Downhole hydraulic sonic inlet screen and lift string

A hydraulic and liquid feeding technology, applied in drilling pipes, casings, drilling equipment, etc., can solve the problems of high cost, easy pollution to the environment, not meeting the target requirements of green production in oil fields, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

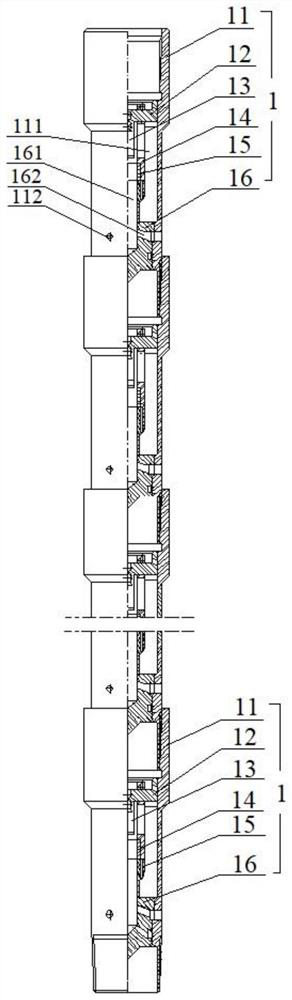

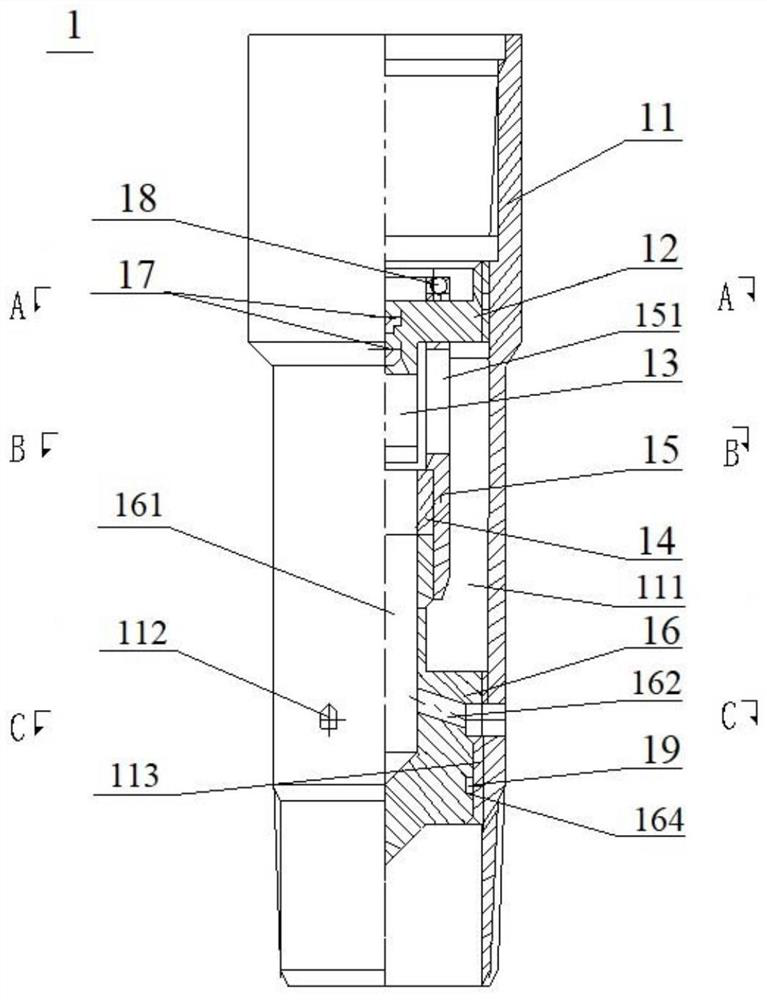

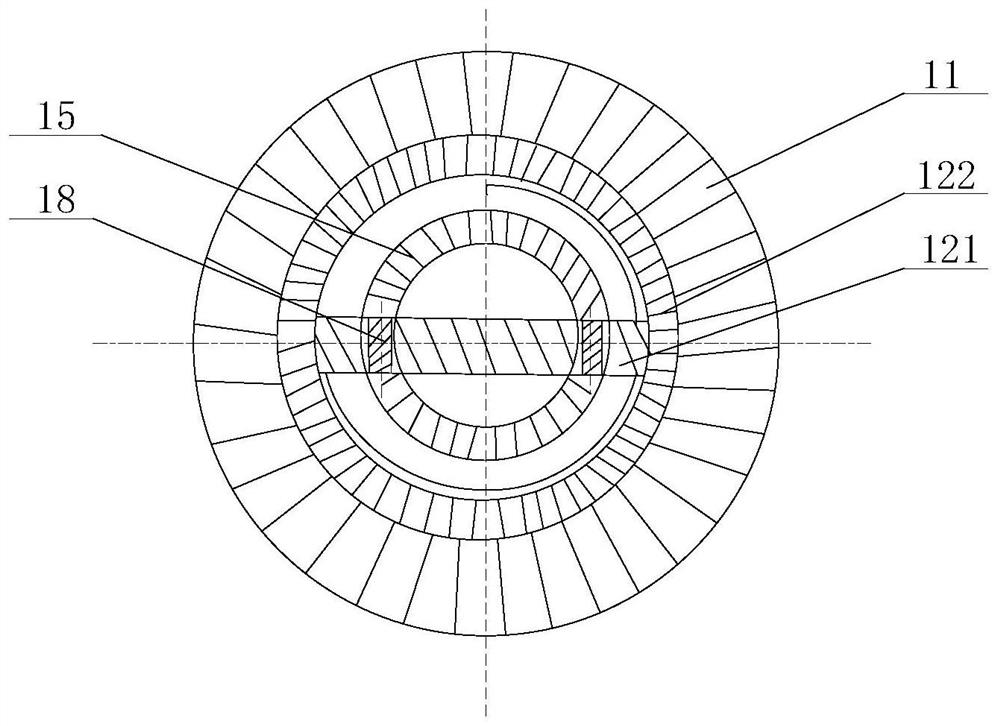

[0044] Before further detailed description of the embodiments of the present invention, the orientation nouns involved in the embodiments of the present invention, such as "upper", "lower", "upper", "lower", "outer", "upper", "lower" ", etc., both with figure 1 or figure 2 The orientation shown in the figure is a reference, and is only used to clearly describe the downhole hydraulic acoustic wave inlet screen and the lift string according to the embodiment of the present invention, and does not have the meaning of limiting the protection scope of the present invention.

[0045] Unless otherwise defined, all technical terms used in the embodiments of the present invention have the same meaning as commonly understood by those skilled in the art. In order to make the technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

[0046] In orde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com