Large-diameter thin-wall small-bending-radius bent pipe with straight sections at two ends and hydraulic forming device and forming method thereof

A bending radius, hydroforming technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of buckling, poor dimensional accuracy and reliability of parts, easy elliptical mouth, etc., and achieve high yield and thinning rate. Low, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The above-mentioned hydroforming device is used to form the bent pipe, and the process is as follows:

[0058] 1. Select straight tube billet: such as Figure 5 As shown, the outer diameter of the straight tube blank 7 is smaller than the outer diameter of the final elbow 12, and the wall thickness of the straight tube blank 7 is greater than or equal to the wall thickness of the final elbow tube 12. The straight tube blank 7 can be a seamed tube or a seamless pipe.

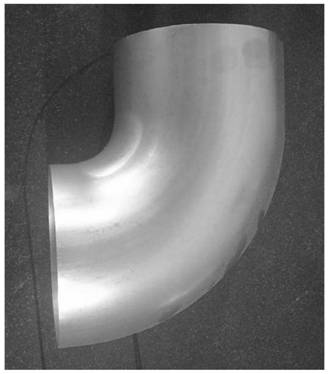

[0059] 2. CNC pipe bending: such as Image 6 As shown, the straight pipe billet 7 is bent by numerical control to form a bent pipe billet 8 .

[0060] In this embodiment, the bending radius of the bent pipe billet is R=1.2D, D is the outer diameter of the bent pipe billet, and the expansion of the bent pipe billet is 18%.

[0061] 3. Put it into the mold: such as Figure 7 As shown, the bent pipe blank 8 is put into a hydroforming die, generally the lower die 2 . When the bent pipe billet 8 is put in,...

Embodiment 2

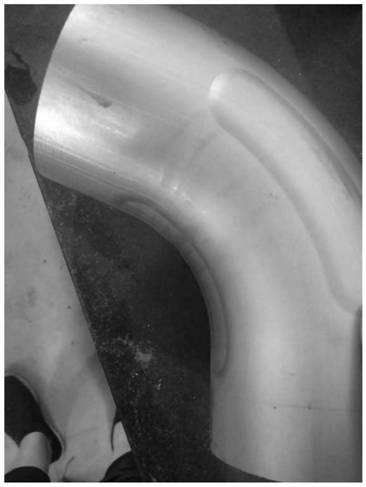

[0068] The difference from Example 1 is that the bent pipe product has changed from one bend to two bends, and so on for multiple bends.

[0069] 1. Select straight tube billet: such as Figure 5 shown.

[0070] 2. CNC pipe bending: such as Figure 13 shown.

[0071] 3. Put it into the mold: such as Figure 14 shown.

[0072] 4. Mold closing: such as Figure 8 shown.

[0073] 5. Push head feed: such as Figure 9 shown.

[0074] 6. Liquid filling and pressurization: such as Figure 9 shown.

[0075] 7. Opening the mold and taking the tube: after opening the mold, if Figure 15 shown.

[0076] 8. Cutting: It can be cut into one elbow with two bends, or cut into two elbows with only one bend.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com