Filament winding alternation-type filtering device for textile waste gas

A filter device and silk rolling technology, which is applied in the direction of dispersed particle filtration, transportation and packaging, and separation of dispersed particles, and can solve problems such as difficult filtration process, air pollution, and harm to human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

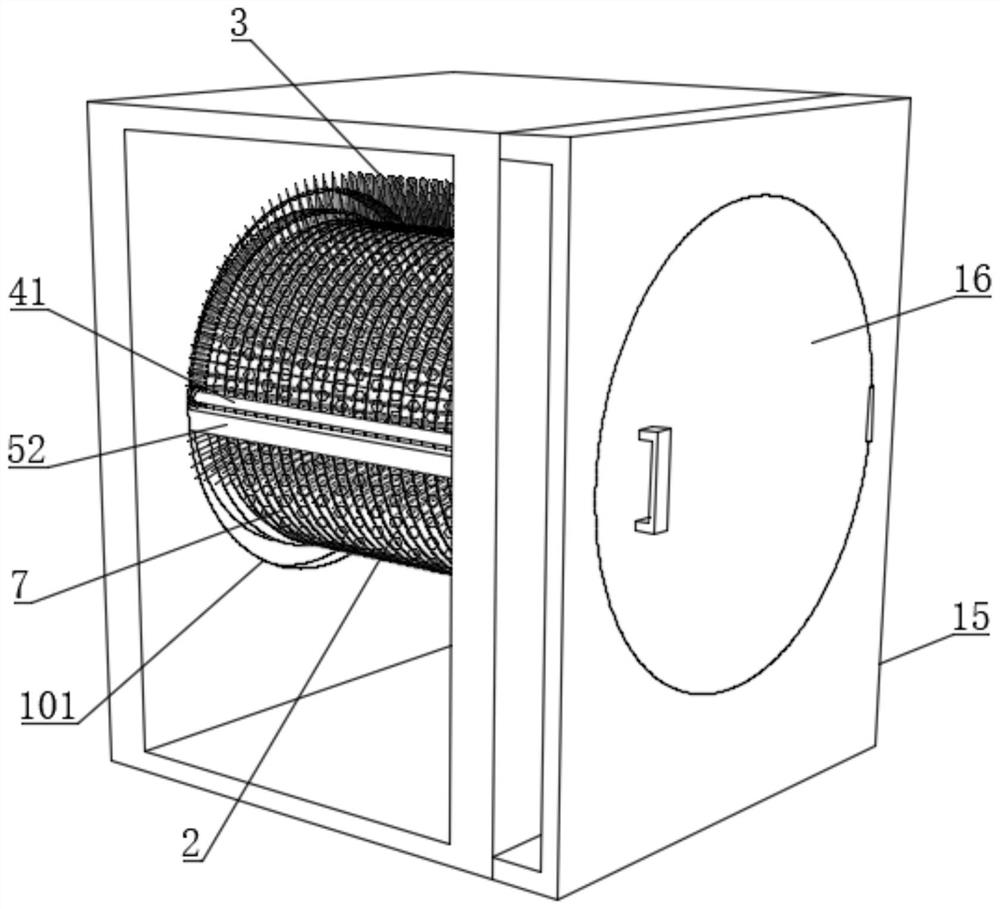

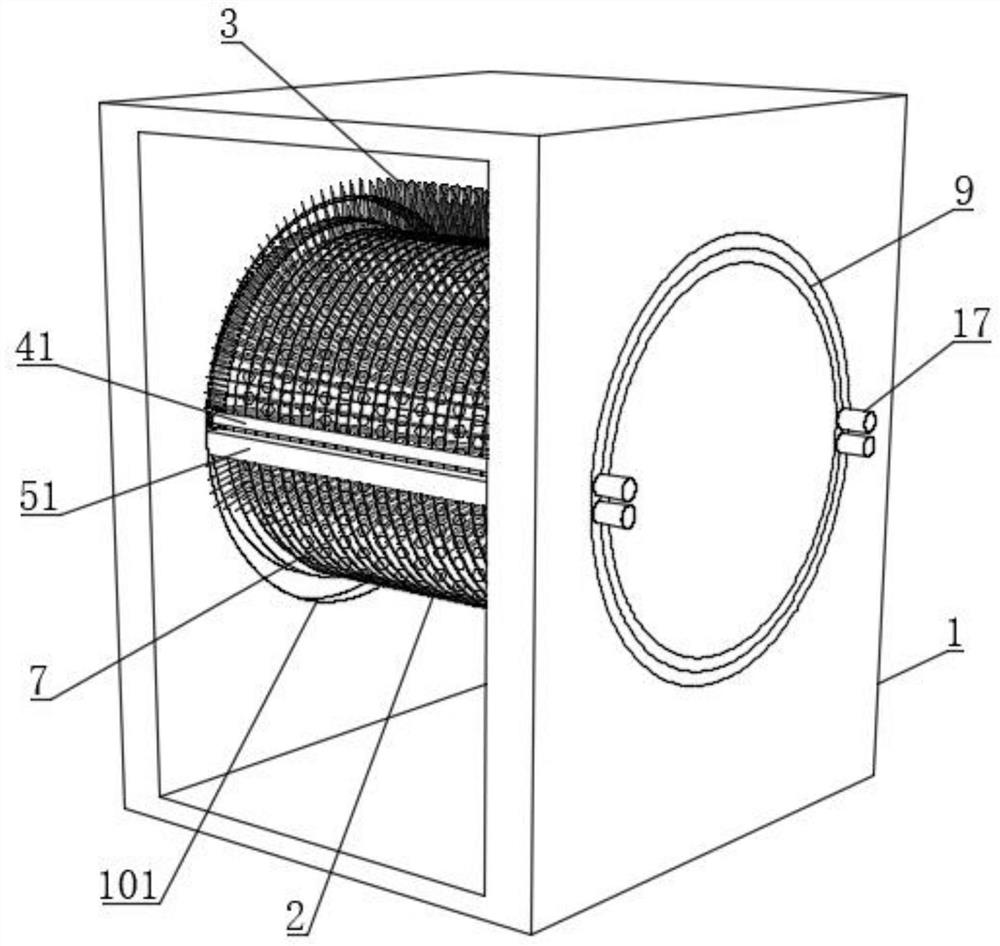

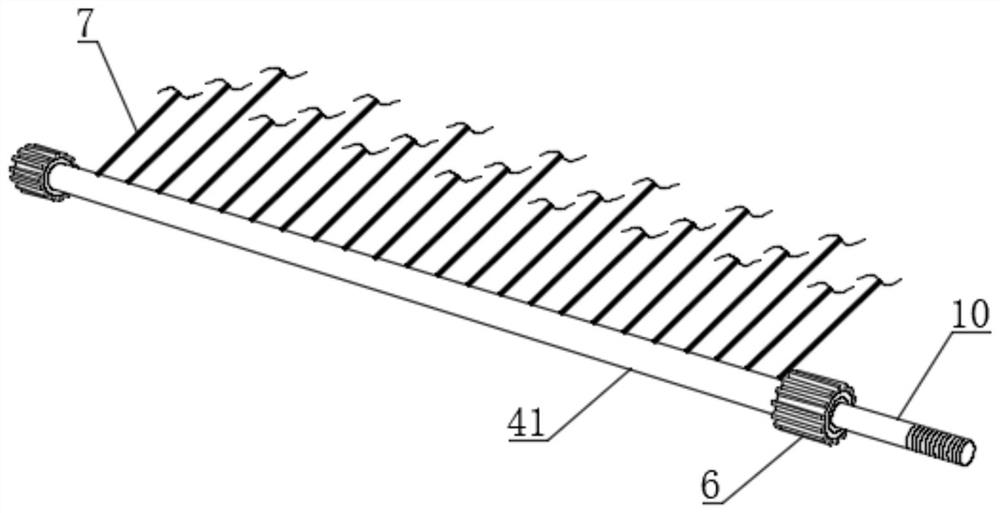

[0042] see figure 1 and Figure 4 , a coiled thread alternate filter device for textile waste gas, including a device body, the device body includes a filter box 1, the inside of the filter box 1 contains clean water, and a filter cartridge 2 is fixedly connected to the inner wall of the filter box 1, The outer end of the filter cartridge 2 is fixedly connected with a plurality of uniformly distributed soft filter brushes 3, and the outer side of the filter cartridge 2 is provided with a main winding rod 41, a secondary winding rod 42, a main arc plate 51 and an auxiliary arc plate 52, and the main arc plate 51 and the secondary arc plate 52 are respectively located between the main scroll bar 41 and the secondary scroll bar 42, the main scroll bar 41 and the secondary scroll bar 42 have the same size and shape, the main arc plate 51 and the secondary arc plate 52 have the same size and shape, and the main scroll bar 41 and the secondary arc plate 52 have the same size and sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com