Preparation method of fluoride and intermediate thereof

A compound, thionyl fluoride technology, applied in the field of preparation of fluoride and its intermediates, can solve the problems of strong corrosion, cumbersome operation, and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

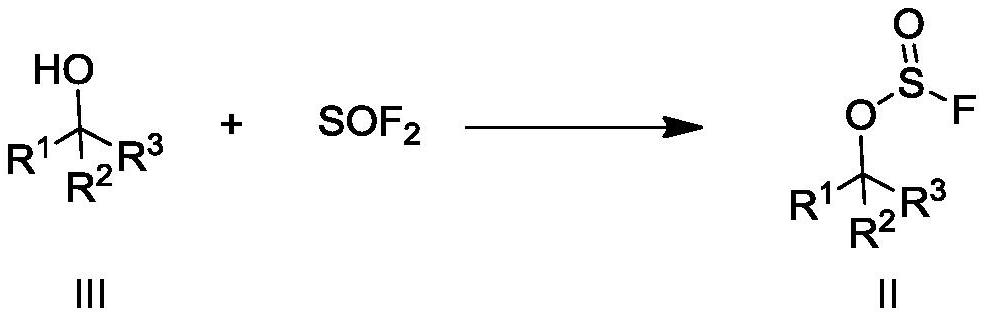

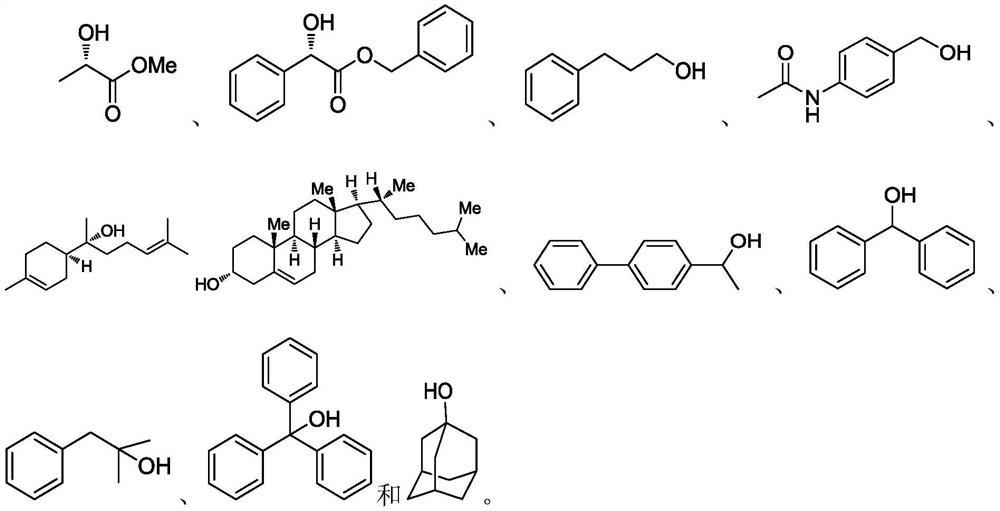

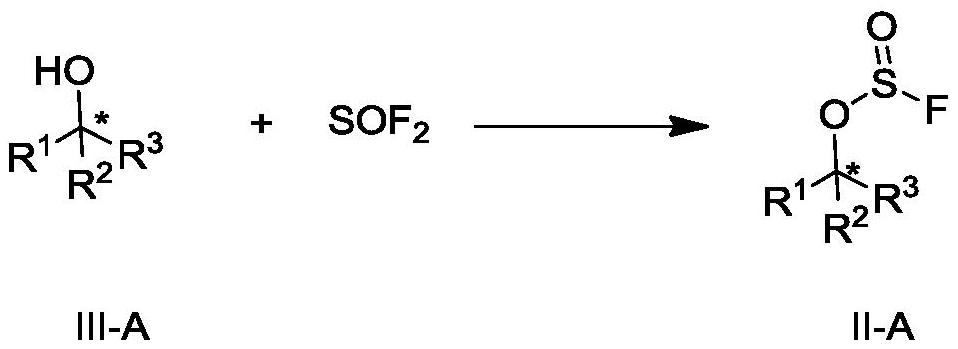

Method used

Image

Examples

Embodiment 1

[0124] [chemical formula 3]

[0125]

[0126] Select optically active [chemical formula 3] α-hydroxy carboxylate methyl ester as substrate, in the reactor, charge the [chemical formula 3] α-hydroxy carboxylate of 10.6g (100mmol, 1.00eq, photochemical purity more than 98.0%ee) Acetate methyl ester, and 11.1g (110mmol, 1.1eq) of triethylamine, after adding 100ml of solvent DMF (N,N-dimethylamide) and stirring at -15°C, then slowly bubbling 9.89g of (115mmol, 1.15eq) of SOF 2 Gas (thionyl fluoride gas), the internal temperature will increase with the amount of gas blown in. After 1h, intermediate II-1 is obtained. After testing, 19 FNMR (376MHz, reference substance is trifluorotoluene) δ62.11, 60.32 (two fluorine peaks).

[0127]

[0128] The mixed solution was heated to 100° C., and the reaction was completed after 2 hours, and the reaction conversion rate reached more than 95%. Then, the reaction-terminated liquid was directly distilled under reduced pressure, and the ...

Embodiment 2

[0145] Select optically active α-hydroxycarboxylate methyl ester as substrate, and charge [chemical formula 3] α-hydroxycarboxylate methyl ester and 5.55g (50mmol, 0.5eq) of triethylamine, then add 100ml of solvent DMF (N,N-dimethylamide) and stir evenly at -15°C, then slowly bubble 9.89g (115mmol, 1.15eq ) of SOF 2 Gas (thionyl fluoride gas), the internal temperature will increase with the amount of gas blown in. After 1 hour, the mixed solution is heated to 100 ° C. After 2 hours of reaction, the reaction conversion rate reaches more than 95%.

[0146] Then, the reaction-terminated liquid was directly distilled under reduced pressure, and the temperature of the distilled oil bath was 80° C., thereby obtaining 6.3 g of liquid (R)-methyl 2-fluoropropionate fraction product of [Chemical Formula 4]. The recovery rate was 60%. The chemical purity of the distillate was 1 The photochemical purity was above 95% as calculated by H NMR.

[0147] (R)-Methyl 2-fluoropropionate 19 F...

Embodiment 3

[0149]Select optically active [chemical formula 3] α-hydroxy carboxylate methyl ester as substrate, in the reactor, charge the [chemical formula 3] α-hydroxy carboxylate of 10.6g (100mmol, 1.00eq, photochemical purity more than 98.0%ee) Acetate methyl ester and 11.1g (110mmol, 1.1eq) of triethylamine, after adding 100ml of solvent DMF (N,N-dimethylamide) and stirring at -15°C, then slowly bubbling 9.89g ( 115mmol, 1.15eq) of SOF 2 Gas (thionyl fluoride gas), the internal temperature will increase with the amount of gas blown in. After 1 hour, the mixed solution is heated to 100 ° C. After 2 hours of reaction, the reaction conversion rate reaches more than 95%.

[0150] Then, the reaction-terminated liquid was directly distilled under reduced pressure, and the temperature of the distilled oil bath was 80° C., thereby obtaining 7.3 g of liquid (R)-methyl 2-fluoropropionate fraction product of [Chemical Formula 4]. The recovery rate was 65%. The chemical purity of the distillat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com