Device for detecting thickness of foam material sheet and rejecting defective foam material sheet

A technology of thickness detection and blanks, which is applied in the field of 3C blanks detection, can solve the problems that are difficult to apply to large-scale continuous production, easily damaged strips or similar good and bad products are mixed in, so as to facilitate the removal of blanks and detection The position is stable and controllable, and the effect of increasing coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]The present invention will be described in further detail below in conjunction with the accompanying drawings. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

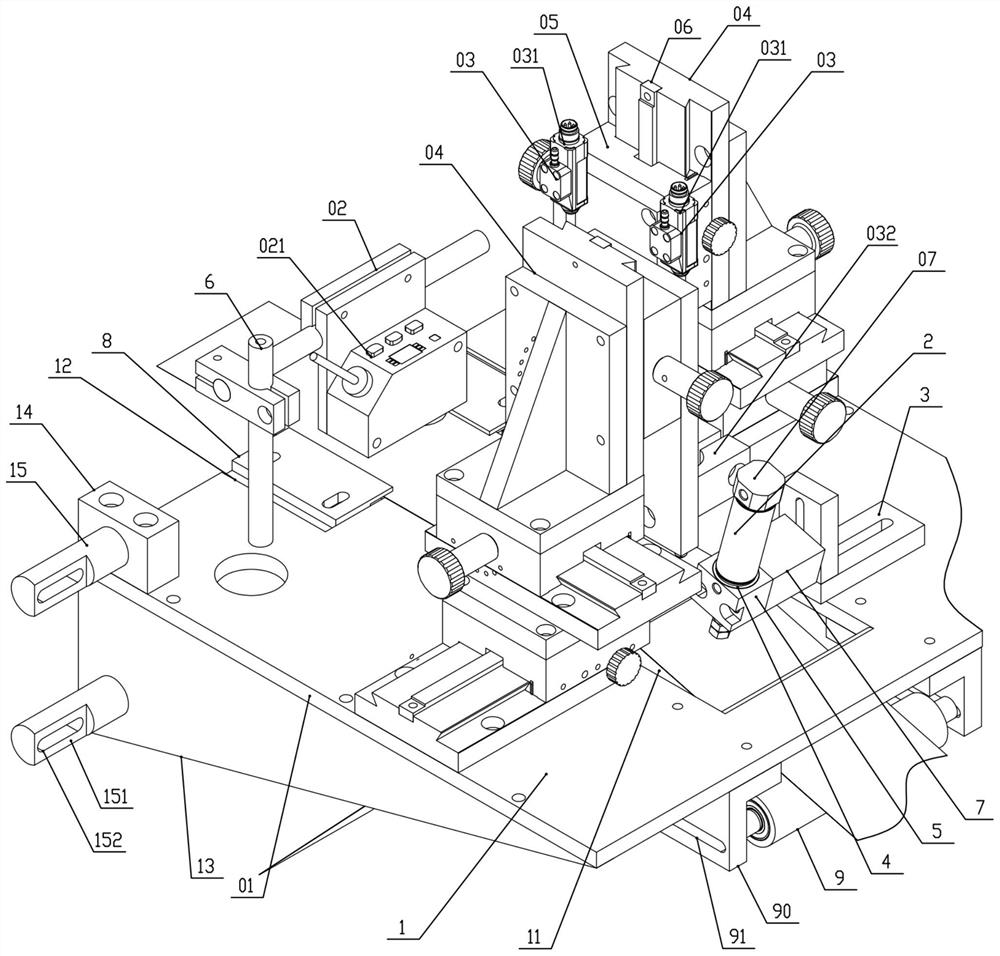

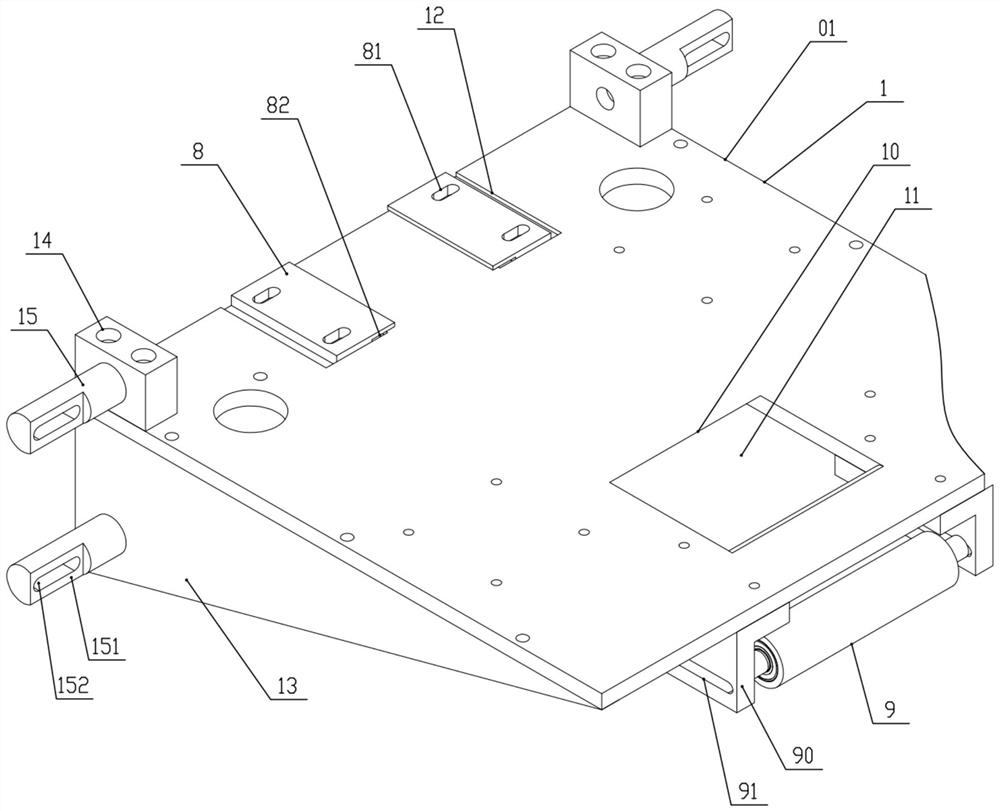

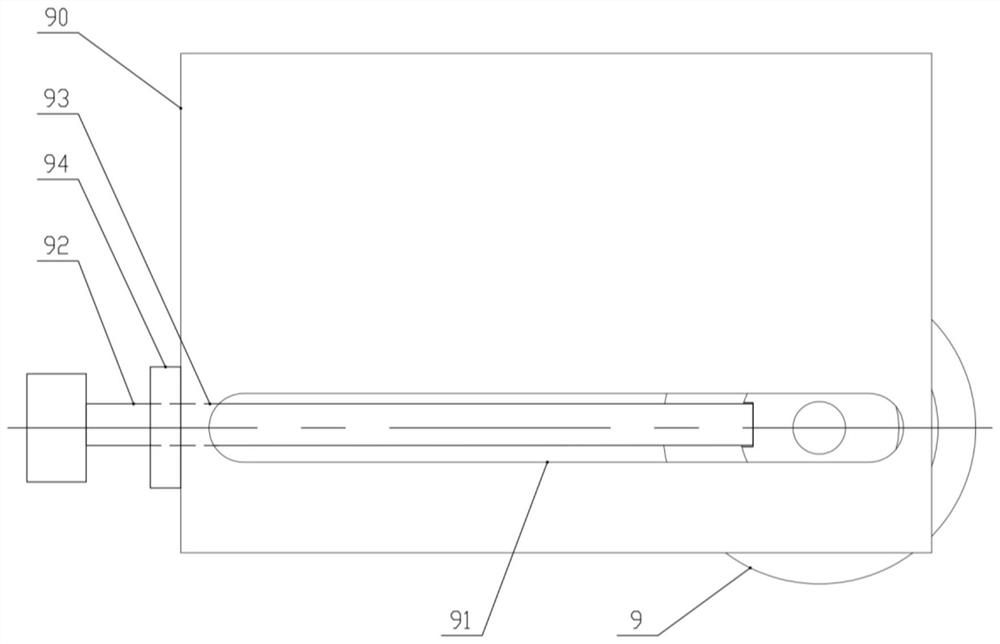

[0040] Figure 1 to Figure 7 A device for detecting the thickness of a foam sheet and rejecting defects according to an embodiment of the present invention is schematically shown. As shown in the figure, the device includes a base 01, a position detection component 02, two thickness detection components 03 and a rejector 07;

[0041] The abutment 01 includes a horizontal reference plate 1, the right end of the reference plate 1 is provided with a rectangular picking hole 11, and the left end of the picking hole 11 is a stripping knife 10; the left end of the reference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com