MEMS microphone and manufacturing method thereof

A manufacturing method and microphone technology, applied in the directions of loudspeakers, electrostatic transducer microphones, sensors, etc., can solve the problems of poor acoustic performance and low signal-to-noise ratio of MEMS microphones, so as to improve product performance, shorten lamination time, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

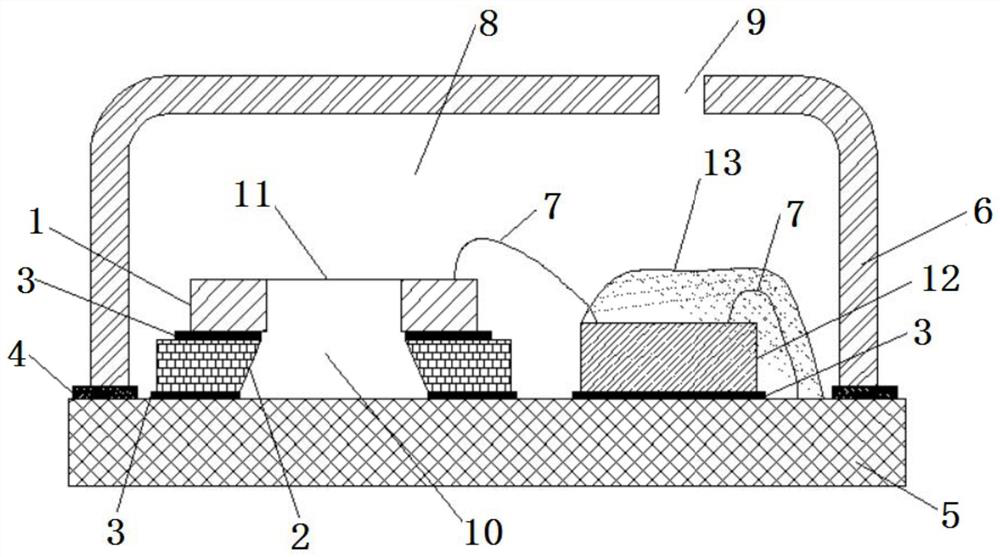

[0048] A method of manufacturing a MEMS microphone, comprising the following steps,

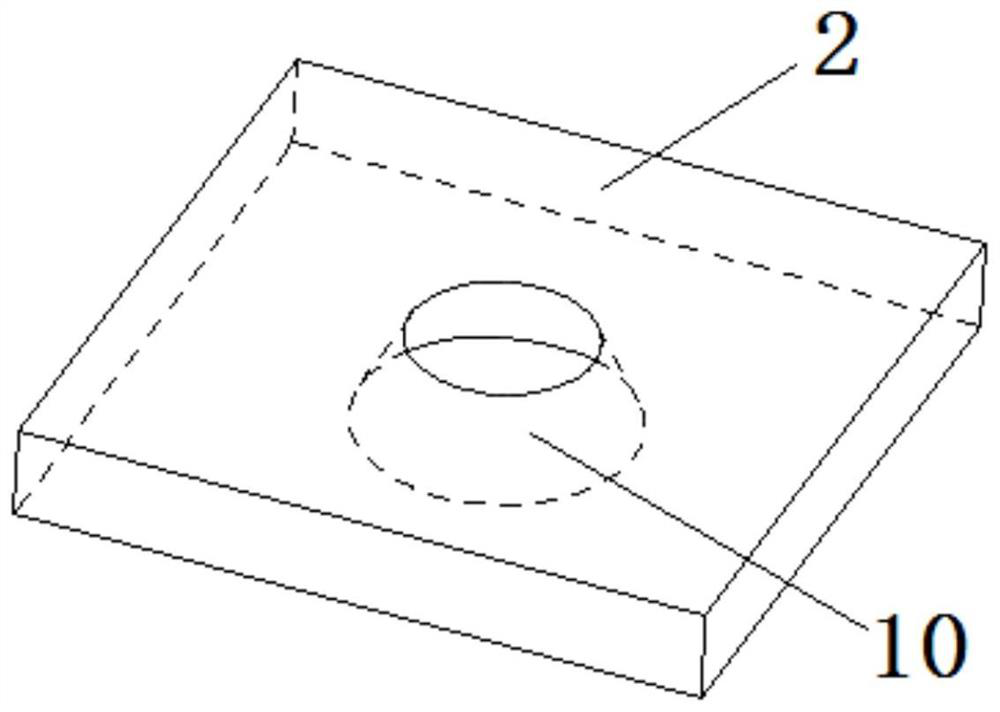

[0049] Step 1, bonding the MEMS chip 11 and the base 2 together to form a combined chip with a rear cavity 10;

[0050] In step 1, two process types of wafer to wafer and chip to wafer are used for bonding the MEMS chip 11 and the base 2;

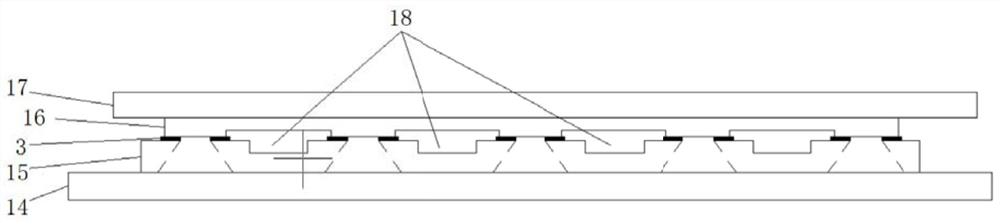

[0051] Such as image 3 and Figure 4 As shown, it is a wafer to wafer process type, and the MEMS chip 12 and the base 2 are all wafers, such as image 3 As shown, it may be first to place the small hole end of the base wafer 15 upward on the carrier 14, then suck the MEMS chip wafer 16 through the suction nozzle 17, and place the MEMS chip wafer 16 on the base wafer 15 in an aligned position. The above is pressed and fixed by the fixing glue 3. After the pressing is completed, the wafer cutting machine is used to cut at the position of the dicing line 18 to form a single combined chip, such as Figure 7 shown.

[0052] Such as Figure 4 As shown, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com