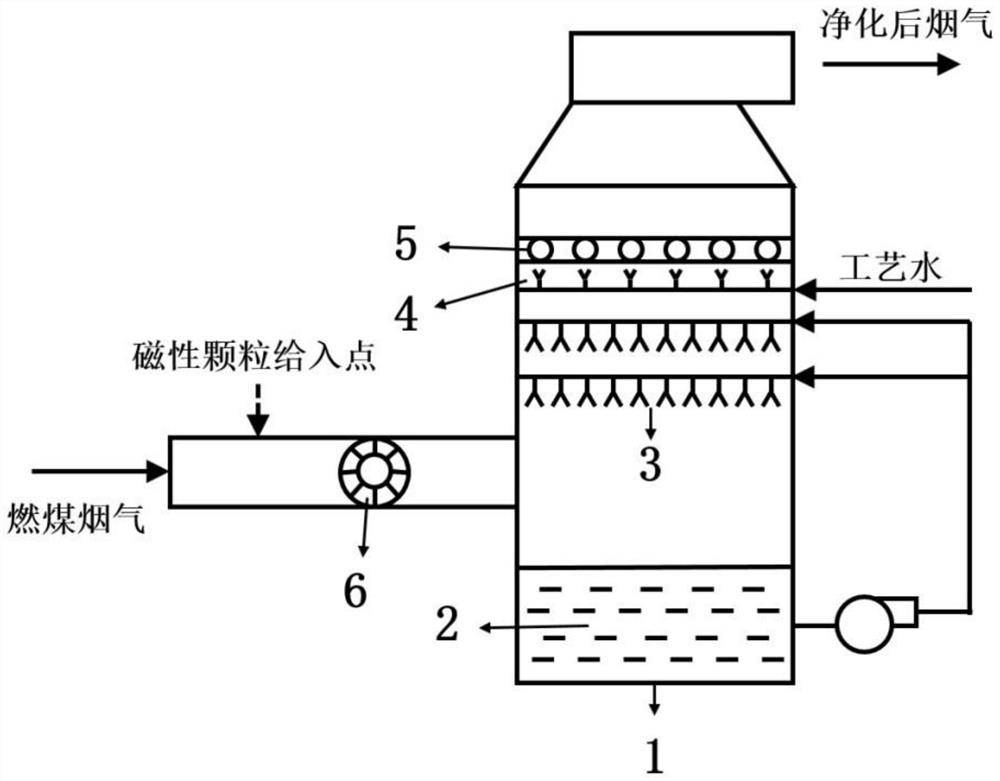

[0044] Application object: a wet flue gas desulfurization device in a power plant, the inlet flue gas volume is 1670000m 3 / h (standard state, wet basis), the selenium concentration in the inlet flue gas is 127μg / m 3 , the flue gas temperature at the entrance is 109°C, the slurry temperature inside the desulfurization tower is 56°C, the operating liquid-gas ratio of the desulfurization tower is 15, and the desulfurization tower is equipped with three spray layers.

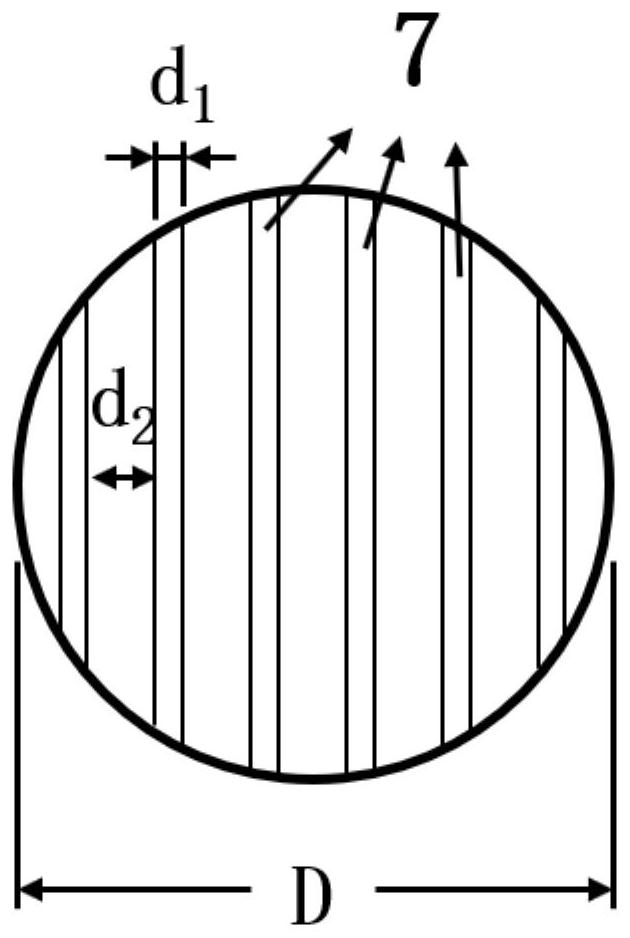

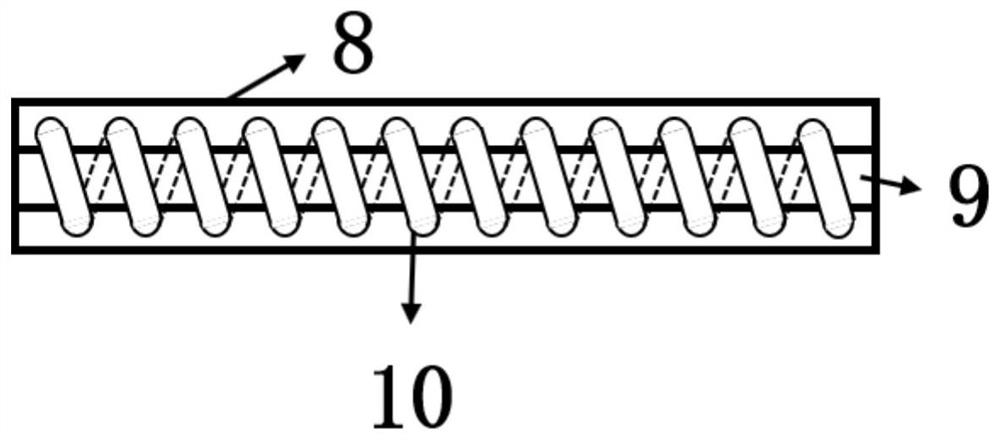

[0045] Operation process: Use a uniform feeder to feed γ-Fe with a particle size of 5 μm 2 o 3 The powder is fed in at a rate of 1.67kg / h from the front flue of the booster fan at the entrance of the desulfurization tower; a magnetic adsorption layer is installed in the desulfurization tower, located 2.5m above the first spray layer, and the diameter of the electromagnetic rod is 0.4m, the ratio of the tube spacing to the tube diameter of the parallel electromagnetic rod tube bundle is 8, and the flushing nozzle ...

Embodiment 2

[0048] Application object: a wet flue gas desulfurization device in a power plant, the inlet flue gas volume is 3560000m3 3 / h (standard state, wet basis), the selenium concentration in the inlet flue gas is 71μg / m 3 , The flue gas temperature at the entrance is 112°C, the slurry temperature inside the desulfurization tower is 57°C, the operating liquid-gas ratio of the desulfurization tower is 17, and the desulfurization tower is equipped with three spray layers.

[0049] Operation process: use a uniform feeder to feed Fe with a particle size of 10 μm 3 o 4 The powder is fed in at a constant speed from the front flue of the booster fan at the entrance of the desulfurization tower at a rate of 0.71kg / h; a magnetic adsorption layer is installed in the desulfurization tower, located 2.5m above the first spray layer, and the diameter of the electromagnetic rod is 0.3m, the ratio of the tube spacing to the tube diameter of the parallel electromagnetic rod tube bundle is 10, and ...

Embodiment 3

[0052] Application object: a wet flue gas desulfurization device in a power plant, the inlet flue gas volume is 530000m 3 / h (standard state, wet basis), the selenium concentration in the inlet flue gas is 63μg / m 3 , The flue gas temperature at the entrance is 114°C, the slurry temperature inside the desulfurization tower is 56°C, the operating liquid-gas ratio of the desulfurization tower is 17, and the desulfurization tower is equipped with three spray layers.

[0053] Operation process: use a uniform feeder to feed Co with a particle size of 20 μm 3 o 4 The powder is fed at a constant speed of 0.11kg / h from the front flue of the booster fan at the entrance of the desulfurization tower; a magnetic adsorption layer is installed in the desulfurization tower, which is located 2m above the first spray layer, and the diameter of the electromagnetic rod is 0.4 m, the ratio of the tube spacing to the tube diameter of the parallel electromagnetic rod tube bundle is 10, and the flu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com