High-frequency NO-PLIF imaging measurement device and method

A NO-PLIF, imaging measurement technology, used in measurement devices, color/spectral property measurement, material analysis by optical means, etc. , poor light stability, etc., to achieve the effect of high spatial resolution and temporal resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but only to illustrate the essence of the technical solutions of the present invention.

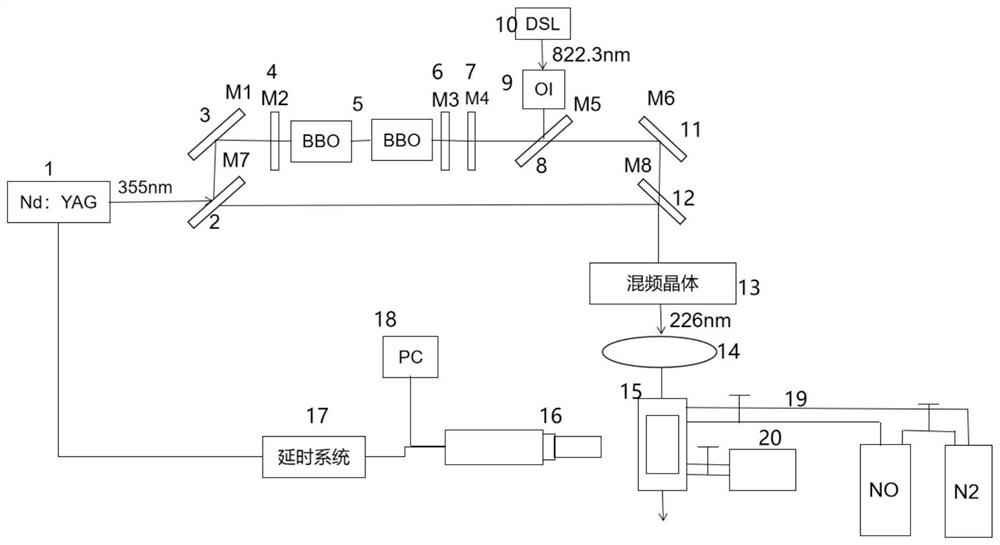

[0056] figure 1 A schematic diagram of the high-frequency NO-PLIF imaging measurement experimental device of the present invention is shown. Among them, the high-frequency NO-PLIF imaging measurement experiment equipment includes a high-frequency laser 1, a first mirror 2, a first mirror 3, a third mirror 4, a BBO crystal 5, a fourth mirror 6, a fifth mirror 7, a second Lens 8, optical isolator (OI, Optical isolator) 9, seed laser (DSL) 10, second mirror 11, third mirror 12, mixing crystal (mixing crystal) 13, convex lens 14, standard gas p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Line width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com