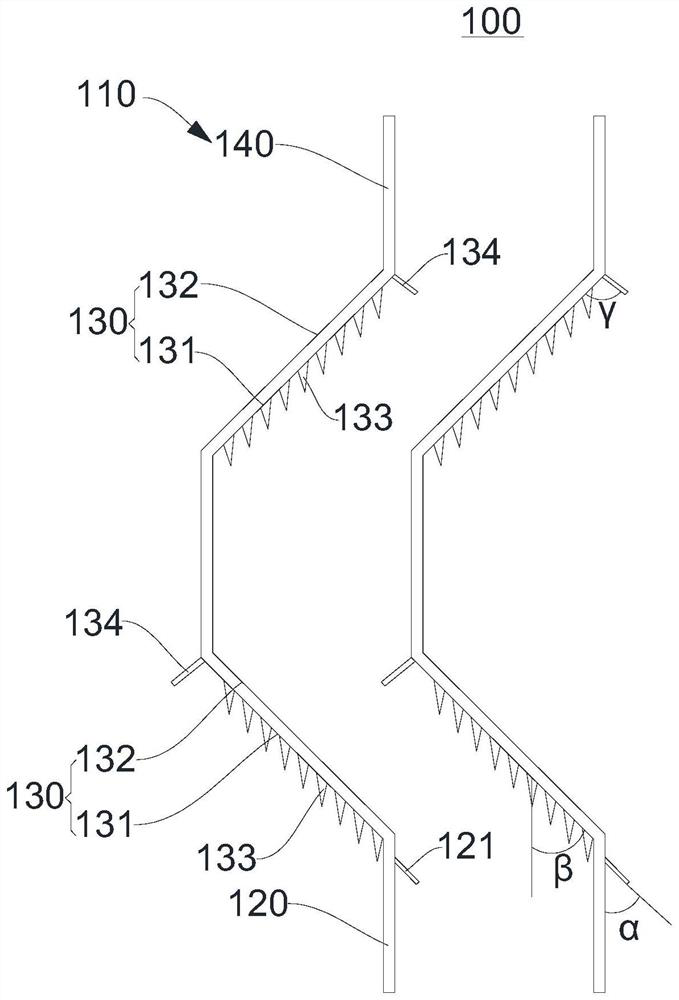

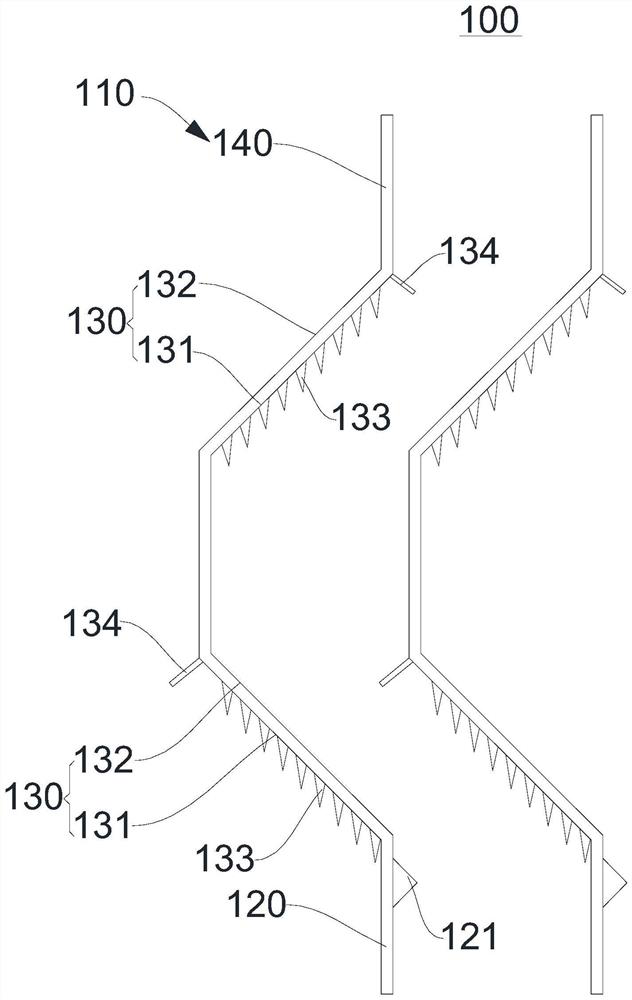

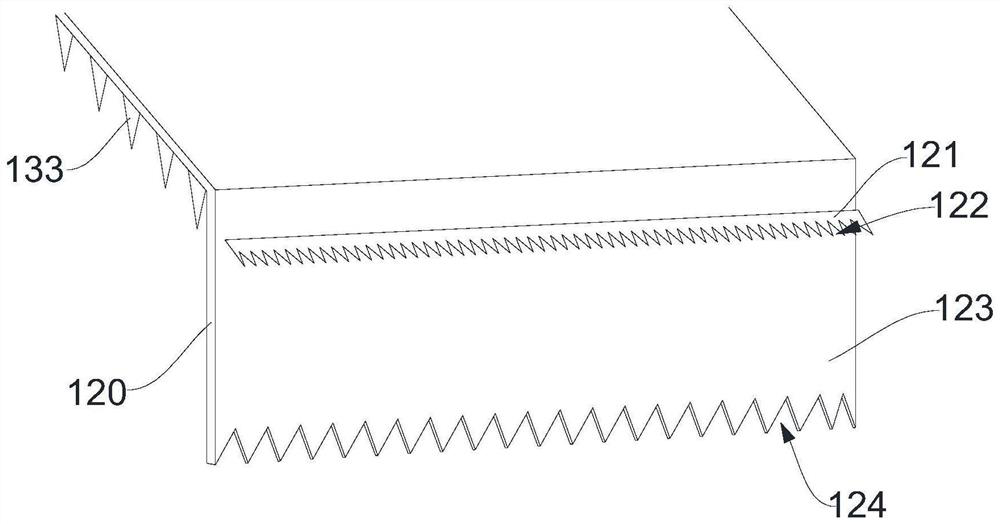

Efficient baffle plate and efficient baffle plate demister

A baffle plate, high-efficiency technology, applied in chemical instruments and methods, separation methods, human health protection, etc., can solve the problem of long-term use of baffle plate demisters, limited liquid discharge rate of baffle plate demisters, Affect the operation flexibility and stability of the device, etc., to ensure long-term stable operation, improve separation efficiency and operation flexibility, and increase the effect of liquid capture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

Specific examples:

[0060] Case 1: The operating gas volume is 500m 3 / h, the water content of the inlet liquid phase is 1000mg / m 3 , using the baffle 110 without surface treatment, the discharge rate of liquid is 428.0kg / h, and the total efficiency of gas-liquid separation is 85.6%; The discharge rate of the obtained liquid is 473.0kg / h, and the total efficiency of gas-liquid separation is 94.6%; the total efficiency of gas-liquid separation is increased by 9.0%.

[0061] Case 2: The operating gas volume is 2000m 3 / h, the water content of the inlet liquid phase is 1000mg / m 3 , using the baffle plate 110 without surface treatment, the discharge rate of liquid is 1.716t / h, and the total efficiency of gas-liquid separation is 85.8%; under the same operating conditions, the high-efficiency baffle plate 100 proposed in this application is used to remove fog The discharge rate of the obtained liquid is 1.912t / h, and the total efficiency of gas-liquid separation is 95.6%; the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com