Finishing improvement method for turning surface quality of rectifier assembly matching part

A technology for rectifiers and parts, which is applied in the field of finishing and improving the turning surface quality of rectifier assembly and matching parts, to achieve the effects of avoiding additional repair work, obvious cleaning effect, and reduced assembly cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

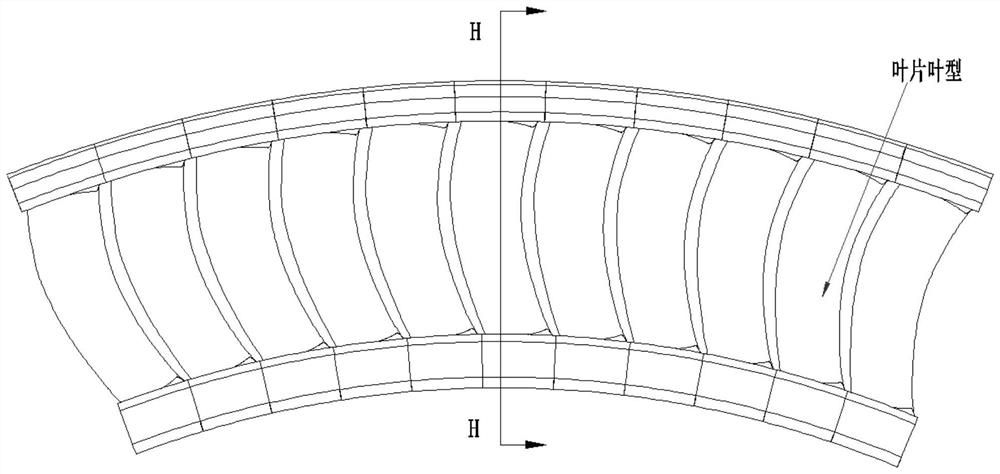

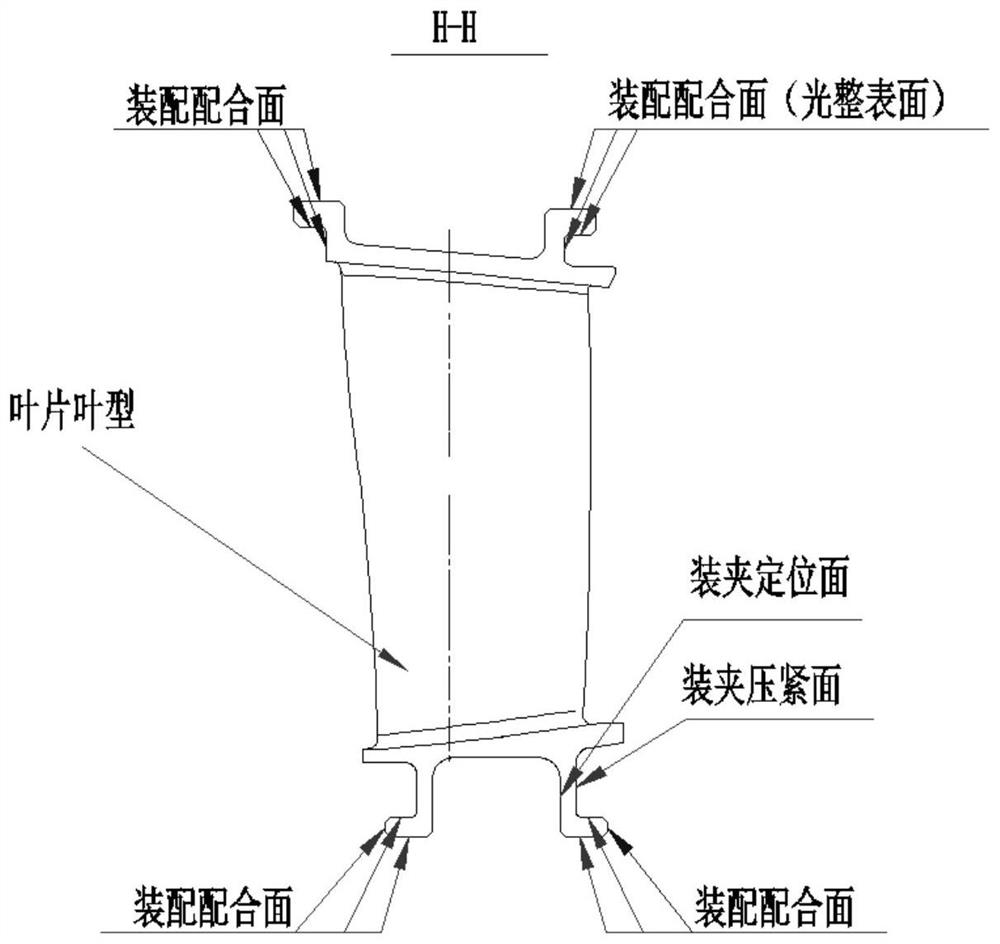

[0026] Such as Figure 1 to Figure 6 As shown, a method for improving the surface quality of the turning surface of the rectifier assembly mating part, including the following steps:

[0027] Step 1, apply adhesive tape to each leaf-shaped part of the rectifier part 1 that does not need to be ground, and then use nylon rope to bind each leaf-shaped part where the tape is pasted to prevent the tape from being dragged and dropped during work;

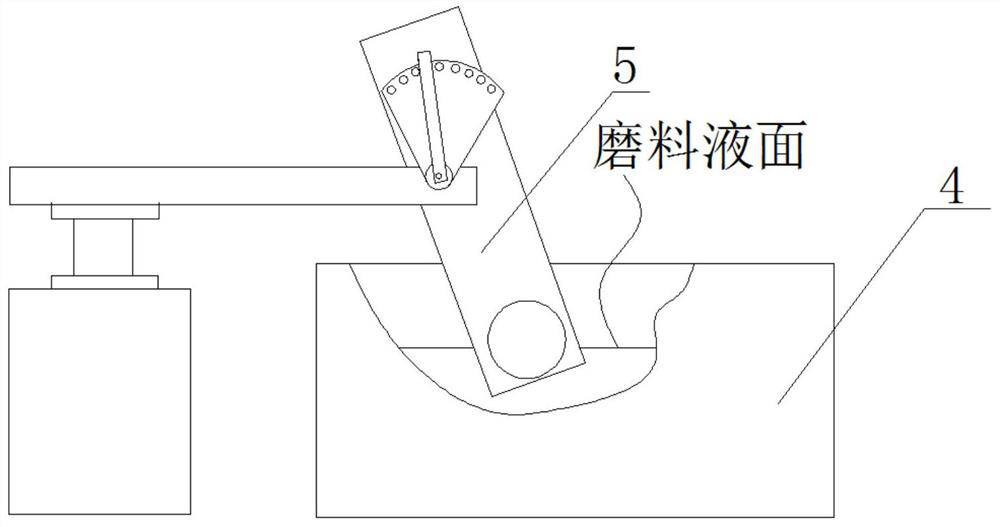

[0028] Step 2, the finishing equipment 5 adopts BJG-CZ300 fork-shaft free mold finishing equipment, select the brown corundum spherical coarse abrasive with a size of φ2mm and pour it into the material box 4 of the finishing equipment 5, and the height is controlled to be 2 / of the container of the material box 4 3. Add tap water to a height equal to the height of the abrasive, start material box 4, perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com