Anti-bleeding polymer, low-retraction filling solid waste material, preparation method and application

A technology of polymers and polymer particles, which is applied in the field of low shrinkage filling solid waste materials and preparation, and anti-bleeding polymers, to achieve the effects of improving strength, increasing the rate of connection, and increasing the amount of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

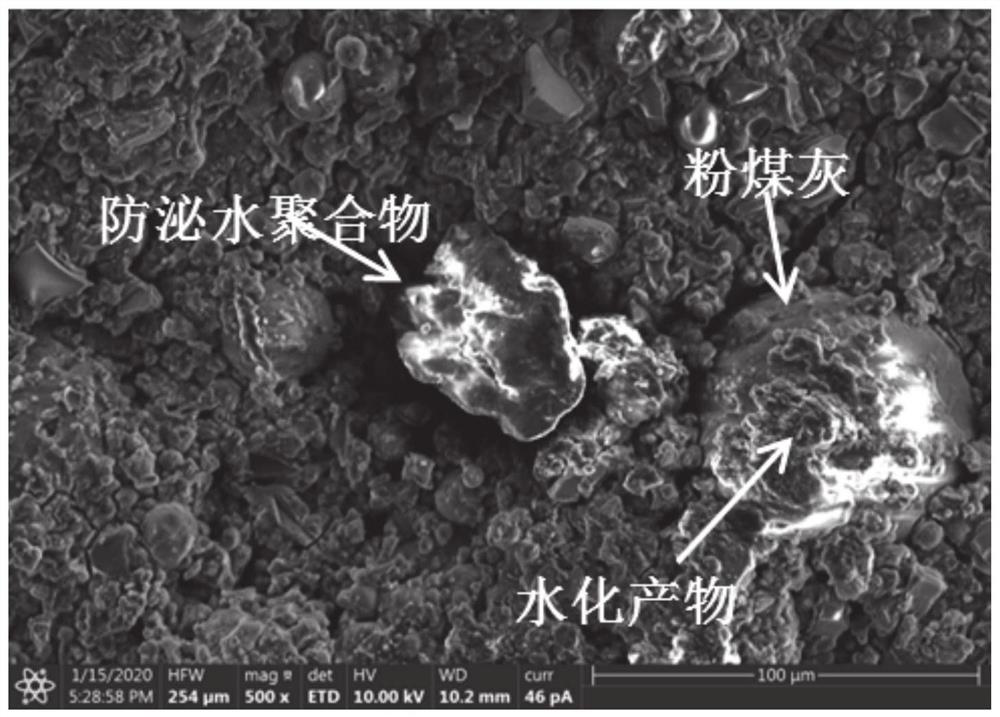

Image

Examples

preparation example Construction

[0055] In a second aspect, the present invention provides a method for preparing the anti-bleeding polymer, comprising the steps of:

[0056] preparing an acrylic acid solution, adding acrylamide to it to obtain a hydrophilic monomer solution;

[0057] Add a crosslinking agent to the hydrophilic monomer solution, mix and dissolve, then add an initiator therein, heat up and polymerize to form a polymer gel;

[0058] Grinding the polymer gel into particles, and adding sodium hydroxide solution to it for neutralization reaction;

[0059] drying the neutralized gel particles, further pulverizing and sieving to obtain primary anti-bleeding polymer particles;

[0060] The surface crosslinking agent solution is sprayed on the surface of the primary anti-bleeding polymer particles, and dried to obtain the final product.

[0061] In some embodiments, the mass percentage of acrylic acid in the acrylic acid solution is 10%-70%. Because as the concentration of acrylic acid increases, e...

Embodiment 1

[0091] An anti-retraction filling solid waste material and a preparation method thereof, comprising the following steps:

[0092] Step 1: Weigh raw materials by mass fraction, including 500 parts of fly ash, 500 parts of blast furnace slag, 30 parts of water glass, 100 parts of Portland cement, 300 parts of water, 10 parts of sodium hydroxide, anti-bleeding polymer 5 servings. Wherein the synthetic preparation method of anti-bleeding polymer is as follows:

[0093] Step 2: take 300g of acrylic acid and dilute it into an acrylic acid solution with a mass fraction of 40%, add 100g of acrylamide, fully stir to dissolve it, and obtain a hydrophilic monomer solution A;

[0094] Add 3g of cross-linking agent to the above-mentioned obtained hydrophilic monomer solution A, fully stir to dissolve it;

[0095] Add 3g of ammonium persulfate, stir well to dissolve it, start the polymerization reaction by raising the temperature to 70°C externally, and let it stand for 1 hour to form a p...

Embodiment 2

[0120] An anti-retraction filling solid waste material and a preparation method thereof, comprising the following steps:

[0121] Step 1: Weigh raw materials by mass fraction, including 700 parts of fly ash, 500 parts of blast furnace slag, 50 parts of water glass, 200 parts of Portland cement, 400 parts of water, 100 parts of sodium hydroxide, anti-bleeding polymer 8 servings. Wherein the synthetic preparation method of anti-bleeding polymer is as follows:

[0122] Step 2: take 300g of acrylic acid and dilute it into an acrylic acid solution with a mass fraction of 50%, add 100g of acrylamide, stir well to dissolve it, and obtain a hydrophilic monomer solution B;

[0123] Add 0.6 g of cross-linking agent to the hydrophilic monomer solution B obtained above, stir well to dissolve it;

[0124] Add 1g of potassium persulfate as an initiator, stir well to dissolve, heat up to 90°C externally to initiate polymerization, and let it stand for 1 hour to form a polymer gel;

[0125...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com