An anti-floating anchor pile connecting device

A technology of anti-floating anchor rods and pile barrels, which is applied in hoisting devices, protection devices, lifting equipment braking devices, etc., and can solve problems such as waste of resources and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

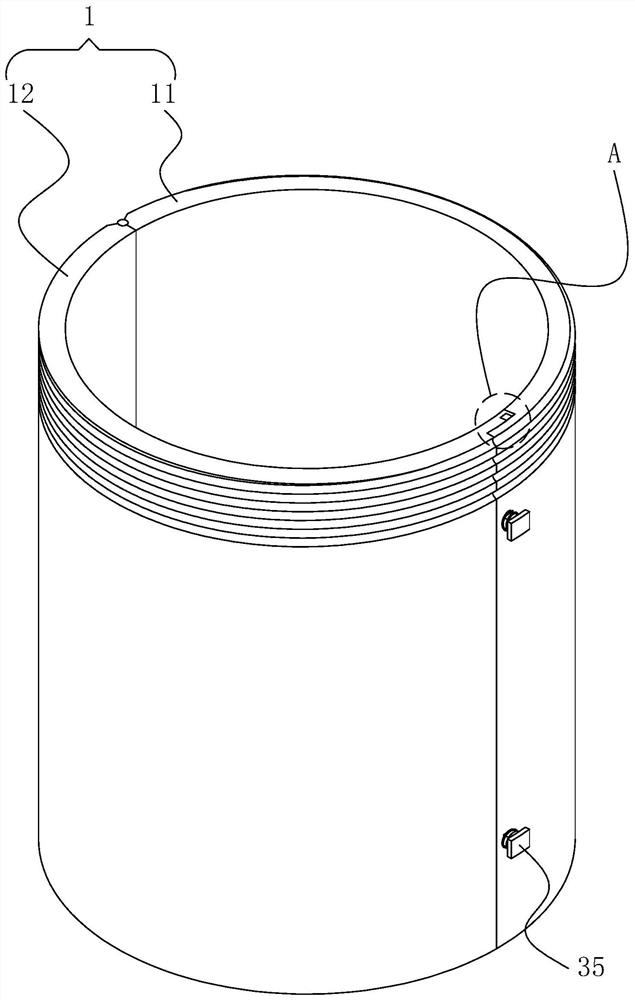

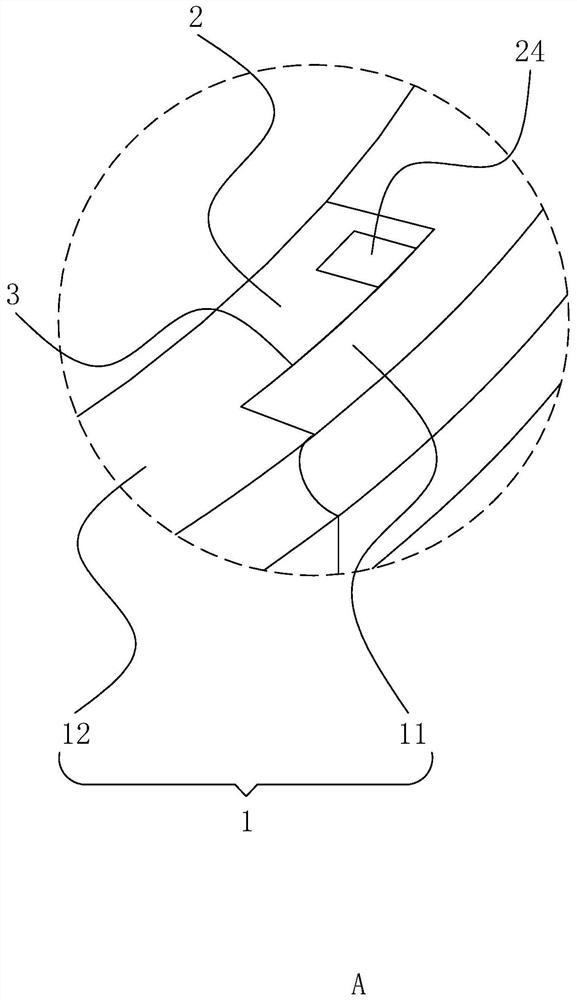

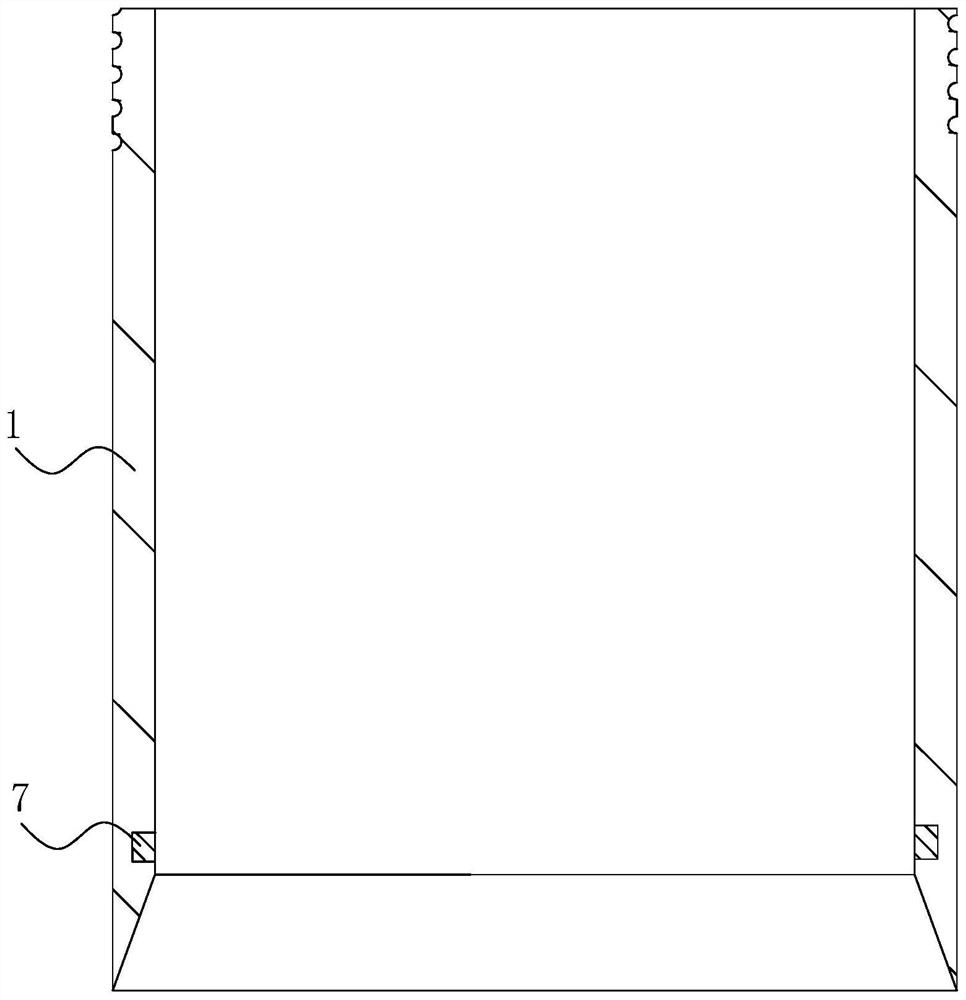

[0043] refer to figure 1 and figure 2 , a borehole is vertically opened on the ground, and the original pile head is fixed in the borehole, and a number of anti-floating anchor rods are fixedly inserted in the original pile head, and the top of the anti-float anchor rod extends 4 holes and bends outwards. The anti-floating anchor pile receiving device includes a pile connecting tube 1 that is vertically arranged and opened up and down. The pile connecting tube 1 is divided into a first arc plate 11 and a second arc plate 12 along the vertical direction, and the first arc plate 11 and the second arc plate 12 One side of the second arc plate 12 is hinged, and the hinge axis is vertically arranged. The end of the first arc plate 11 away from its hinge is provided with an arc-shaped dismounting groove 3, and the end of the second arc plate 12 away from its hinge is fixedly connected. There is an arc-shaped dismounting plate 2, a dismounting groove 3 for the dismounting plate 2 t...

Embodiment 2

[0050] refer to Figure 7 The difference between this embodiment and Embodiment 1 is that a connecting assembly is provided between the connecting cylinder 45 and the pile receiving cylinder 1, and the connecting assembly includes a flashing plate 5, a locking bar 53, a fixing spring 54 and a fixing plate 55, and the flashing plate 5 Slidingly connected to the lower end surface of the connecting cylinder 45, the top of the peripheral outer wall of the pile connecting cylinder 1 is provided with a slot 51 for inserting one end of the inserting plate 5, and the bottom end of the peripheral outer wall of the connecting cylinder 45 is provided with a fixing groove 6 The lower surface of the flashboard 5 is vertically provided with a fixing hole 52 connected to the fixing groove 6, the top of the outer wall of the locking bar 53 is hinged to one end of the fixing plate 55, and the angle between the fixing plate 55 and the locking bar 53 is an acute angle. The fixed spring 54 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com