Inclined rail numerical control lathe

A technology of CNC lathes and inclined rails, which is applied in the field of CNC lathes, can solve the problems of wear and loosening, affecting the sliding and acceleration of the seat body, and achieve the effect of avoiding overfilling and preventing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

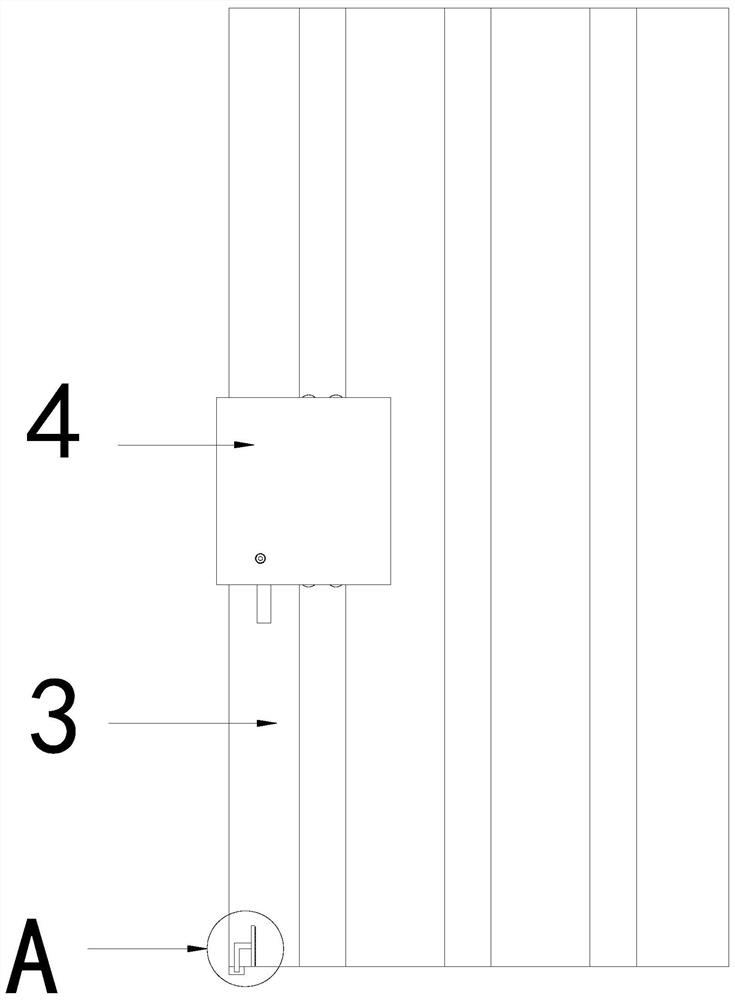

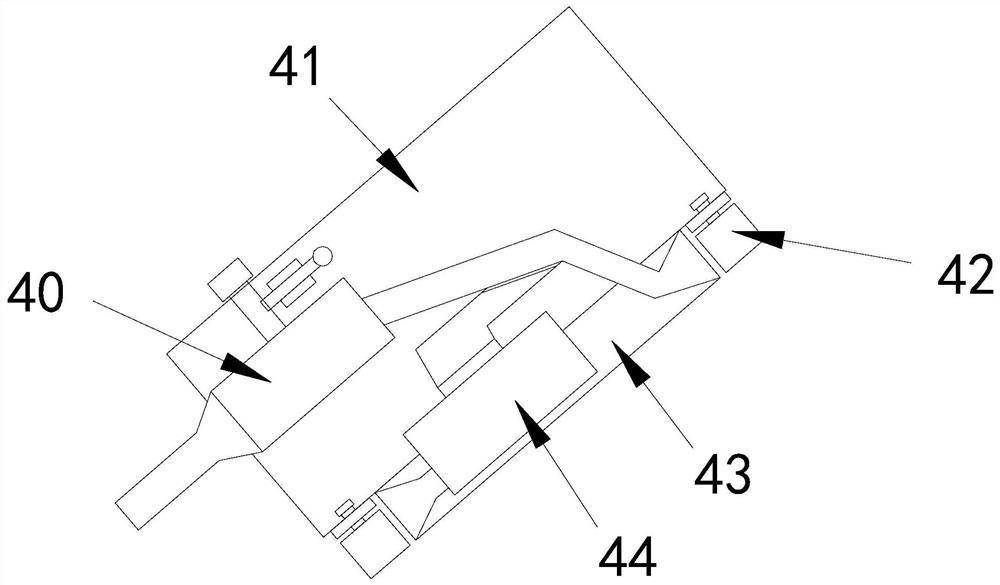

[0032] see Figure 1-8 , The present invention provides a technical scheme of a CNC lathe with inclined rail: its structure includes a base 1, a work box 2, an inclined guide rail 3, a clamp seat 4, a tool rest 5, and a controller 6, and the base 1 is connected with a work box 2, A controller 6 is connected to the outside of the work box 2, and a tool holder 5 and an inclined guide rail 3 are respectively installed on the left and right sides of the inside of the work box 2. A clamp seat 4 is installed on the inclined guide rail 3, and the clamp base 4 includes a set Dust structure 40, seat 41, cleaning wheel 42, slider 43, fan 44, the bottom of the seat 41 is provided with a slider 43 and the two are an integrated structure, the two ends of the slider 43 are respectively provided with cleaning The cleaning wheel 42 is installed at the bottom of the seat body 41. The seat body 41 is provided with a dust collecting structure 40, and the dust collecting structure 40 is communica...

Embodiment 2

[0035] see Figure 1-10, The present invention provides a technical scheme of a CNC lathe with inclined rail: its structure includes a base 1, a work box 2, an inclined guide rail 3, a clamp seat 4, a tool rest 5, and a controller 6, and the base 1 is connected with a work box 2, A controller 6 is connected to the outside of the work box 2, and a tool holder 5 and an inclined guide rail 3 are respectively installed on the left and right sides of the inside of the work box 2. A clamp seat 4 is installed on the inclined guide rail 3, and the clamp base 4 includes a set Dust structure 40, seat 41, cleaning wheel 42, slider 43, fan 44, the bottom of the seat 41 is provided with a slider 43 and the two are an integrated structure, the two ends of the slider 43 are respectively provided with cleaning The cleaning wheel 42 is installed at the bottom of the seat body 41. The seat body 41 is provided with a dust collecting structure 40, and the dust collecting structure 40 is communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com