Motor iron core insulation paper assembling equipment and method thereof

A technology for iron core insulation and assembly equipment, applied in laying solid insulation and other directions, can solve the problems of low degree of automation, low paper loading efficiency, difficult to assemble grooves of different sizes, etc., to achieve efficient mechanism operation, improve work efficiency, and improve location. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

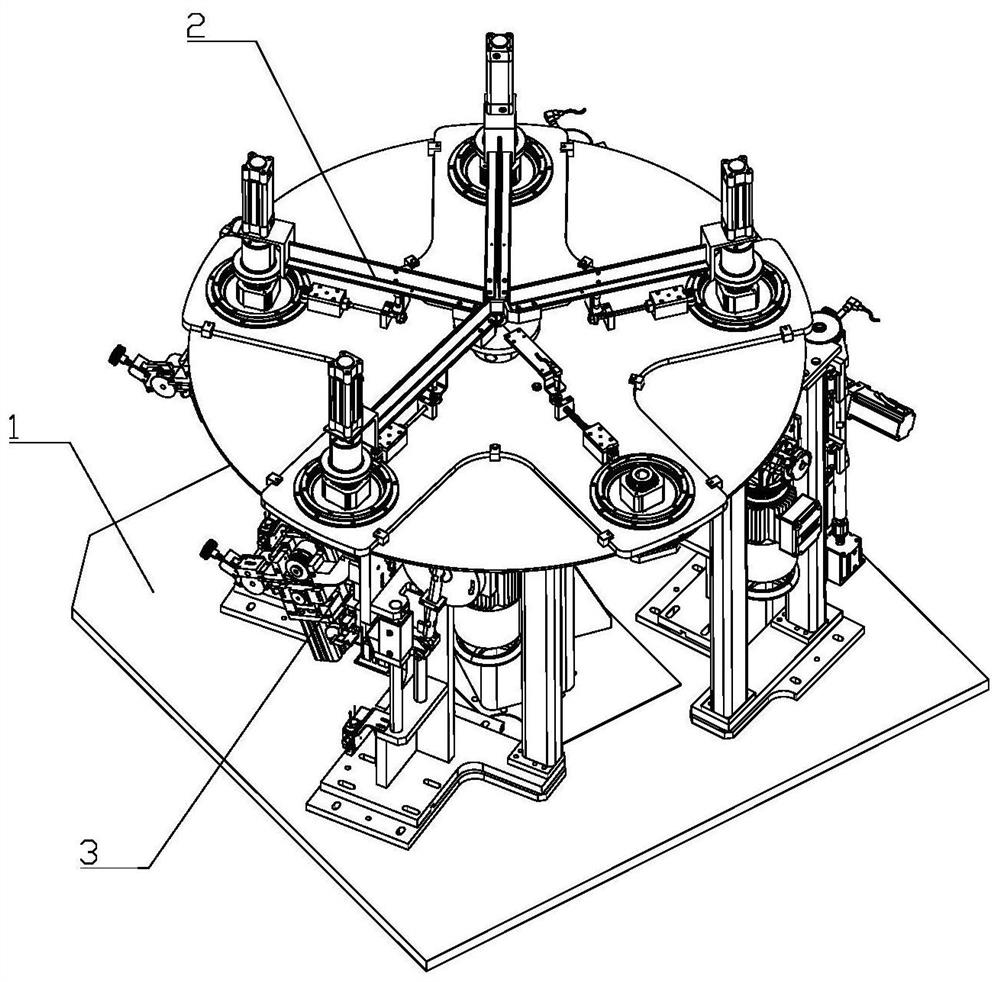

[0030] Such as figure 1 As shown, a motor core insulating paper assembly equipment includes a frame 1, a rotating circulation device 2 and an insulating paper assembly device 3 installed on the substrate, and the rotating circulation device 2 is provided with a processing station and a loading and unloading station. The paper assembly device 3 is provided with multiple groups, and the insulating paper assembly device 3 corresponds to the processing station of the rotating circulation device 2; the rotating circulation device 2 is used to realize the turnover and rotation after the iron core is positioned, and the insulating paper assembly device 3 It is used to cut the insulating paper and assemble it into the slot of the iron core.

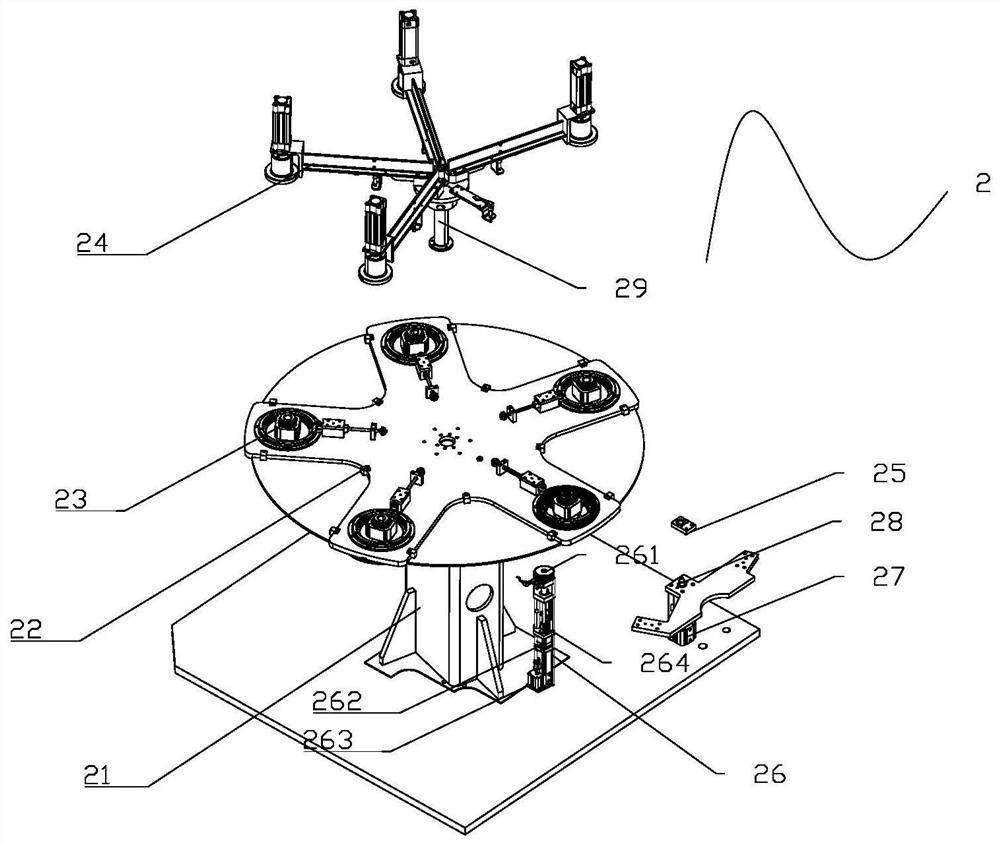

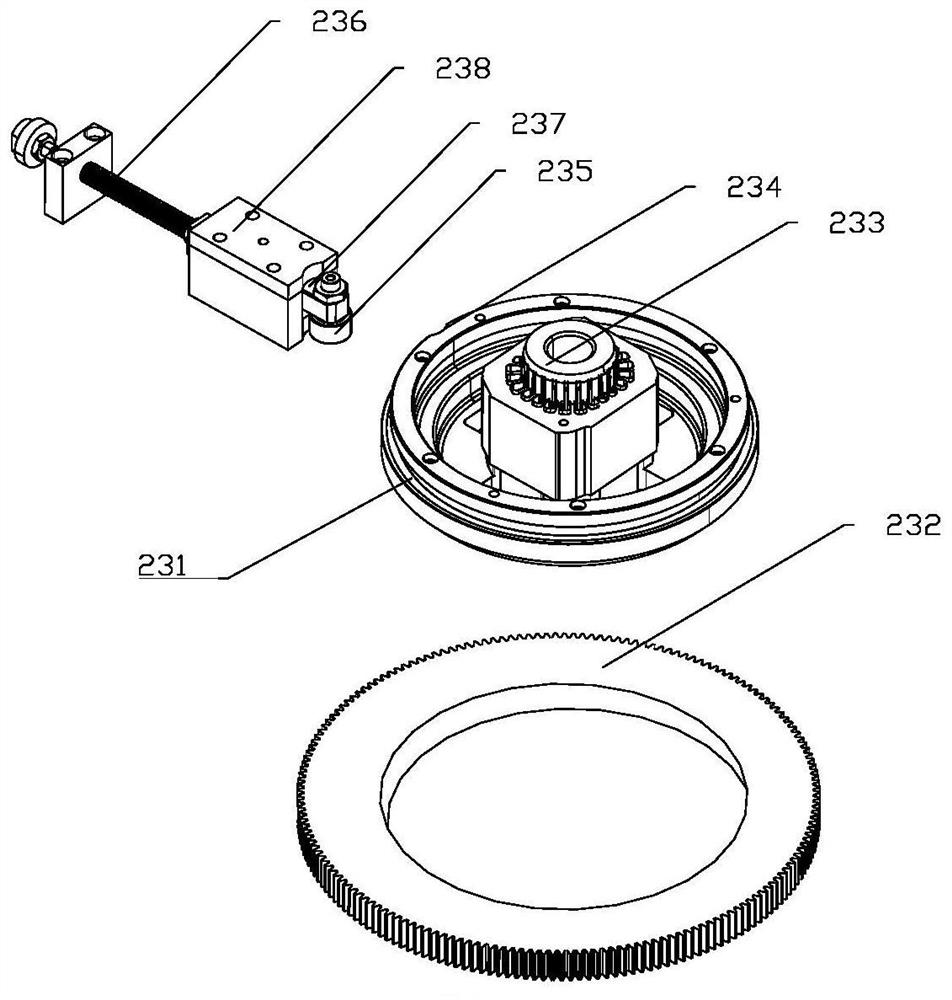

[0031] Such as figure 2 and image 3As shown, the rotating circulation device 2 includes a pillar 21, a divider, a disc 22, a fixture assembly 23, a pressing assembly 24 and a rotating assembly 26; the pillar 21 is fixed on the frame, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com