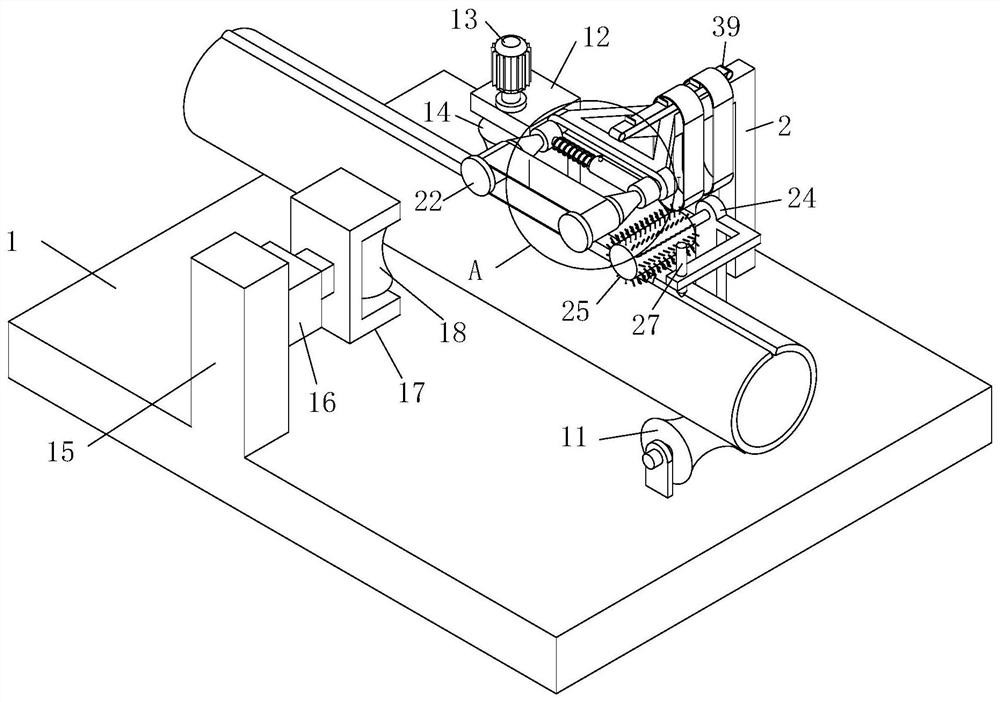

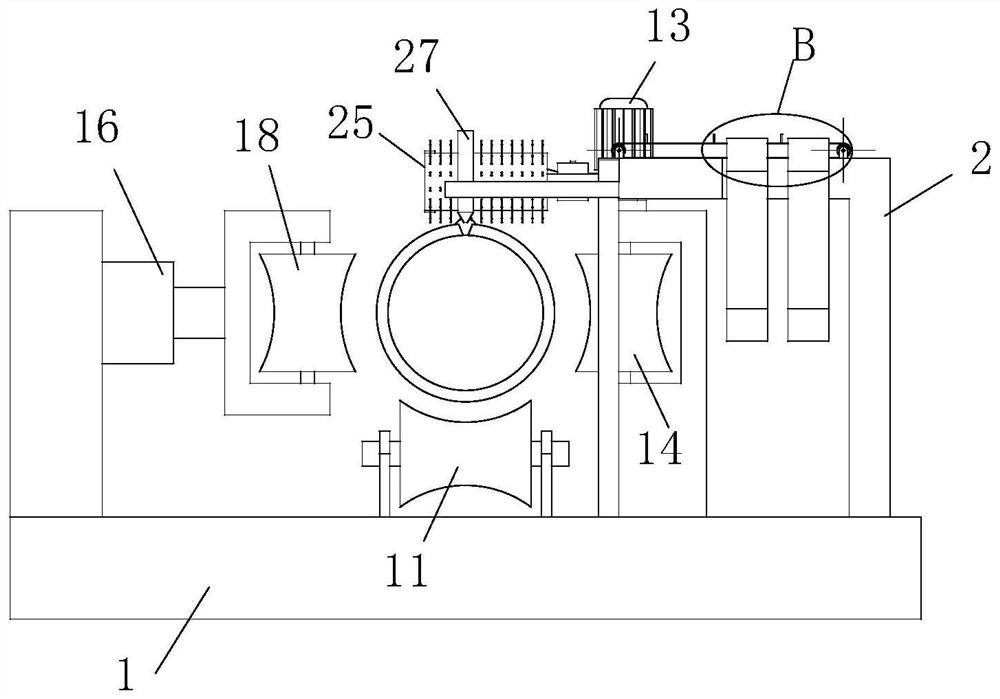

Horizontal pipe welding machine capable of automatically grinding weld joints

A horizontal welding and grinding technology, applied in the direction of grinding machines, abrasive belt grinders, welding equipment, etc., can solve the problems of abrasive belt scratches, reduce the service life of abrasive belts, etc., and achieve the effect of reducing downtime, reducing residue and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

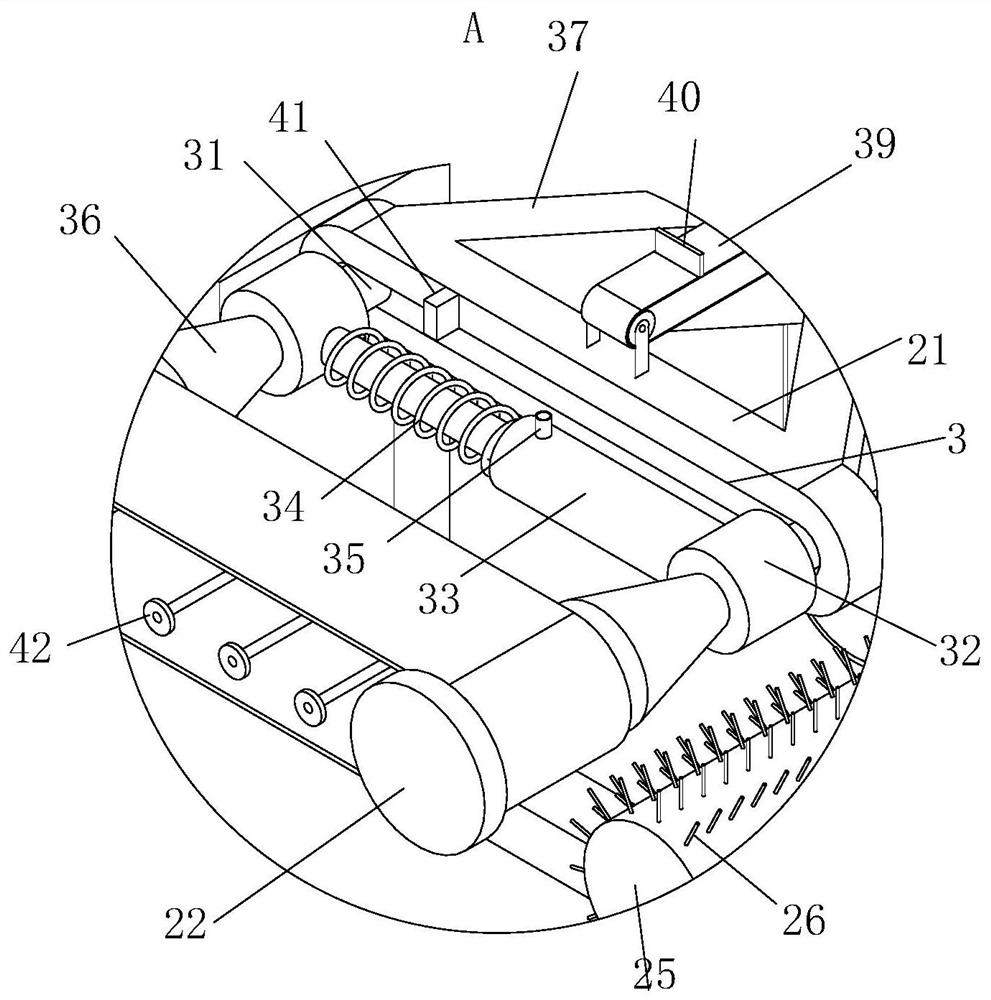

[0024]As an embodiment of the present invention, a group of ring-shaped steel ropes 28 are evenly distributed on the outer periphery of the cleaning roller 25, and the steel ropes 28 are fixedly connected with the bristles 26; a group of steel balls 29 are slidably connected on the steel ropes 28, and the steel balls 29 are Hollow, and the steel ball 29 is filled with iron sand; the rotation of the bristles 26 and the steel rope 28 is driven by the cleaning roller 25, so that the steel ball 29 on the steel rope 28 is thrown away from the center of the cleaning roller 25 under the action of centrifugal force, so that the steel ball 29 Constantly beat the welding slag and welding skin on the welding seam to increase the shedding efficiency of welding slag and welding skin, and further reduce the wear of the abrasive belt 23. The welding residual stress can further improve the welding quality of the steel pipe.

[0025] As an embodiment of the present invention, the crossbar 21 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com