Chemical agglomeration wet desulphurization device for reducing generation of fine particles

A technology of chemical agglomeration and wet desulfurization, which is applied in the direction of chemical instruments and methods, separation methods, and dispersed particle separation, can solve the problems of low cost, high investment and operation costs, and difficult practical stages, so as to improve capture, investment and operation. Low cost, effect of changing growth habit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

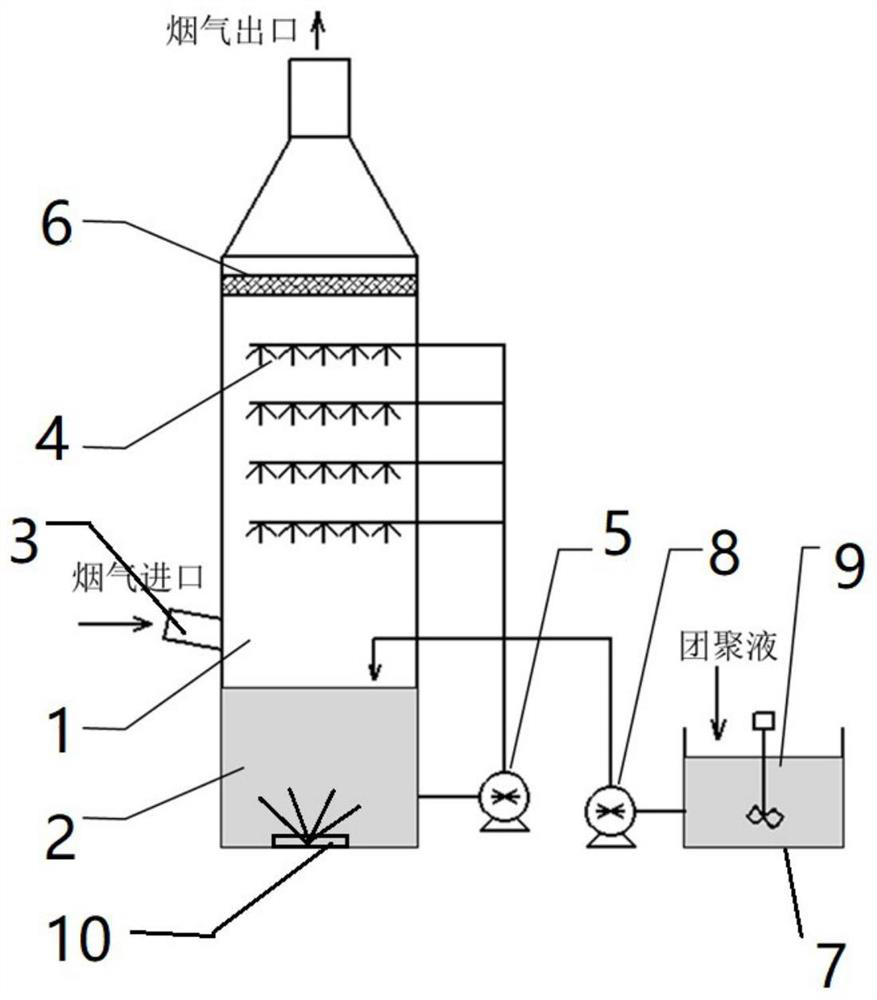

[0019] Such as figure 1 The chemical agglomeration wet desulfurization device shown to reduce the generation of fine particles includes:

[0020] A desulfurization tower 1, the bottom of the desulfurization tower 1 is equipped with a desulfurization slurry 2, and a flue gas inlet 3 is provided at the same time, and a spray assembly 4 is provided at a position above the flue gas inlet 3 in the desulfurization tower 1, and the spray assembly 4 In order to arrange multi-layer spray heads at intervals from bottom to top, the spray assembly 4 communicates with the desulfurization slurry 2 through the slurry circulation pump 5, and a first demister 6 is arranged above the spray assembly 4, and the spray assembly 4 The desulfurization slurry 2 is dispersed and circulated inside the desulfurization tower 1 under the action of the slurry circulation pump 5 to desulfurize the flue gas. discharge.

[0021] The reunion liquid container 7 is communicated with the desulfurization tower 1 ...

Embodiment 2

[0027] The other parameters of the above method remain unchanged. The agglomerating agent is polyaluminum iron silicate, and the addition amount is 0.5g per L of desulfurization slurry. The wetting agent is sodium dodecylbenzenesulfonate, and the addition amount is 0.05g per L of desulfurization slurry. The desulfurization slurry temperature is 35°C, and the desulfurization liquid-gas ratio is 12L / m 3 . After the system is stable, use the electric low-pressure impactor ELPI to test online, and the mass concentration of fine particles in the net flue gas at the outlet of the desulfurization tower is about 39.3mg / Nm 3 , the number concentration of fine particles is 1.5×10 7 1 / cm 3 .

Embodiment 3

[0029] The other parameters of the above-mentioned method remain unchanged, the agglomerating agent is selected from squash gum, chitosan, and sodium carboxymethyl cellulose, and the addition amount is 0.35g per L of desulfurization slurry, and the wetting agent is selected from sodium dodecylbenzenesulfonate. The amount of addition is 0.035g per L of desulfurization slurry, the temperature of desulfurization slurry is 40°C, and the desulfurization liquid-gas ratio is 18L / m 3 . After the system is stable, use the electric low-pressure impactor ELPI online test, and the mass concentration of fine particles in the net flue gas at the outlet of the desulfurization tower is about 37.5mg / Nm 3 , the number concentration of fine particles is 1.4×10 7 1 / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com