Composite test material for testing whether water enters cable and preparation method and application thereof

A technology for testing cables and water ingress, which is applied in the direction of analyzing materials through chemical reactions and material analysis through observing the impact on chemical indicators, etc. It can solve problems such as insufficient reliability, troublesome process, and low resolution. Achieve excellent water absorption, strong recognition, and high resolution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

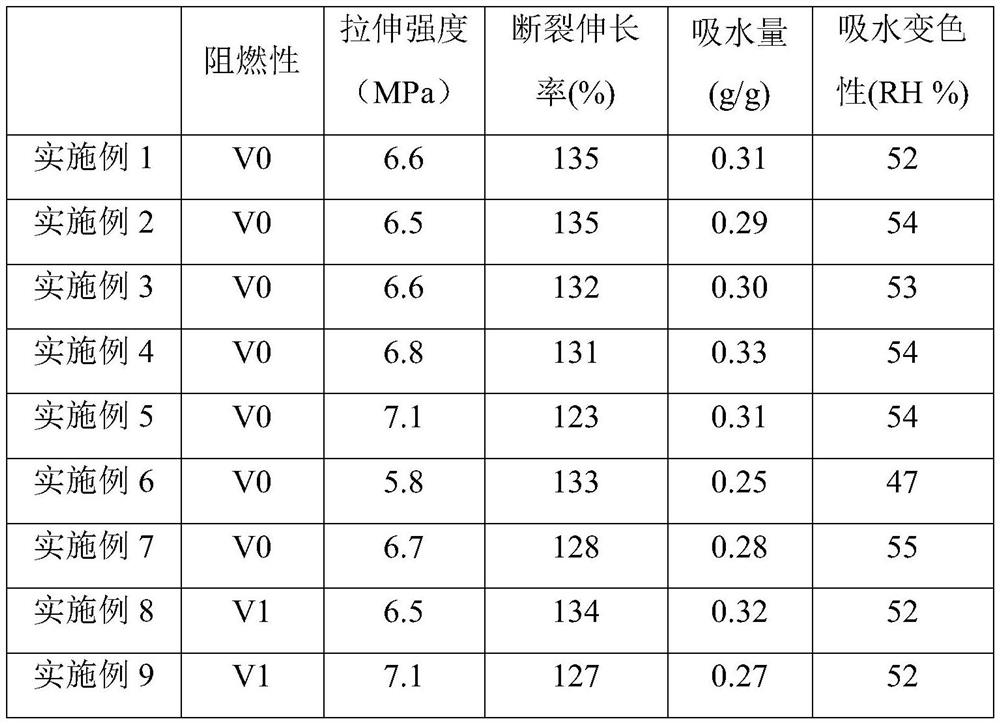

Examples

preparation example 1

[0042] (1) The aqueous solution of monomeric acrylic acid and acrylamide is fed in a certain molar ratio, heated to reflux at 90°C under an inert atmosphere, and 0.3wt% of the total monomer mass is added as an initiator potassium persulfate-sodium bicarbonate (1:1, w / w) Initiate the polymerization reaction for 0.5-1h;

[0043] (2) Add 3,3'-diallyl diphenol (the molar ratio of acrylic acid, acrylamide, 3,3'-diallyl diphenol is 5:1:0.1), continue at 80 React at -90°C for 6 hours, dehydrate, cool, wash, and dry to obtain a water-absorbent resin, hereinafter referred to as water-absorbent resin 1. The weight-average molecular weight of the water-absorbent resin obtained through GPC test was 957200 g / mol, and PDI=1.92.

preparation example 2

[0045] Other conditions and steps are the same as in Preparation Example 1, except that the molar ratio of acrylic acid, acrylamide, and 3,3'-diallyl biphenol is 5:1:0.2. The weight-average molecular weight of the water-absorbing resin obtained through GPC test was 1268400 g / mol, and PDI=2.13. Hereinafter, it is referred to as water-absorbent resin 2 .

preparation example 3

[0047] Other conditions and steps are the same as in Preparation Example 1, except that the molar ratio of acrylic acid, acrylamide, and 3,3'-diallyl biphenol is 5:1:0.3. The weight-average molecular weight of the water-absorbent resin obtained through GPC test was 1457100 g / mol, and PDI=2.28. Hereinafter, it is referred to as water-absorbent resin 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com