Industrial air purification device

A kind of air purification equipment and industrial technology, applied in the direction of climate change adaptation, climate sustainability, chemical instruments and methods, etc., can solve the problems of troublesome replacement, easy dust cleaning of cloth bags, etc., reduce manpower, facilitate dust cleaning, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

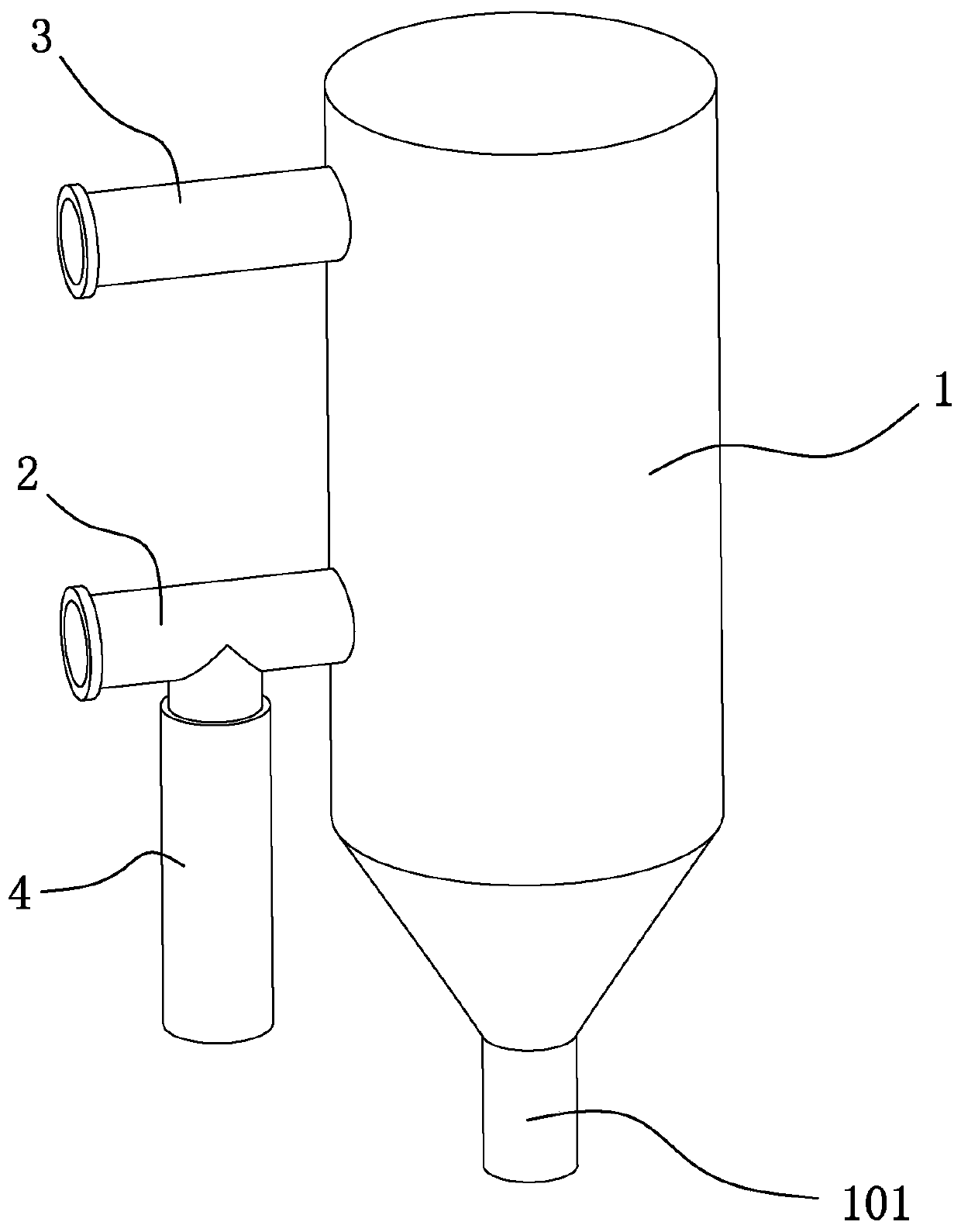

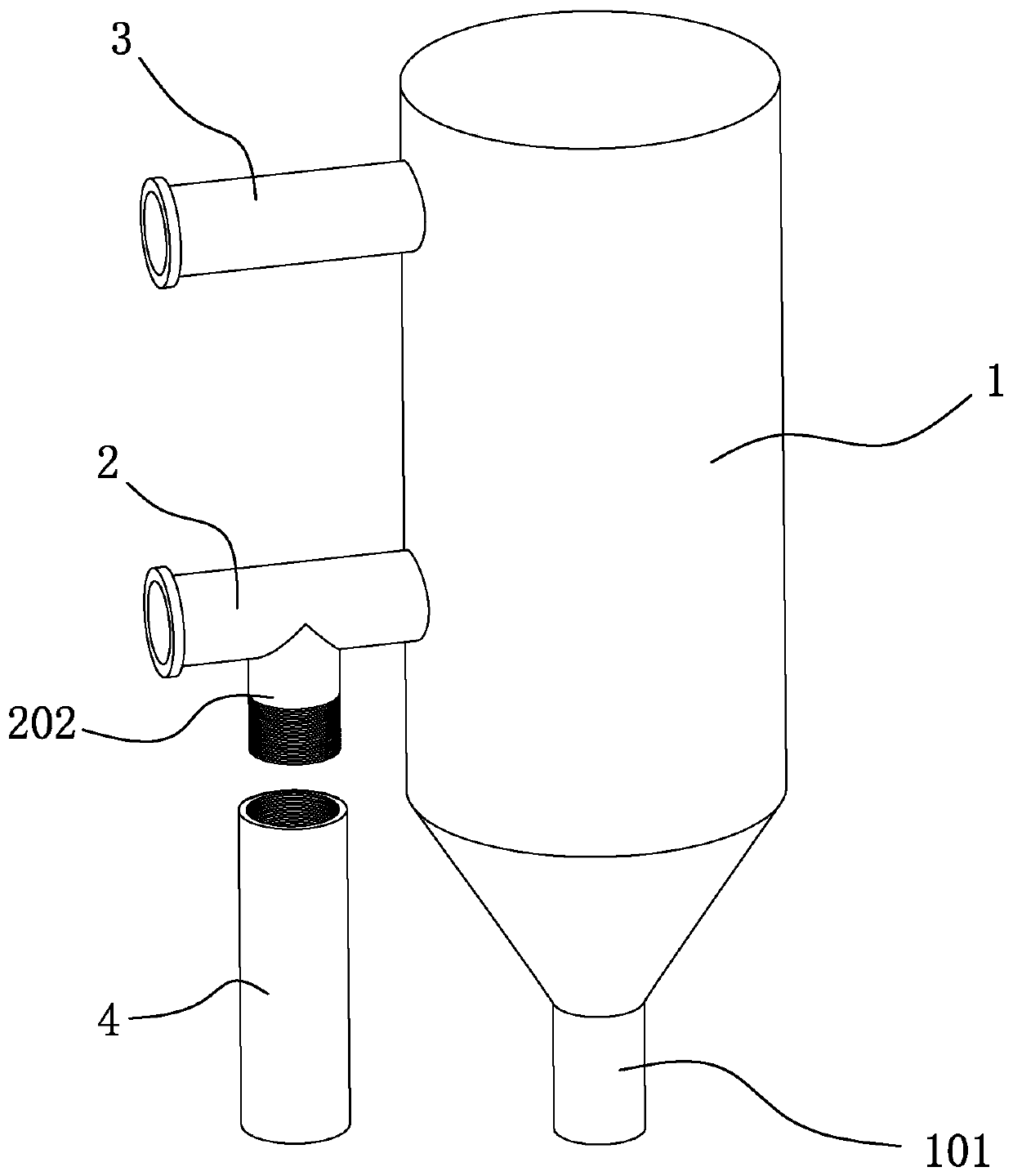

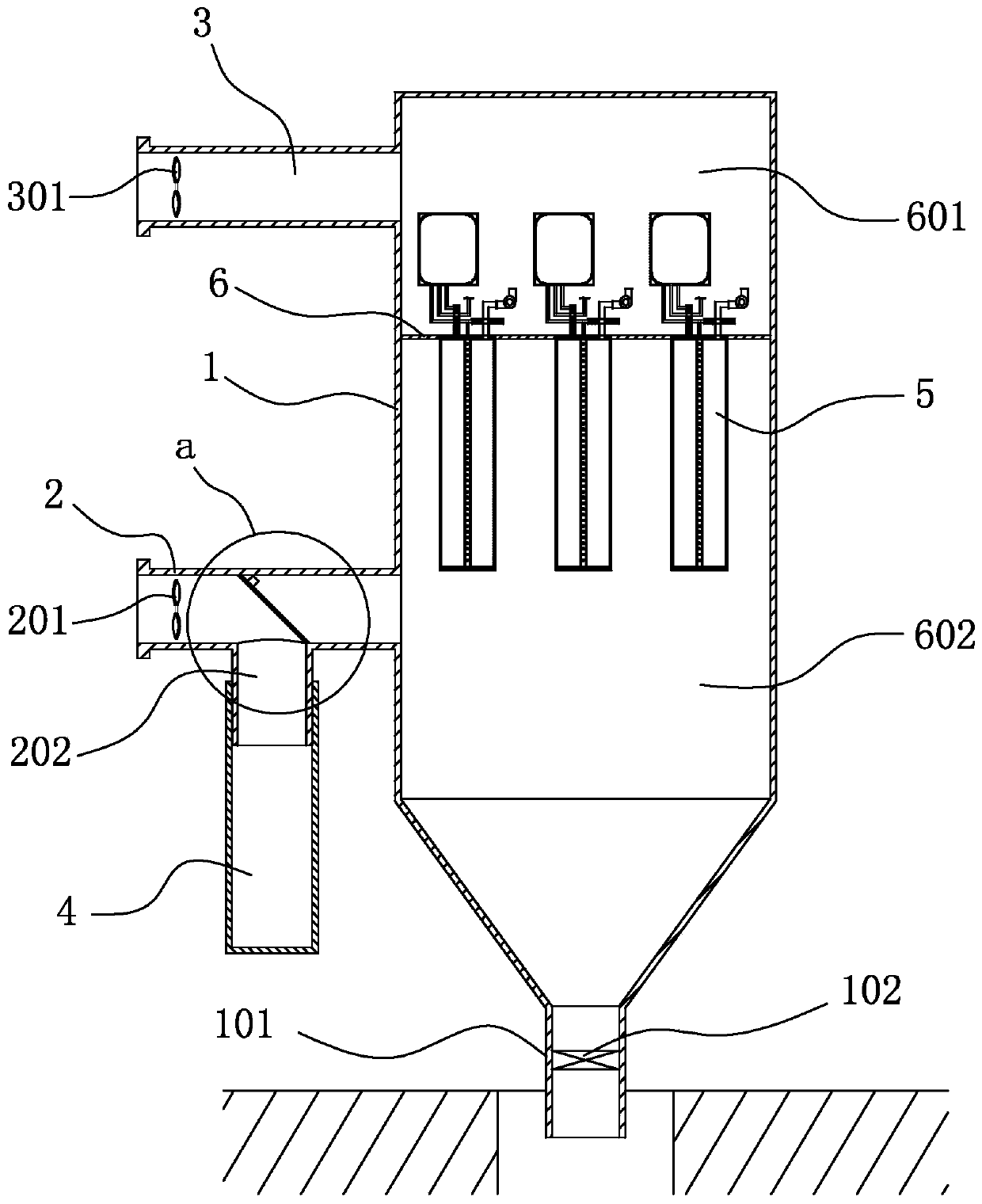

[0044] see Figure 1 to Figure 10 A kind of industrial air purification equipment described in this embodiment at least includes a box body 1, an air inlet pipe 2 and an air outlet pipe 3, and the air inlet pipe 2 and the air outlet pipe 3 are fixed laterally on the outer wall of the box body 1 and It communicates with the inner cavity of the box body 1, the air inlet pipe 2 is provided with an air intake fan 201, the air outlet pipe 3 is provided with an exhaust fan 301, and the box body 1 is provided with several filter assemblies 5, and the lower part of the box body 1 is formed by the upper To the tapered shape of the lower opening, the lower end of the box body 1 is provided with a second dust discharge pipe 101, the second dust discharge pipe 101 is connected and communicated with the box body 1, and a dust discharge valve 102 is arranged inside the second dust discharge pipe 101. The air inlet pipe 2 is provided with a first dust discharge pipe 202, the first dust disch...

Embodiment 2

[0061] see Figure 11 to Figure 19 A kind of industrial air purification equipment described in this embodiment at least includes a box body 1, an air inlet pipe 2 and an air outlet pipe 3, and the air inlet pipe 2 and the air outlet pipe 3 are fixed on the outer wall of the box body 1 and are connected to The inner chamber of the box body 1 is connected, the air inlet pipe 2 is provided with an air intake fan 201, the air outlet pipe 3 is provided with an exhaust fan 301, the box body 1 is provided with several filter assemblies 5, and the lower end of the box body 1 is provided with a second The dust discharge pipe 101 and the second dust discharge pipe 101 communicate with the box body 1 , and a dust discharge valve 102 is arranged in the second dust discharge pipe 101 .

[0062] The air inlet pipe 2 is provided with a primary dust removal mechanism, and the primary dust removal mechanism includes a filter box 9 , a transition pipe 10 , a positioning pipe 11 and an ash coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com