Hot melt adhesive formula

A hot-melt adhesive and formula technology, applied in the directions of adhesives, sol preparation, colloid chemistry, etc., can solve the problems affecting processing efficiency and quality, low mixing and mixing efficiency, etc., to improve the effect and efficiency, avoid uneven mixing, and improve mixing. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

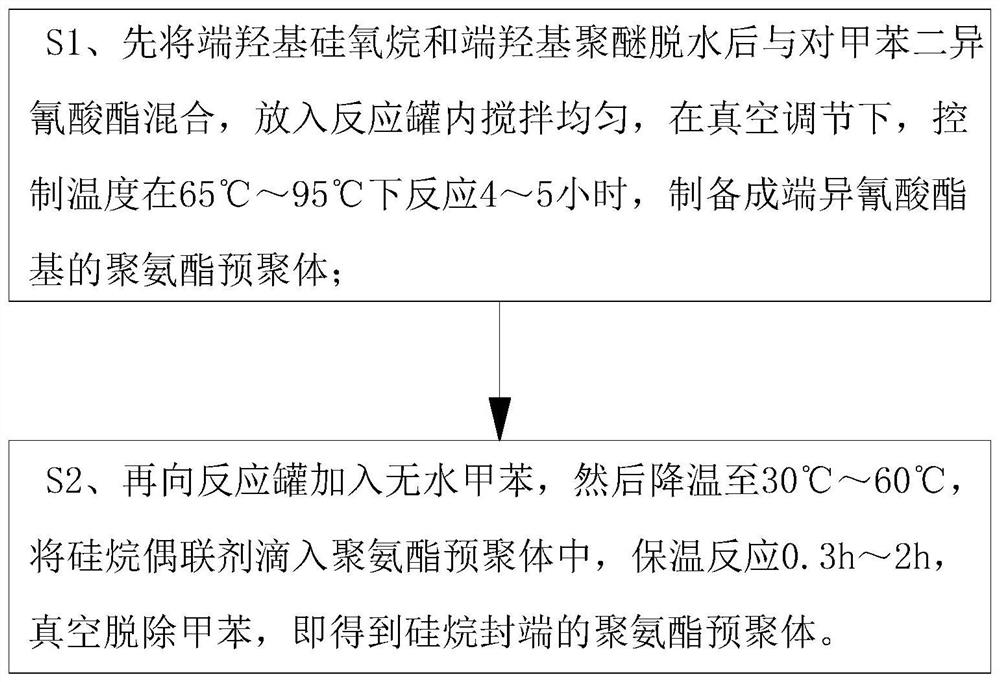

[0033] The preparation method of the silane-terminated polyurethane prepolymer comprises the following steps:

[0034] S1. First dehydrate the hydroxy-terminated siloxane and hydroxy-terminated polyether, mix them with p-toluene diisocyanate, put them into the reaction tank and stir evenly, and under vacuum regulation, control the temperature at 65°C to 95°C for 4 to 5 hours. , to prepare a polyurethane prepolymer with terminal isocyanate groups;

[0035] S2. Add anhydrous toluene to the reaction tank, then lower the temperature to 30°C-60°C, drop the silane coupling agent into the polyurethane prepolymer, keep it warm for 0.3h-2h, and remove the toluene in a vacuum to obtain silane-capped Polyurethane prepolymer;

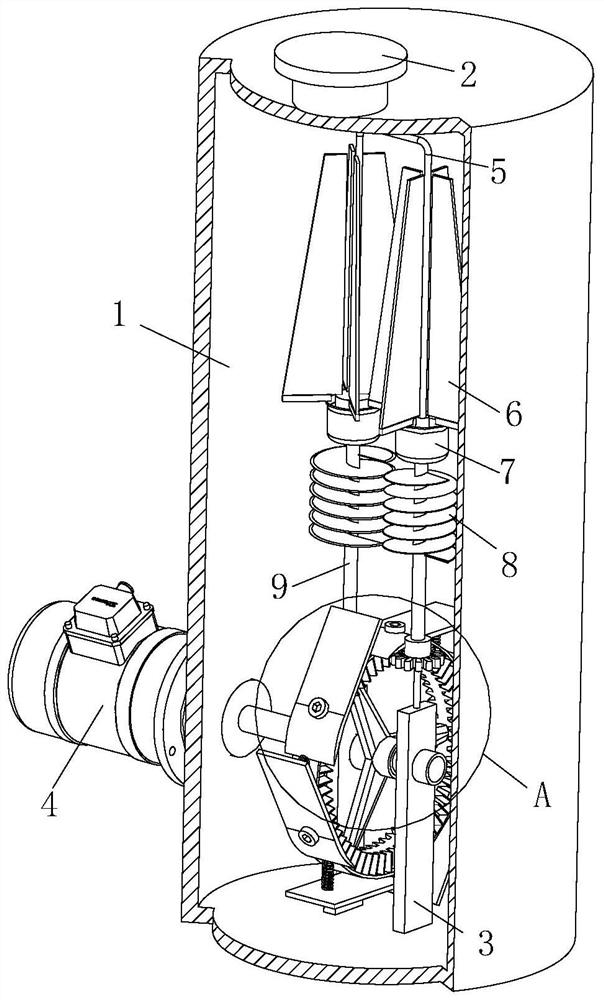

[0036]Wherein, the reaction tank includes a tank body 1 and a stirring device inside thereof, the upper end of the tank body 1 is provided with a feed inlet 2, and the lower end of the tank body 1 is provided with a discharge port; the stirring device includes a t...

Embodiment approach

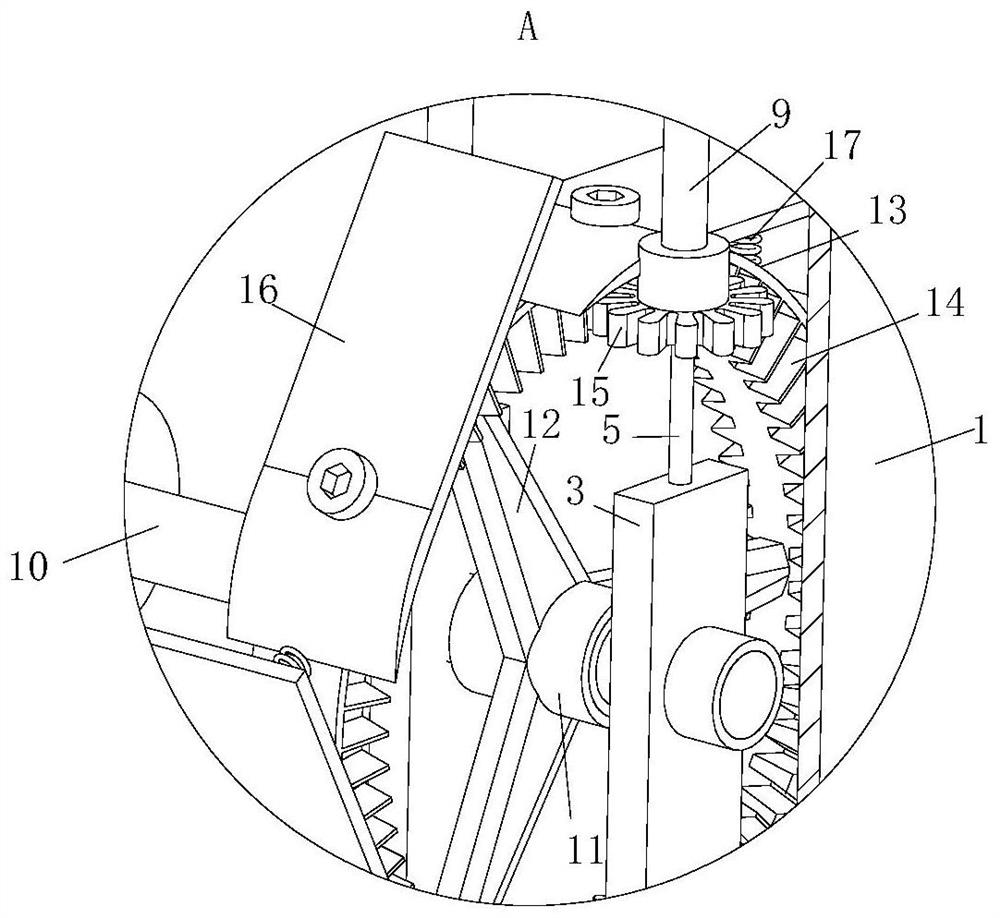

[0040] As an embodiment of the present invention, a plurality of obliquely arranged elastic plates 16 are arranged at intervals outside the annular frame 13, one end of the elastic plates 16 is fixedly connected to the annular frame 13, and the other end of the elastic plates 16 is arranged in a cantilever manner. And a spring 17 is arranged between the elastic plate 16 . The arrangement of the elastic plate 16 can further improve the vertically inward disturbing ability of the ring frame 13, and then when the elastic plate 16 rotates to the lower side of the ring frame 13, it can scrape the material deposited in the lower layer, thus avoiding the problem of material self-stratification , to improve the uniformity of mixing.

[0041] As an embodiment of the present invention, spiral stirring teeth 8 are provided on the outer tube 9 close to the side of the mounting plate 7, and the rotation direction of the two spiral stirring teeth 8 is opposite; the lower end of the spiral s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com